Insertion core automatic glue injector of optical fiber movable connector and glue injection method thereof

A technology of movable connectors and glue injection machines, which is applied in the direction of coating and liquid coating on the surface, etc. It can solve the problems of low accuracy, large amount of connector ferrule usage, complicated operation, etc., and achieve glue dispensing The effect of moderate quantity, low equipment failure rate and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

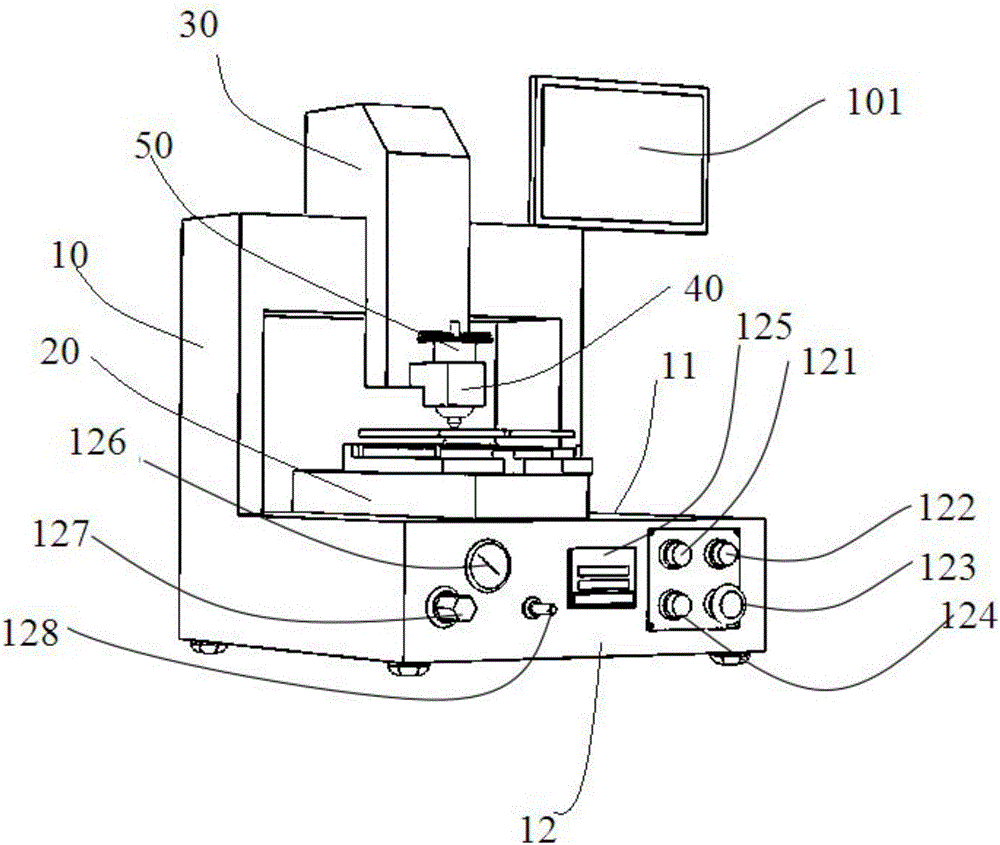

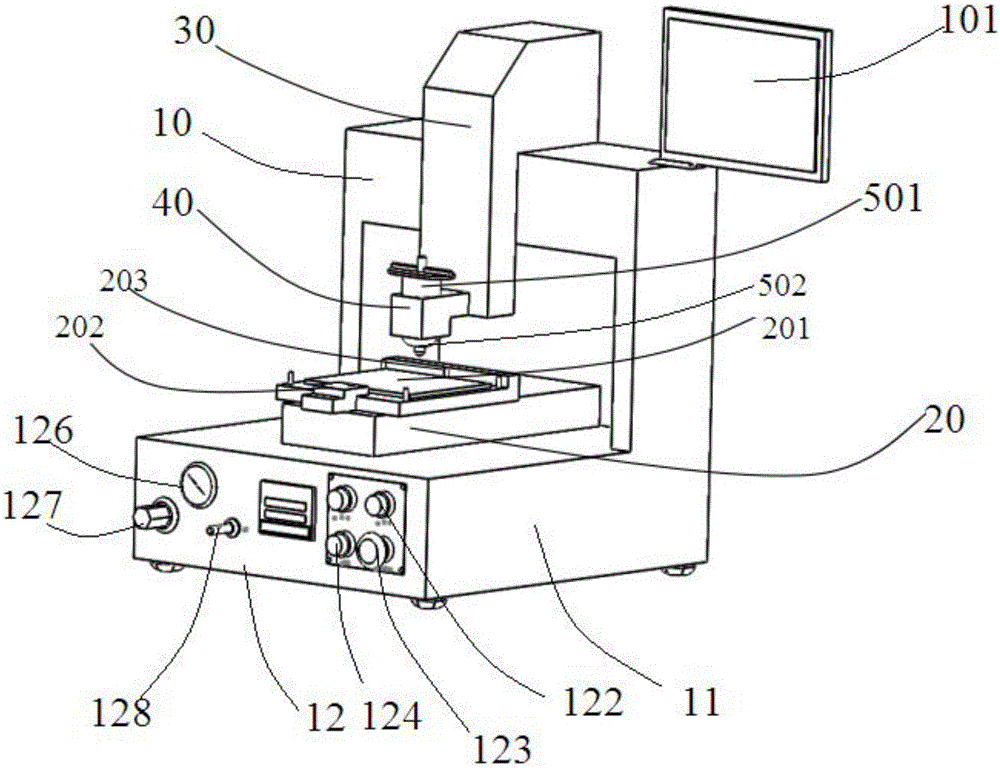

[0034] refer to Figure 1-4 As shown, this embodiment discloses an automatic glue injection machine for the ferrule of an optical fiber active connector. The automatic glue injection machine is mainly used in the glue injection process in the assembly process of the ferrule of the optical fiber active connector. It is an L-shaped machine platform, a control panel 12 is provided on one side of the machine platform, and a gantry cabinet body 10 is provided on the other side corresponding to the above-mentioned control panel 12, and the gantry cabinet body 10 stands on the top of the machine platform On the end face, the top end face of the above-mentioned machine platform is the working table surface 11 .

