Method for recycling phosgene in tail gas produced through thermo-optical reaction for synthesis of 3,5-dichlorophenyl isocyanate

A technology of dichlorophenylisocyanate and phosgene, which is applied in the preparation of isocyanic acid derivatives, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of difficult leakage, affecting product quality and yield, and potential accidents problem, to achieve the effect of reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

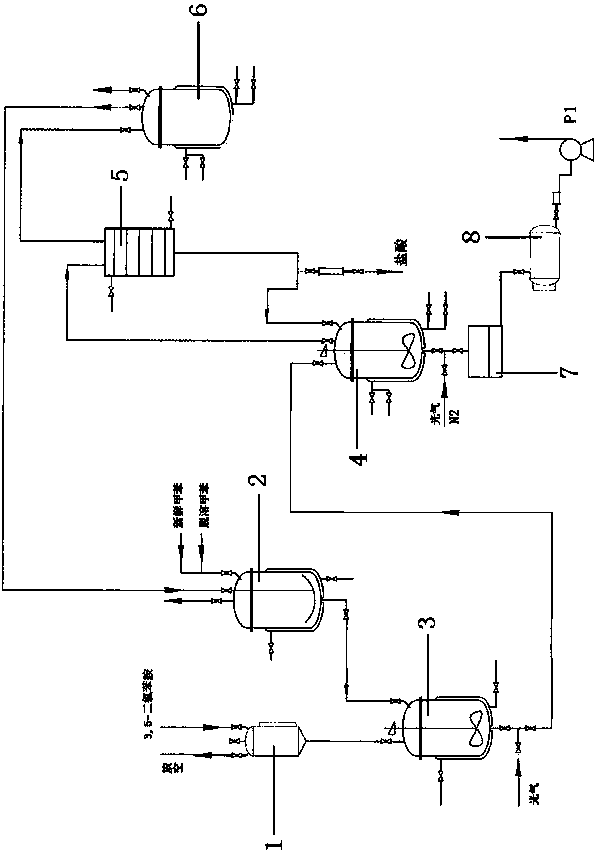

[0023] Such as figure 1 Shown, a kind of synthetic 3,5-dichlorophenyl isocyanate thermo-optic reaction tail gas recycles the method for phosgene in tail gas, carries out as follows:

[0024] Step 1) Put the phosgene-toluene solution in the tail gas cooling pot 2 into the cold light kettle 3, then add the 3,5-dichloroaniline toluene solution in the dropping tank 1 into the cold light kettle 3 dropwise, and stir At the same time, store phosgene I from the bottom of the luminescent kettle 3 and stir evenly to obtain a mixed solution; the temperature of the tail gas cooling pot 2 is controlled at -5~0°C; the temperature of the luminescent kettle 3 is controlled at 0~5°C;

[0025] In the described phosgene-toluene solution, its phosgene consumption is 200m³, and the toluene consumption is 3500L;

[0026] The amount of 3,5-dichloroaniline is 800kg, and the amount of phosgene I is 120m³;

[0027] Step 2) Transfer the mixed liquid to the thermo-optical kettle 4, and stir to raise th...

Embodiment 2

[0032] Synthesis: Dissolve 800kg of 3,5-dichloroaniline in 1850L of toluene, then add 3500L of toluene to the cold light kettle 3, store luminescence of 200 m³, then add the aniline toluene liquid dropwise and let the light pass through 120m³, and discharge the material into the thermolight kettle 4. Through heat and light 120m³, phosgene has a total mass of 440m³ and a mass of 1496kg.

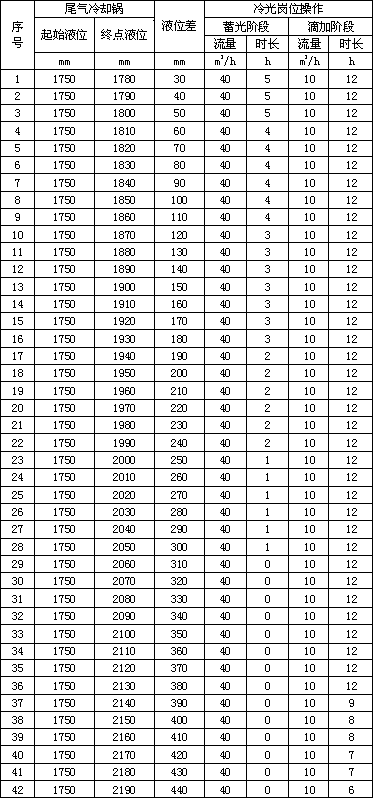

[0033] 1. Put the phosgene toluene liquid absorbed in the tail gas cooling pot into the cold light kettle, add 3,5-dichloroaniline and toluene mixture dropwise under stirring, store the cold light and drop the light passing time according to the liquid level of the tail cold pot - Lighting schedule, see Table 1; transfer materials from cold light kettle 3 to hot light kettle 4.

[0034] 2. After the cold light kettle 3 is fed into the hot light kettle 4. Open the gas valve on the thermo-optic kettle 4, the return valve, and confirm that the brine valve of the thermo-optic condenser 5 is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com