Light rail assembled type elevated railway station for high intensity area

A prefabricated, high-intensity technology, applied in the field of elevated stations, can solve problems such as large volume, large impact on the surrounding environment, and large urban traffic pressure, and achieve good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

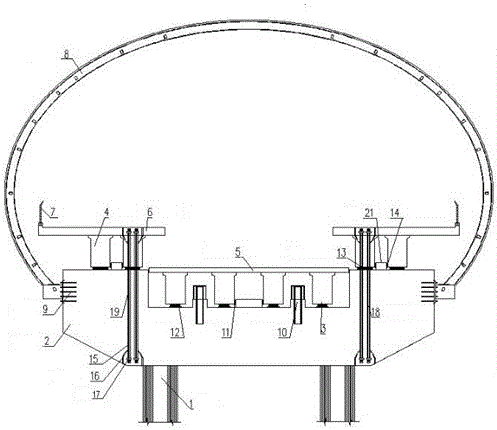

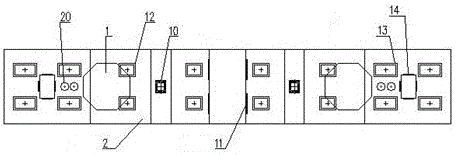

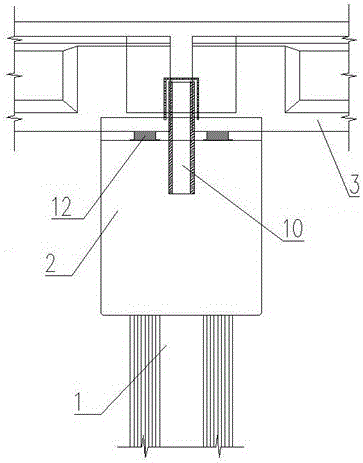

[0045] like Figure 1~6 As shown, a light rail assembled elevated station for high-intensity areas includes a pier column 1, and the pier column 1 is provided with a cover beam 2 that is half-shaped and cantilevered at both ends. The pier column 1, The cover beam 2 is Π-shaped in the transverse bridge direction, and the cantilevered end of the cover beam 2 is fixed to the steel structure roof 8 by the roof support 9, and the cover beam 2 is fixed by the lateral support 11 and the vertical support 12 There are a plurality of track beams 3, and the platform beam 4 is fixed on the cover beam 2 through the two-way limit support 13, and the platform beam 4 is connected laterally with the pad stone 21 at the top of the cover beam 2 through the laminated rubber support 14, A track plate 5 is fixed on the track beam 3 , and a platform plate 6 is fixed on the platform be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com