A kind of water-based metal anti-corrosion material and preparation method thereof

A metal anti-corrosion, water-based technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of insignificant and few, and achieve the effect of reducing pollution, good compatibility and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with examples.

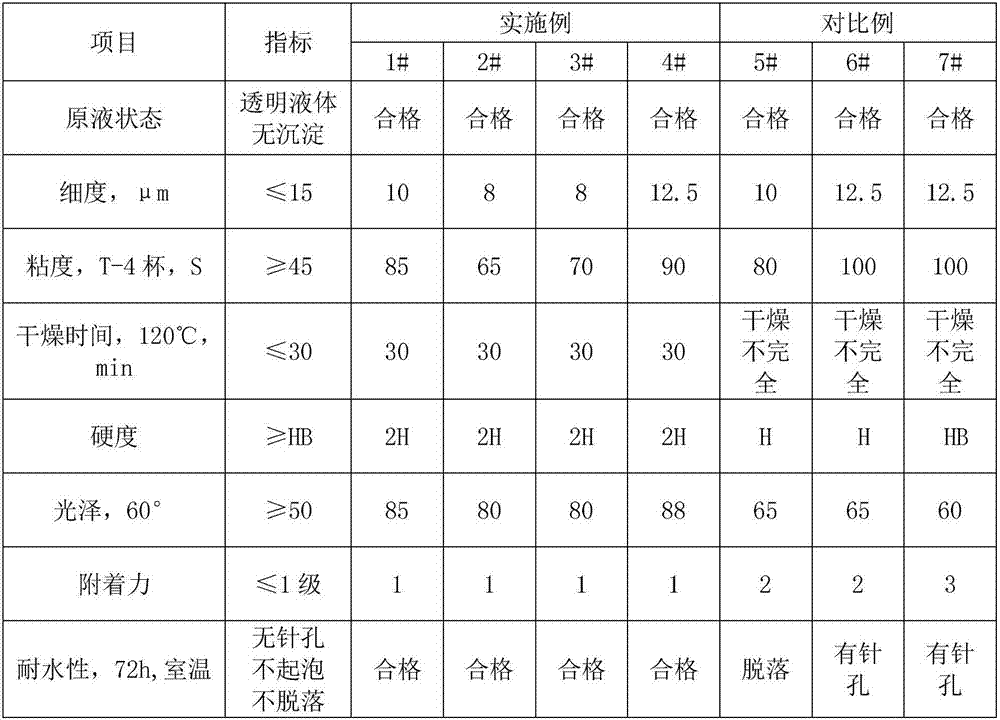

[0023] A kind of water-based metal anticorrosion material of the present invention is composed of the components in Table 1 in parts by weight:

[0024] Table 1

[0025]

[0026] The epoxy soybean oil modified alkyd resin used in embodiment 1-4# and comparative example 1-3# is prepared according to the following steps:

[0027] (1) Under the protection of dry nitrogen gas, add 20-25 parts of trimethylolpropane, 20-25 parts of 1,2-propylene glycol, and 10-15 parts of maleic anhydride to the In a four-neck flask, stir and mix evenly;

[0028] (2) Add 0.1-0.2 parts of lithium hydroxide and 0.1-0.5 parts of antioxidant 1010 to step (1), slowly raise the temperature to 190-200°C, and react for 2-4 hours;

[0029] (3) Add 10-15 parts of epoxidized soybean oil to rapidly ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com