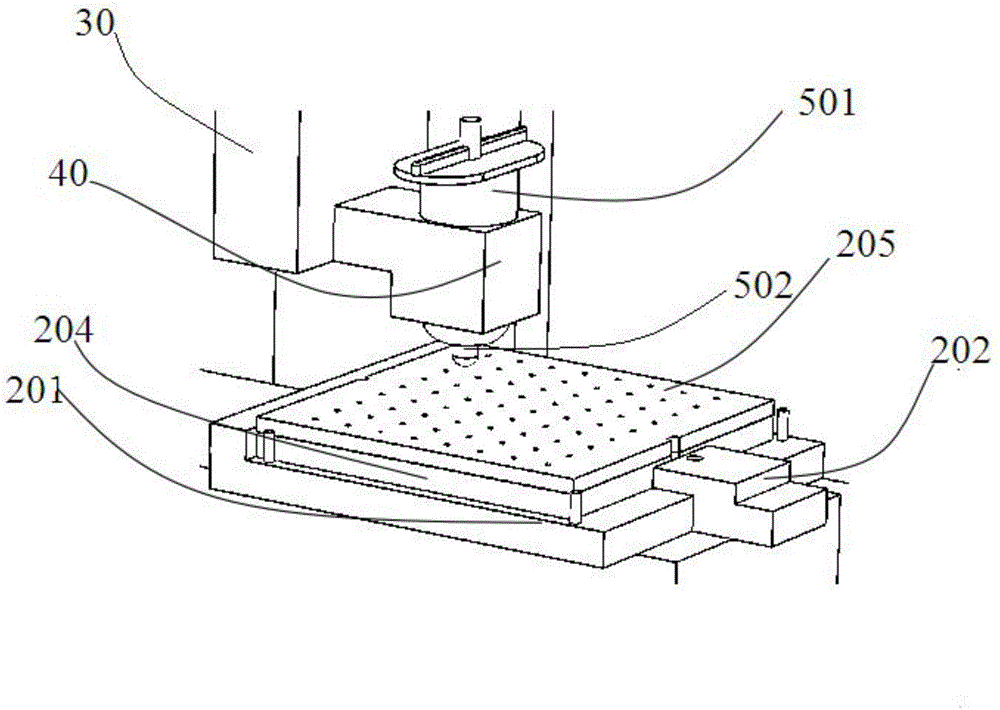

[0035] The above-mentioned worktable 11 is mainly used as a dispensing workbench, and a Y-axis motion mechanism 20 is provided on the above-mentioned worktable 11. The positioned array disk 204, the above-mentioned Y-axis movement mechanism 20 drives the above-mentioned arra...

Embodiment 2

[0045] A kind of glue injection method is disclosed in embodiment 2, this method is based on the glue injection device in embodiment 1, comprises the following steps:

[0046] Step 1: Fill the ferrule to be glued on the array disk, and then place the array disk on the workbench;

[0047] Step 2: Put the positioning array disk on the ferrule tail handle, and fix the array disk and the positioning array disk through the positioning piece and the locking piece;

[0048] Step 3: Turn on the start button, the equipment will start, and the equipment will run according to the set track according to the X, Y, and Z three-axis motion mechanism, until all products are injected with glue, and the equipment will automatically return to the initial position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com