Efficiently-degradable oil sand tailing flocculating agent and preparation method thereof

A flocculant and oil sand technology, applied in the field of material science, can solve problems such as difficult uniform mixing and photodegradation effects, and achieve excellent flocculation function, high efficiency, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

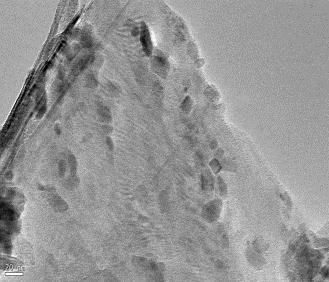

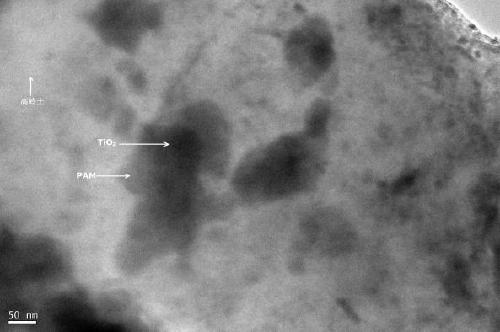

[0034] 1. Preparation of nano-titanium dioxide inorganic composite particles: nano-titanium dioxide inorganic composite particles were prepared by sol-gel method with nano-titanium dioxide and kaolin;

[0035] 2. Under ultraviolet light, acrylamide monomer polymerization is initiated on the surface of the obtained nano-titanium dioxide inorganic composite particles to obtain the oil sand tailings flocculant.

Embodiment 1

[0038] Step 1: Take kaolin, then add TiO 2 For the precursor, ethylene glycol methyl ether was used as a dispersant and ultrasonically dispersed for 15 minutes; wherein, according to the ratio of solid to liquid, kaolin: titanium dioxide precursor: ethylene glycol methyl ether = 10.0g: 0.52g: 25.0mL.

[0039] Step 2: Put the ultrasonicated liquid in step 1 into a closed blast drying oven and dry it at 70° C. for 48 hours, then calcinate the completely dried solid at 450° C. for 2 hours to obtain nano-titanium dioxide inorganic composite particles.

[0040] Step 3: Take nano-titanium dioxide inorganic composite particles and place them in a quartz test tube, add acetone solution of acrylamide, ultrasonically disperse for 8 minutes, add magnetons, and seal the test tube mouth after passing nitrogen gas for 5 minutes; wherein, the concentration of the acetone solution of acrylamide is 0.3 g / mL; the solid-liquid ratio of the nanometer titanium dioxide inorganic composite particle ...

Embodiment 2

[0044] Step 1: Take kaolin, then add TiO 2 Precursor, using ethylene glycol methyl ether as a dispersant, ultrasonically dispersed for 15 minutes; wherein, according to the ratio of solid to liquid, kaolin: titanium dioxide precursor: ethylene glycol methyl ether = 10.0g: 0.98g: 25.1mL.

[0045]Step 2: put the ultrasonicated liquid in step 1 into a closed blast drying oven and dry at 70°C for 48 hours, then calcinate the completely dried solid at 450°C for 2 hours to obtain nano-titanium dioxide inorganic composite particles.

[0046] Step 3: Get the nano-titanium dioxide inorganic composite particle and place it in a quartz test tube, add the acetone solution of acrylamide, ultrasonically disperse for 8 minutes, add magnetons, and feed nitrogen gas for 5 minutes to seal the test tube mouth; wherein, the concentration of the acetone solution of acrylamide is 0.3 g / mL; the solid-liquid ratio of the nano-titanium dioxide inorganic composite particles and the acetone solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com