Mid-motor mounting structure for electric two-wheeled vehicle and two-wheeled vehicle comprising mid-motor mounting structure

An electric two-wheeled, mid-mounted motor technology, applied in the direction of motor vehicles, motorcycles, bicycles, etc., can solve the problems of difficulty in arranging high-power motors, motors occupying space at the main frame, and unfavorable service life, so as to avoid battery installation. The effect of moving up the position, simple installation and assembly, improved operability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

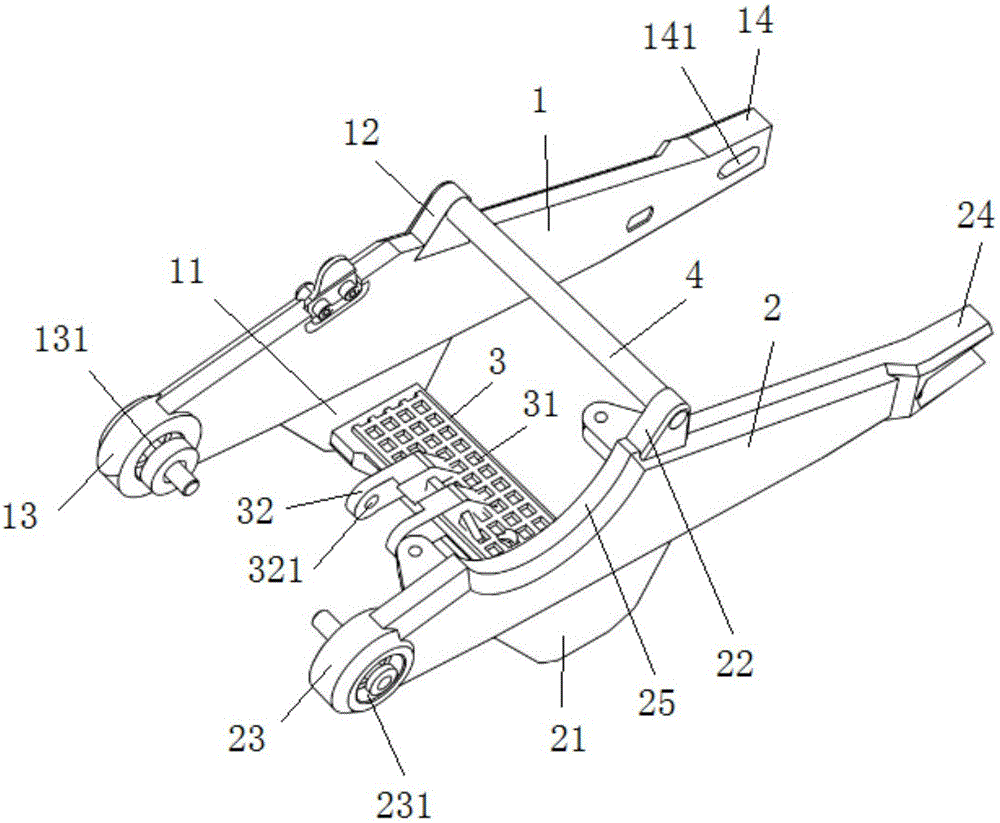

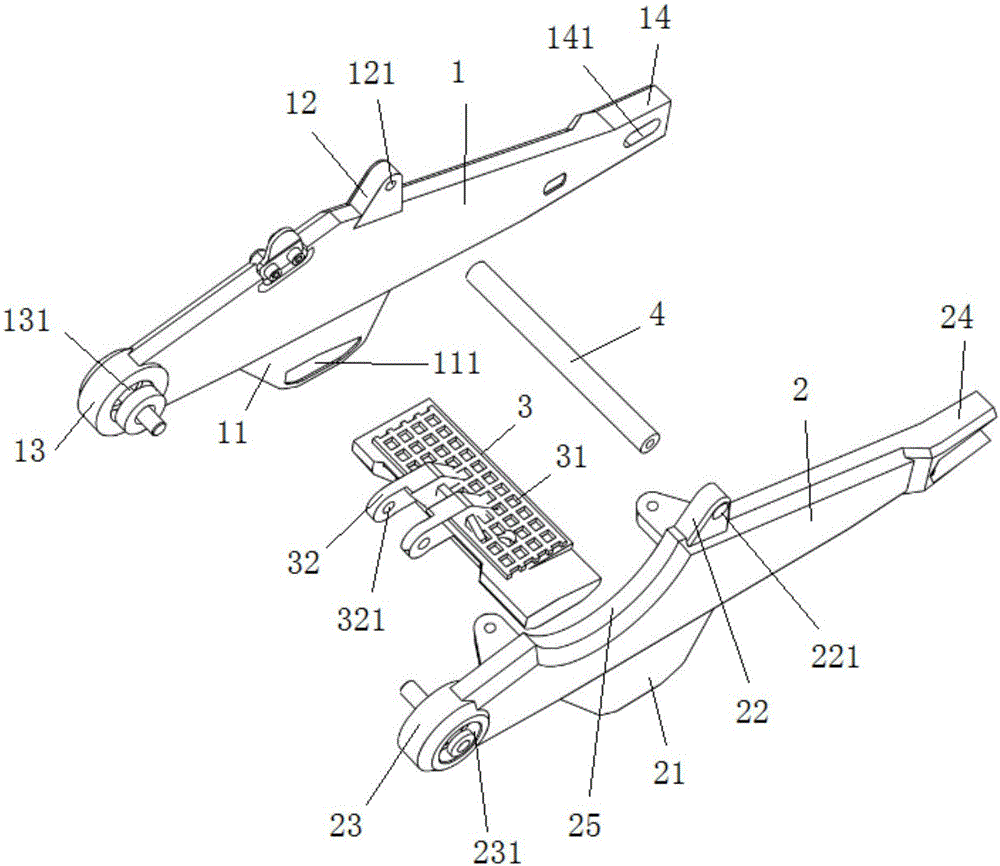

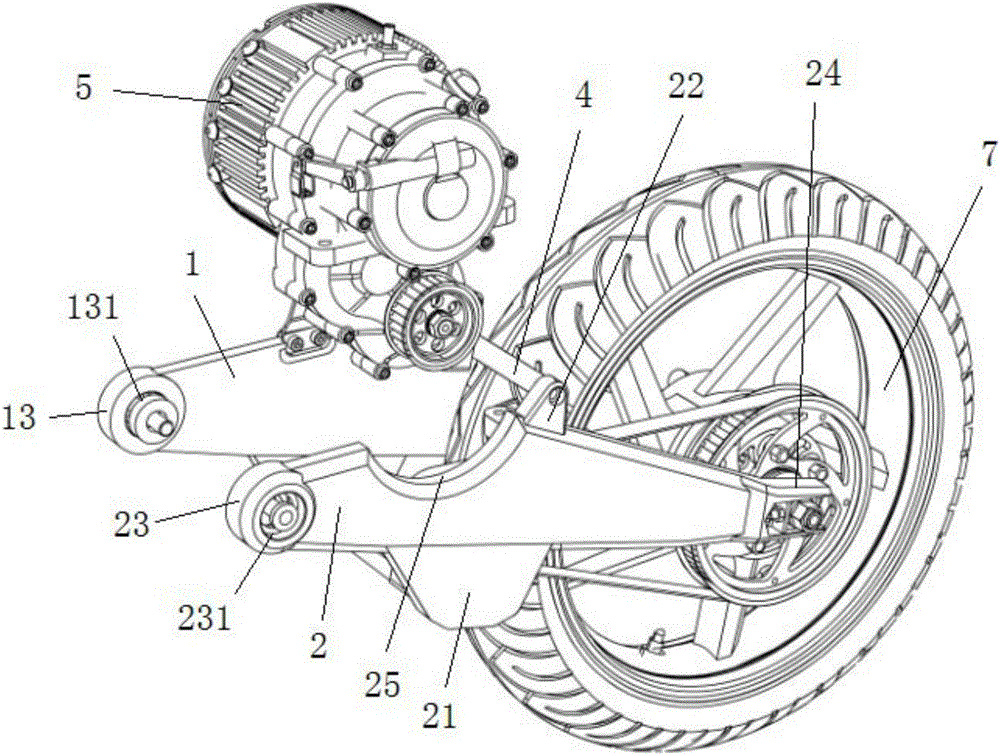

[0036] figure 1 It is a schematic diagram of the installation structure of the middle motor of an electric two-wheeled vehicle, figure 2 For the exploded view of the installation structure of the middle motor of the electric two-wheeler, please refer to figure 1 and figure 2 shown. Shown is a preferred embodiment of an electric two-wheel vehicle mid-mounted motor installation structure, including a left fork 1 and a right fork 2, the shape of the left fork 1 and the right fork 2 are the same.

[0037] Further, as a preferred embodiment, the installation structure of the middle motor of the electric two-wheeled vehicle includes a lower connecting body 3, and the two ends of the lower connecting body 3 are respectively connected to the lower end of the left flat fork 1 and the lower end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap