Dismounting method for metro section segments intruding into tunnel gauge

A segment removal and segment technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of poor soil quality at the top of the buried depth of the tunnel, narrow working space, and easy collapse, etc., to achieve fast demolition and safety accidents The effect of low efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

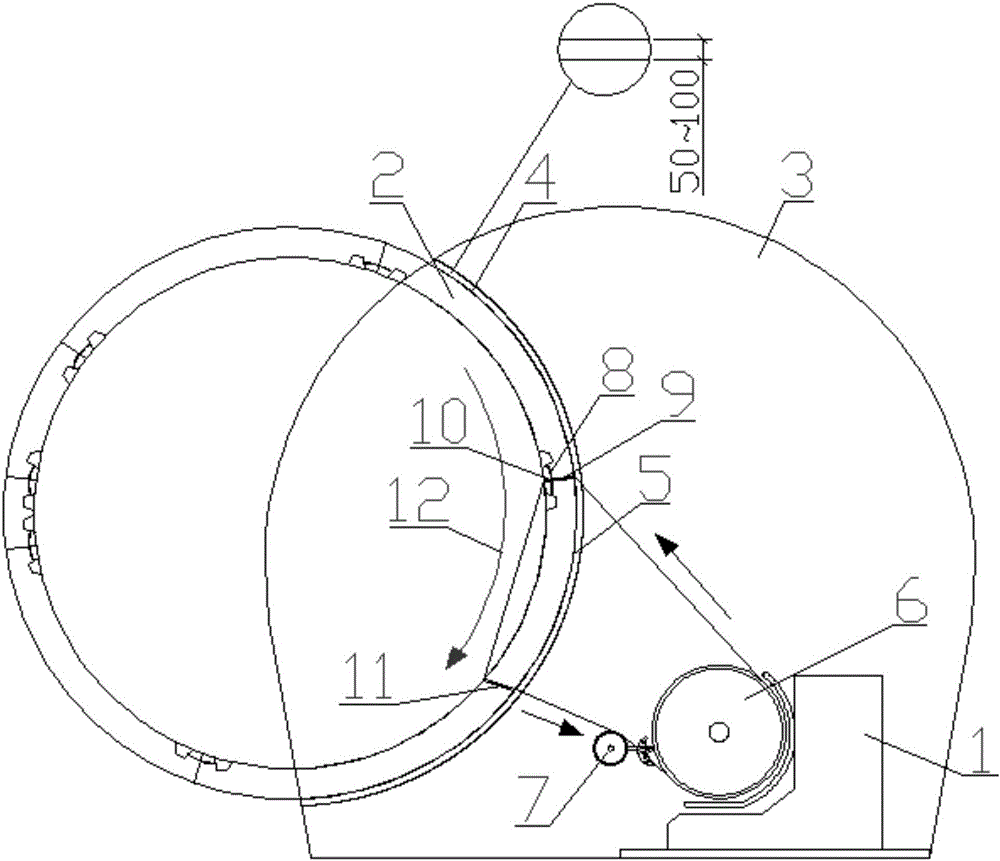

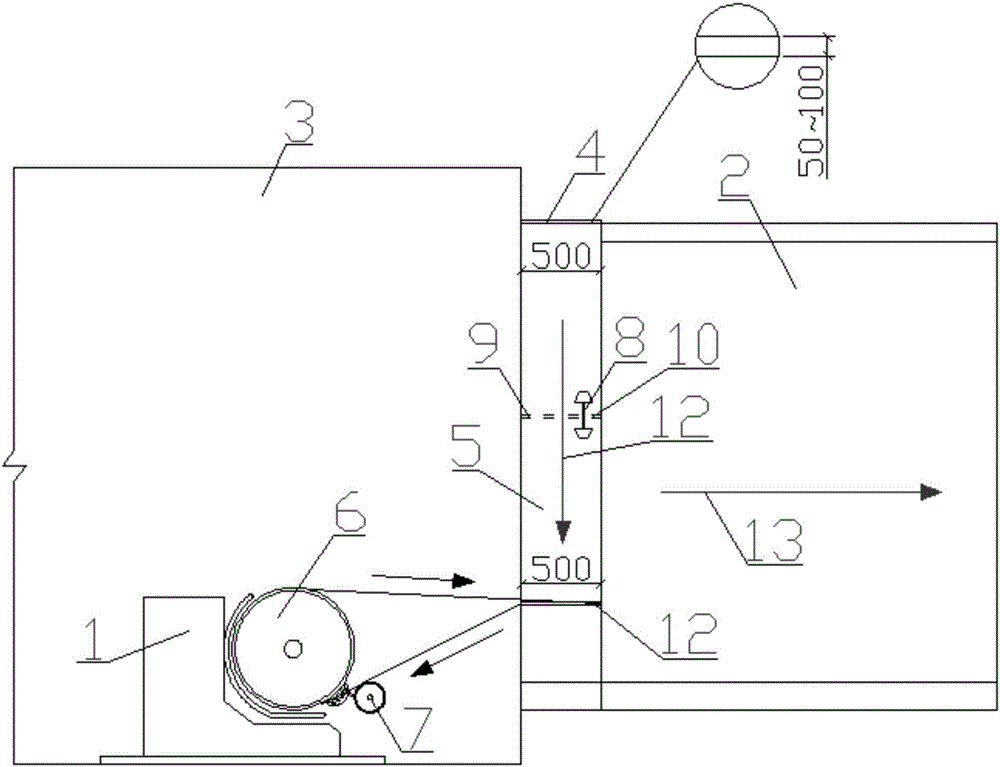

[0019] 1. Hollow out the back of the segment, and the hollowing depth is about 500mm, so that a cavity gap of 50mm-100mm is formed between the segment and the surrounding rock.

[0020] 2. Remove a segment ring bolt, and drill a hole (the first hole) along the longitudinal seam with a water mill drill. The hole position is 500 mm away from the segment removal direction (longitudinal direction), the hole diameter is 30 mm to 50 mm, and the hole depth is greater than the segment thickness. Drill a hole (the second hole) along the same circumferential section of the whole segment as the first hole, and the hole position is 500mm away from the direction in which the segment is removed.

[0021] 3. The first hole and the second hole are inserted into the cutting wire saw, and the wire saw is wound on the driving wheel and the auxiliary wheel. Start the wire saw cutting machine, and the wire saw runs around the cutting surface to grind and cut the pipe piece to complete the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com