Mining dump truck frame with load level of 300 tons

A dump truck, frame technology, applied in vehicle parts, substructure, transportation and packaging, etc., can solve problems such as difficulty in meeting strength and rigidity, frame failure, fatigue cracks, etc., achieve smooth stress transition, prolong service life, The effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

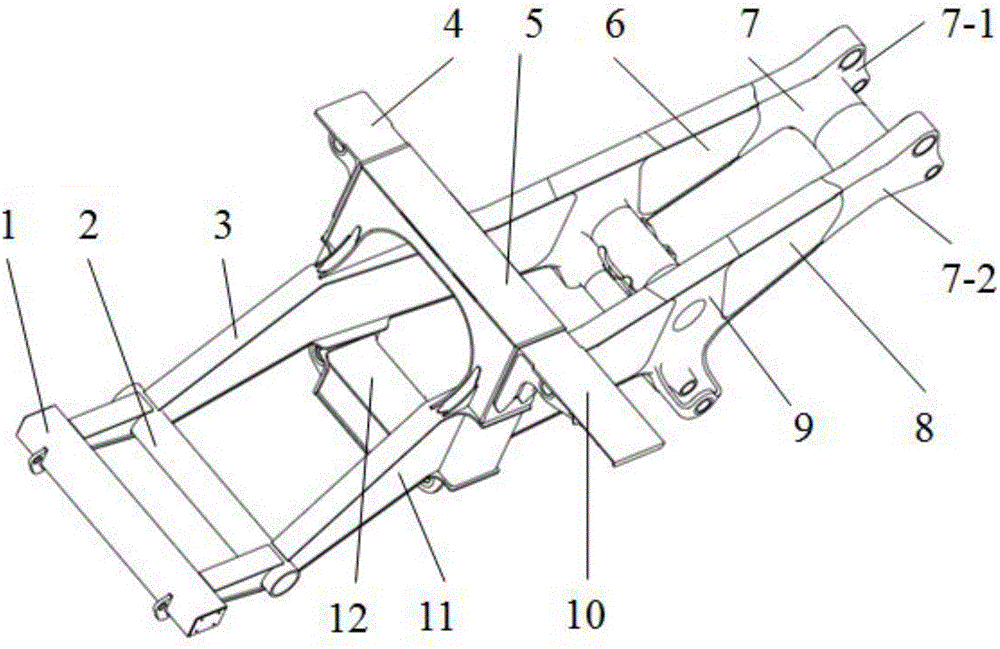

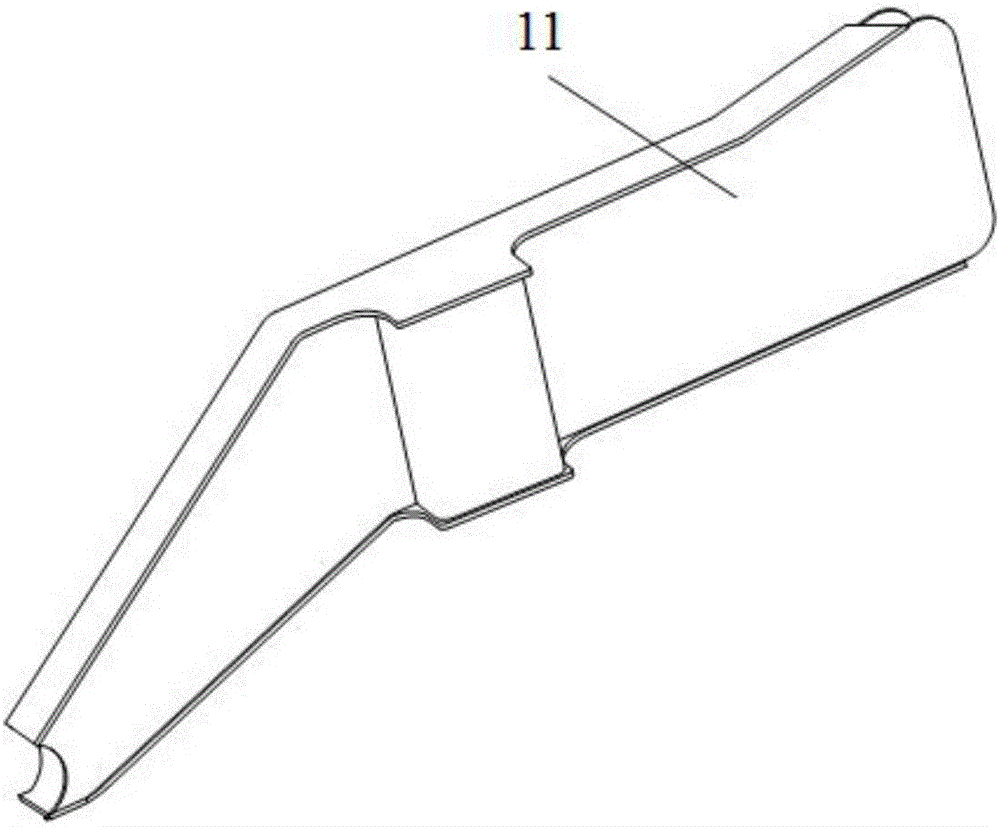

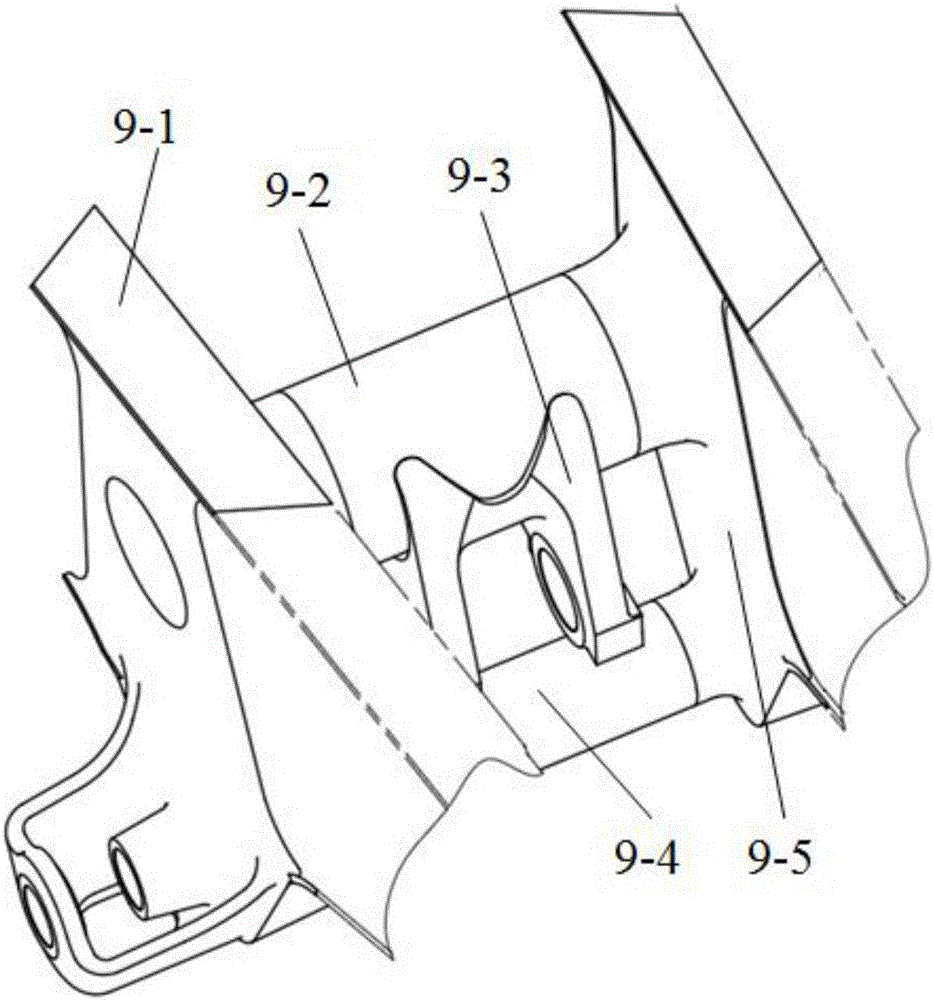

[0020] Such as Figure 1 to Figure 4 As shown, a frame of a 300-ton mining dump truck has a structure of six horizontal and two vertical structures as a whole, including a bumper assembly 1, a front beam 2, an upper gantry beam 5, a lower gantry beam 12, and a central lifting frame. Lifting component 9, tailstock component 7, left front suspension support 10, right front suspension support 4 and two sets of longitudinal beams on the left and right, the two sets of longitudinal beams on the left and right are parallel to the center plane of the vehicle and arranged symmetrically, the front is wide and the rear is narrow; the left longitudinal beam Including the left front longitudinal beam 11 and the left rear longitudinal beam 8, the right longitudinal beam includes the right front longitudinal beam 3 and the right rear longitudinal beam 6; the bumper assembly 1 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com