Method for preparing high-brightness red light long afterglow luminous material

A luminous material and red light technology, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of short fluorescence intensity and afterglow time, and achieve the effects of long afterglow time, high fluorescence brightness and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

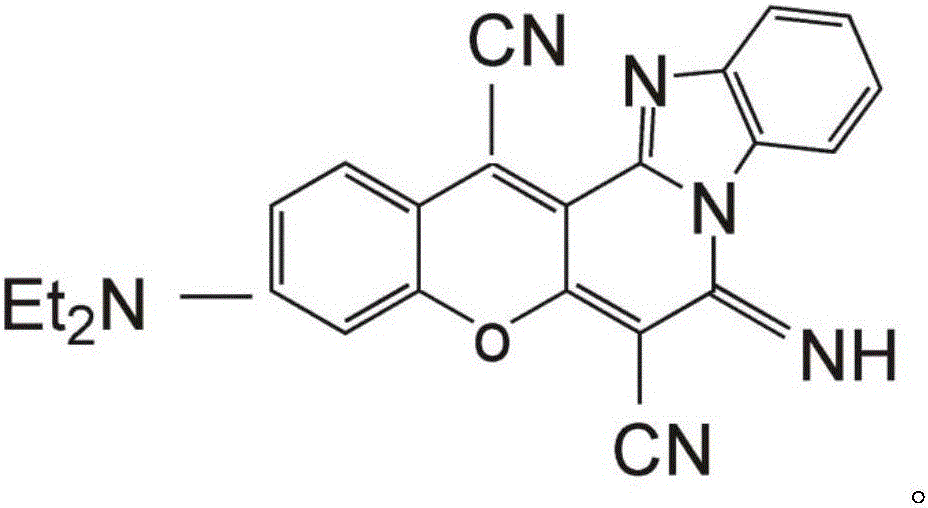

[0019] Weigh 0.3g red fluorescent dye and dissolve it in 104.83g deionized water; weigh 34.67g tetraethyl orthosilicate (TEOS) and dissolve it in 230g dehydrated ethanol; then add the mixed solution of TEOS and dehydrated ethanol to the above deionized water In ionized water, adjust the pH value of the mixed solution to 2 with nitric acid, and magnetically stir for 30 minutes at 60°C and a stirring speed of 400 rpm to allow TEOS to fully hydrolyze and form a uniform and transparent sol;

