A steel truss girder walking type jacking device

A jacking device and walking-type technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low efficiency and waste of materials, achieve adjustable synchronization error, reduce jacking time, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

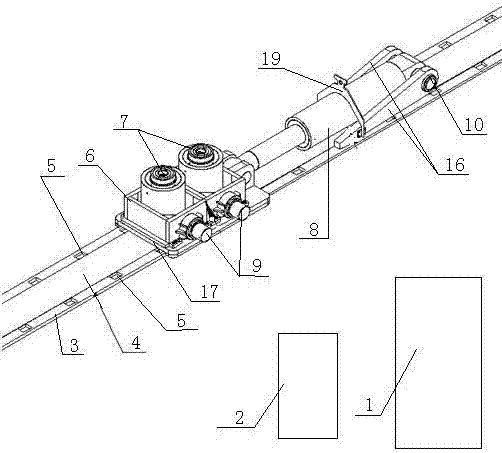

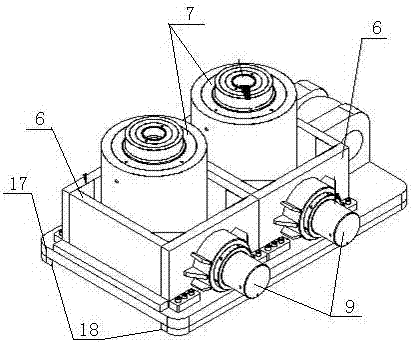

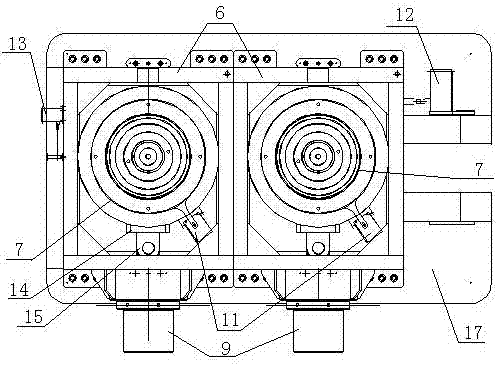

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 A steel truss girder walking type jacking device shown includes slide rails and multiple sets of push devices on the slide rails, a hydraulic pump station 1, and a PLC main control machine 2. The slide rails include a bottom plate 3 and a slide plate 4, Both sides of the bottom plate 3 are provided with a plurality of evenly distributed rectangular slots 5, and the pushing device includes a sliding box 6, a jacking cylinder 7, a horizontal pushing cylinder 8 and a correction cylinder 9, and the sliding box 6 can slide on the slide rail. The piston of the horizontal push cylinder 8 is connected with one end of the sliding box 6 through a horizontal push pin, and the bottom of the cylinder body of the horizontal push cylinder 8 is connected with The pawls 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com