Shock-resistant polypropylene composite material with high fluidity and high rigidity

A technology of impact-resistant polypropylene and composite materials, which is applied in the field of polypropylene composite materials, can solve the problems of polypropylene resin fluidity and product mechanical properties that cannot meet actual needs, and achieve reduced material odor, good compatibility, and difficulty in agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

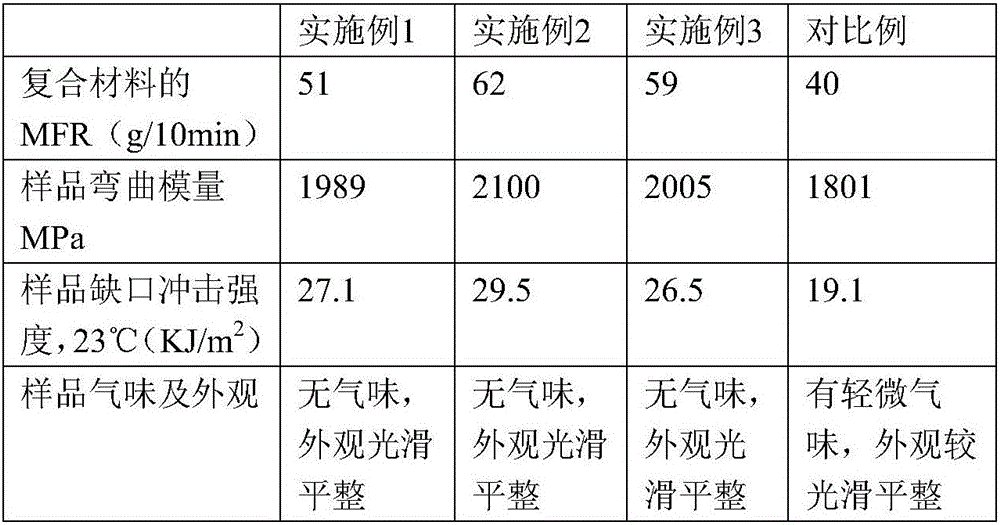

Examples

Embodiment 1

[0019] (1) Prepare porous silica microspheres first: place porous polystyrene polymer microspheres in ethanol and ultrasonically homogenize, then add ammonia water, methyl orthosilicate or ethyl orthosilicate ethanol solution in turn, and stir to react After 22 hours, wash, dry, and finally place in a muffle furnace for calcination to obtain porous silica microspheres;

[0020] (2) Prepare the silica filler modified by silane coupling agent: mix the silane coupling agent and silica filler (porous silica microspheres and nano-scale silica powder) evenly, and stir at 100°C, After reacting for 6 hours, centrifuge, filter, wash, and dry to obtain a silica filler modified with a silane coupling agent;

[0021] (3) Take a total of 15 parts of the silica filler modified by the silane coupling agent prepared above, 100 parts of polypropylene, 5 parts of organic nucleating agent, and 10 parts of POE elastomer, and dry the above raw materials in a high-speed mixer Mix for 10 minutes, t...

Embodiment 2

[0024] (1) Prepare porous silica microspheres first: place porous polystyrene polymer microspheres in ethanol and ultrasonically homogenize, then add ammonia water, methyl orthosilicate or ethyl orthosilicate ethanol solution in turn, and stir to react After 22 hours, wash, dry, and finally place in a muffle furnace for calcination to obtain porous silica microspheres;

[0025] (2) Prepare the silica filler modified by silane coupling agent: mix the silane coupling agent and silica filler (porous silica microspheres and nano-scale silica powder) evenly, and stir at 100°C, After reacting for 6 hours, centrifuge, filter, wash, and dry to obtain a silica filler modified with a silane coupling agent;

[0026] (3) Take 20 parts of the silica filler modified by the silane coupling agent prepared above, mix with 100 parts of polypropylene, 2 parts of organic nucleating agent, and 15 parts of POE elastomer, and melt blend to obtain a polypropylene composite material , preparation pro...

Embodiment 3

[0029] (1) Prepare porous silica microspheres first: place porous polystyrene polymer microspheres in ethanol and ultrasonically homogenize, then add ammonia water, methyl orthosilicate or ethyl orthosilicate ethanol solution in turn, and stir to react After 22 hours, wash, dry, and finally place in a muffle furnace for calcination to obtain porous silica microspheres;

[0030] (2) Prepare the silica filler modified by silane coupling agent: mix the silane coupling agent and silica filler (porous silica microspheres and nano-scale silica powder) evenly, and stir at 100°C, After reacting for 6 hours, centrifuge, filter, wash, and dry to obtain a silica filler modified with a silane coupling agent;

[0031] (3) Take 10 parts of the silica filler modified by the silane coupling agent prepared above, mix with 100 parts of polypropylene, 1 part of organic nucleating agent, and 10 parts of POE elastomer, and melt blend to obtain a polypropylene composite material , preparation proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com