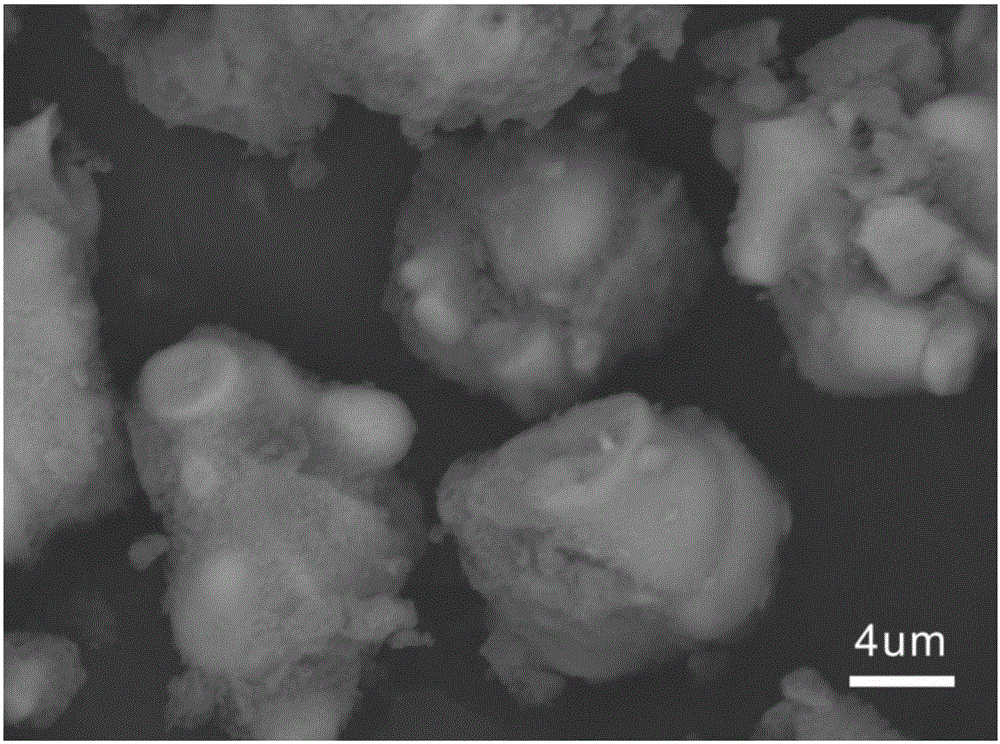

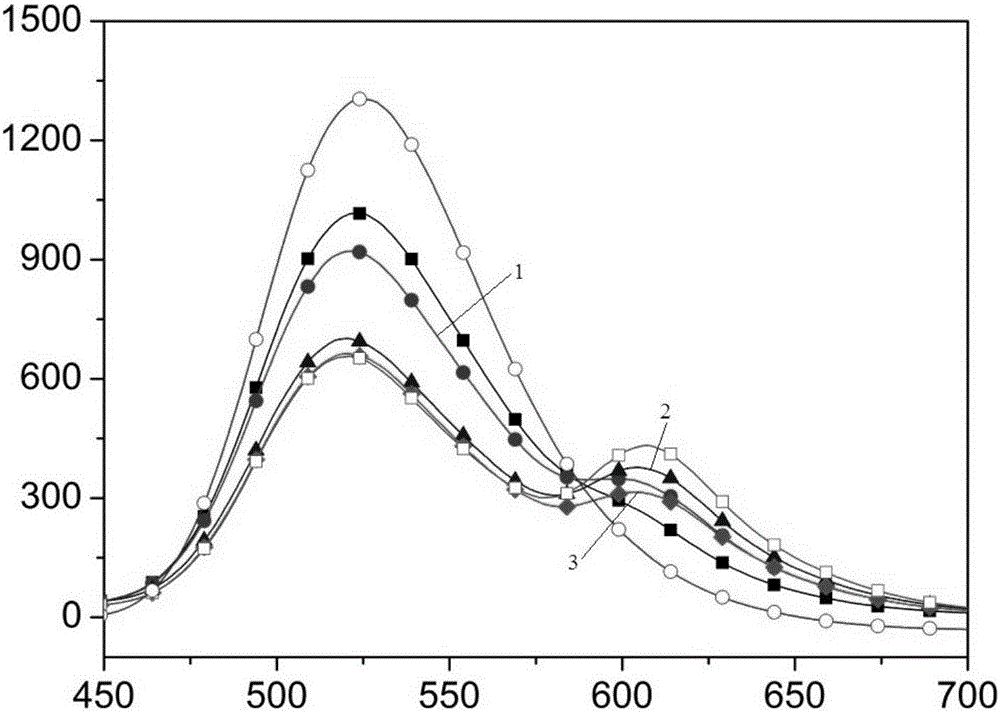

[0020] Slowly pour 100g of SAOED, a yellow-green light long afterglow luminous material, into the above-mentioned sol solution, continue heating and stirring until SAOED begins to expand and loosen, forming a flocculent gel; place the flocculent gel of SAOED in a closed environment at room temperature, and age After 20 hours, put it into a constant temperature blast drying oven, and dry it at 60°C for 24 hours; after the gel is completely dry, put it in a tubular high-temperature calciner, cal...

Embodiment 2

[0022] Weigh 0.5g red fluorescent dye and dissolve it in 157.28g deionized water; weigh 52g tetraethyl orthosilicate (TEOS), dissolve it in 345g absolute ethanol; then add the mixed solution of TEOS and absolute ethanol to the above deionized water In ionized water, adjust the pH value of the mixed solution to 3 with nitric acid, and magnetically stir for 25 minutes at 70°C and a stirring speed of 460 rpm to allow TEOS to be fully hydrolyzed to form a uniform and transparent sol;

[0023] Slowly pour 100g of the yellow-green long-lasting luminous material SAOED into the above-mentioned sol solution, and continue heating and stirring until the SAOED begins to expand and loosen to form a flocculent gel; place the flocculent gel of SAOED in a closed environment at room temperature, After melting for 24 hours, put it into a constant temperature blast drying oven, and dry it at 70°C for 20 hours; after the gel is completely dry, put it in a tube-type high-temperature calciner, calci...

Embodiment 3

[0025] Weigh 0.7g red fluorescent dye and dissolve it in 209.66g deionized water; weigh 69.34g tetraethyl orthosilicate (TEOS) and dissolve it in 460g dehydrated ethanol; then add the mixed solution of TEOS and dehydrated ethanol to the above deionized water In deionized water, use nitric acid HNO 3 Adjust the pH value of the mixed solution to 3, and magnetically stir for 20 minutes at 70°C and a stirring speed of 420 rpm to allow TEOS to fully hydrolyze and form a uniform and transparent sol;

[0026] Slowly pour 100g of the yellow-green long-lasting luminous material SAOED into the above-mentioned sol solution, and continue heating and stirring until the SAOED begins to expand and loosen to form a flocculent gel; place the flocculent gel of SAOED in a closed environment at room temperature, After melting for 24 hours, put it into a constant temperature blast drying oven, and dry it at 80°C for 20 hours; after the gel is completely dry, put it in a tubular high-temperature ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com