A ground color marking device for cables and its laying method

A marking device and marking technology, applied to display devices, illuminated marks, coatings, etc., can solve the problems of ground marking wear or aging, loss of recognition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

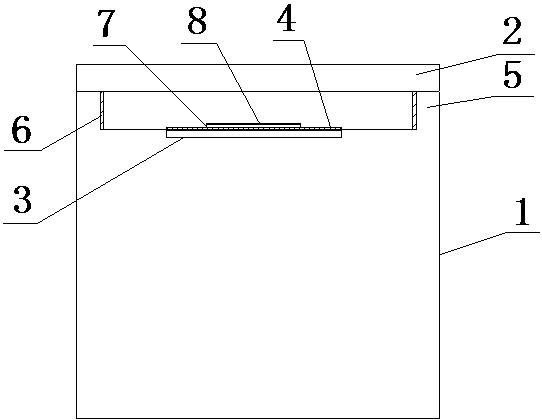

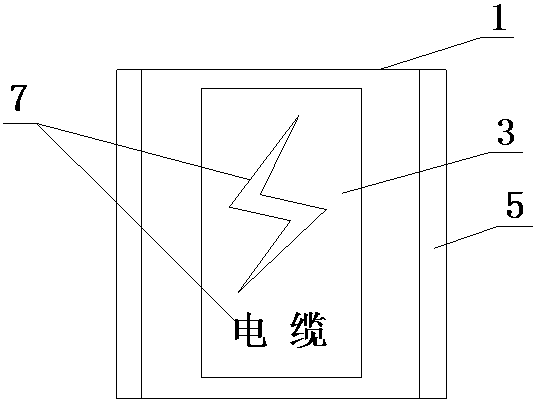

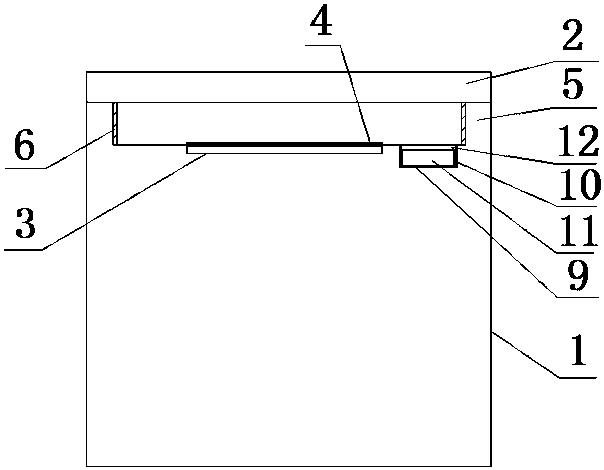

[0035] refer to Figure 1~2 , a ground color marking device for cables, comprising a marking base 1 corresponding to the cable, and a transparent tempered glass 2 laid on the upper part of the marking base 1, the upper surface of the marking base 1 is embossed with a marking part 3, the The surface of the marking part 3 is sprayed with luminous paint I4, and the periphery of the upper surface of the marking base 1 protrudes upwards to form a flange 5, and the flange 5 is provided with a reflective paint 6 toward the side of the marking base 1, so The lower surface of the transparent tempered glass 2 is in sealing connection with the top of the flange 5 .

[0036] The luminous paint I4 is made of the following raw materials in parts by weight: 110 parts of WT800 silicone resin, 6 parts of butyl ester, 8 parts of xylene, 1.0 parts of wetting agent, 2 parts of dispersing agent, 25 parts of pigment, and 4 parts of talcum powder , 6.5 parts of organic bentonite, 3 parts of glass f...

Embodiment 2

[0043] refer to Figure 1~2 , the ground color marking device of the cable described in this embodiment is different from Embodiment 1 in that:

[0044] The luminous paint I4 is made of the following raw materials in parts by weight: 100 parts of WT800 silicone resin, 5 parts of butyl ester, 7 parts of xylene, 0.5 parts of wetting agent, 1 part of dispersing agent, 20 parts of pigment, and 3 parts of talcum powder , 5 parts of organic bentonite, 2 parts of glass fiber, 0.8 parts of leveling agent, and 3 parts of luminous powder.

[0045] The pigment is iron red, and the luminous powder is red luminous powder; the red luminous powder is composed of the following materials in parts by weight: 55 parts of barium sulfate, 40 parts of magnesium sulfate, 2 parts of lithium phosphate, and 3 parts of copper nitrate.

[0046] The leveling agent is polydimethylsiloxane.

[0047] The particle size of the luminous powder is 400 mesh.

Embodiment 3

[0049] refer to Figure 1~2 , the ground color marking device of the cable described in this embodiment is different from Embodiment 1 in that:

[0050] The luminous paint I4 is made of the following raw materials in parts by weight: 120 parts of WT800 silicone resin, 8 parts of butyl ester, 11 parts of xylene, 1.5 parts of wetting agent, 3 parts of dispersing agent, 30 parts of pigment, and 6 parts of talcum powder , 10 parts of organic bentonite, 4 parts of glass fiber, 1.6 parts of leveling agent, 5 parts of luminous powder.

[0051] The pigment is cobalt green and the glow in the dark is green glow in the dark. The green luminous powder is composed of the following materials in parts by weight: 55 parts of calcium sulfide, 1 part of potassium sulfide, 10 parts of sodium sulfide, 12 parts of barium nitrate, and 13 parts of indium nitrate.

[0052] The leveling agent is polydimethylsiloxane.

[0053] The particle size of the luminous powder is 1500 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com