Suspension type six-degree-of-freedom micro-gravity environment simulating system

A technology of environment simulation and degree of freedom, which is applied to the simulation device of space navigation conditions, space navigation equipment, transportation and packaging, etc., can solve the problems of insufficient three-degree-of-freedom movement space, poor test results, and low compensation accuracy, etc., to achieve Improve system reliability, reduce complexity, and expand the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

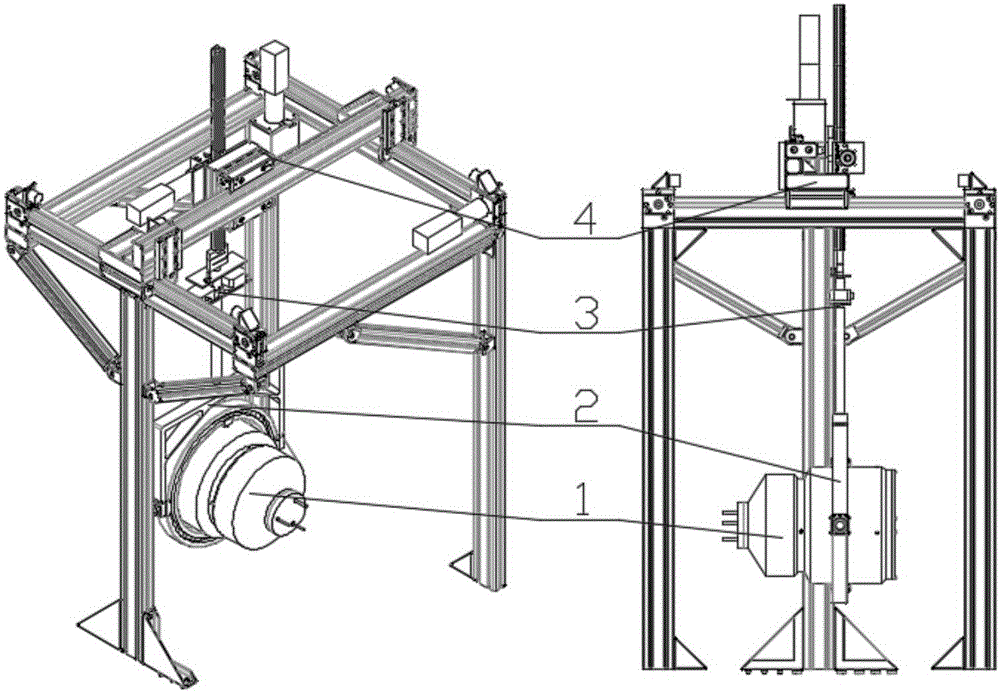

[0035] combine figure 1 , a suspended six-degree-of-freedom microgravity environment simulation system of the present invention includes a simulated spacecraft 1 , an attitude follow-up and fixation unit 2 , a buffer and sensor installation unit 3 and a space three-dimensional follow-up unit 4 . The simulated spacecraft 1 is connected to the buffer and sensor installation unit 3 through the attitude follow-up and fixed unit 2 , and the buffer and sensor installation unit 3 is connected to the space three-dimensional follow-up unit 4 .

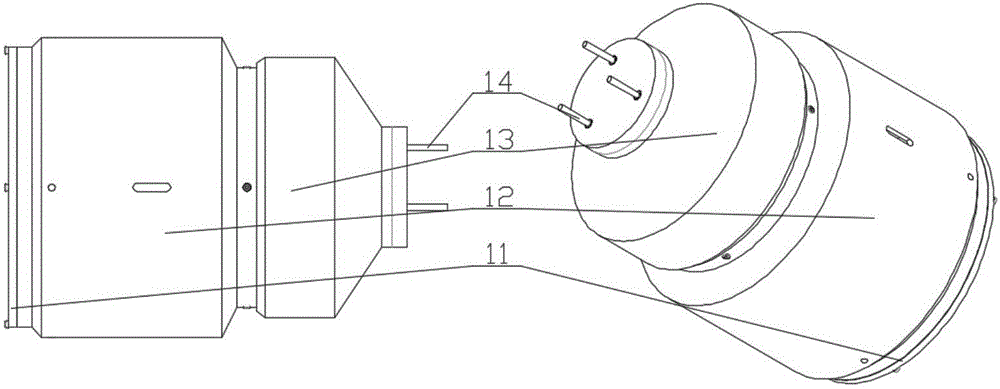

[0036] combine figure 2 , the simulated spacecraft 1 includes a spacecraft base plate 11, a spacecraft main body 12, a spacecraft docking end 13 and a docking rod 14, the spacecraft base plate 1 and the spacecraft docking end 13 are installed at the two ends of the spacecraft main body 12, and the docking rod 14 is installed On the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com