Overlying strata abscission layer grouting technology and device

A technology of overlying strata separation and grouting, which is applied in the direction of safety devices, fillings, drilling equipment and methods, etc., can solve problems such as ecological environmental hazards, polluted land resources, and surface subsidence, so as to ensure compressive strength, High filling efficiency and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

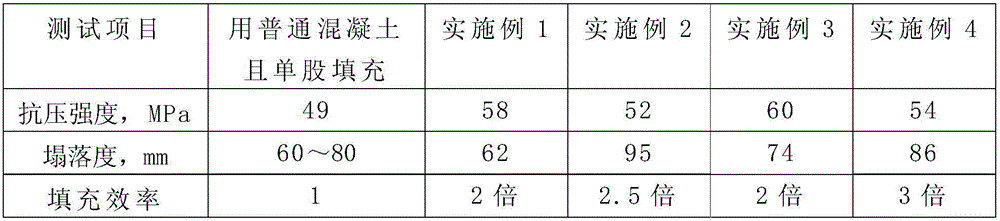

Embodiment 1

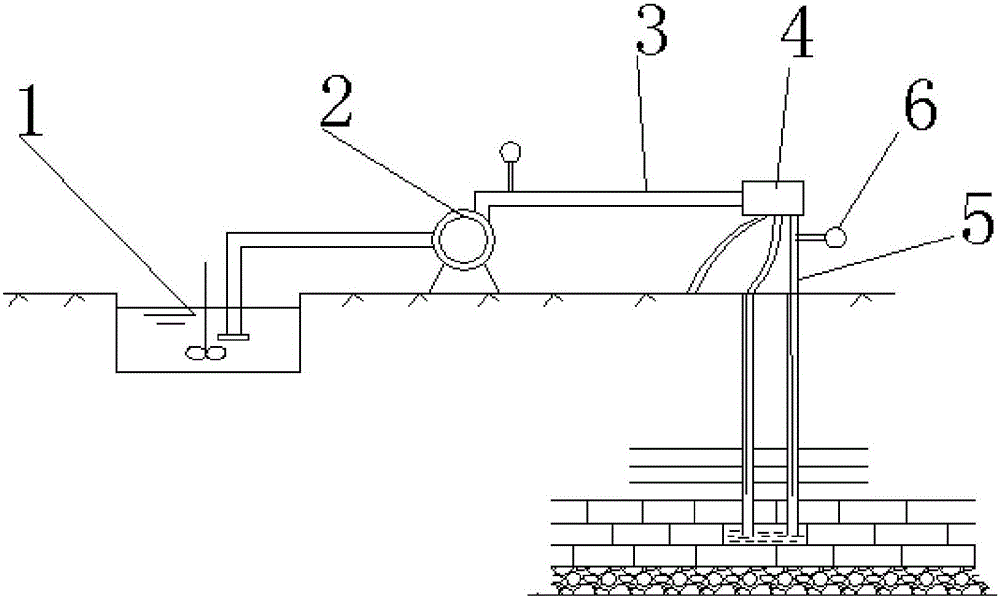

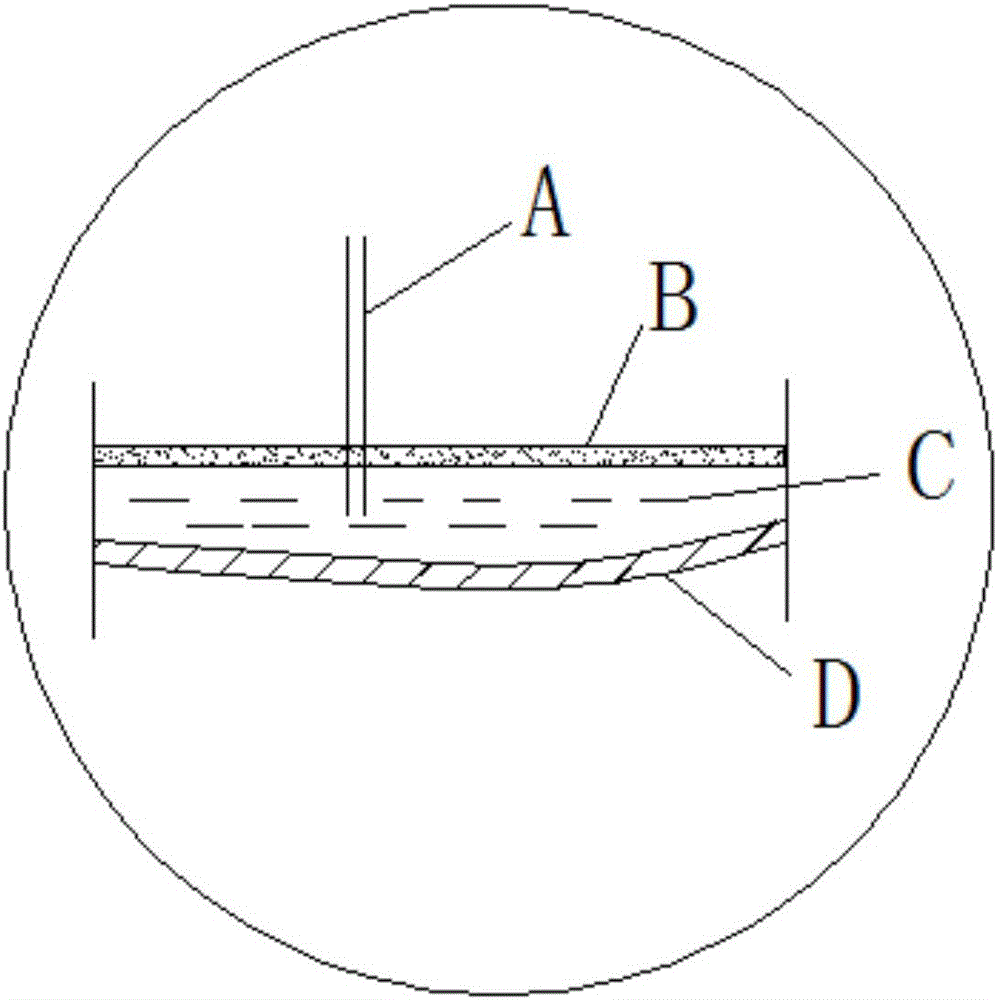

[0033] Such as figure 1 and figure 2 As shown, a grouting device for overburden separation layer includes a slurry pool 1, a pumping structure 2, a pipeline 3, a flow diversion device 4, a flow diversion pipeline 5 and a pressure gauge 6, wherein the inlet of the pumping structure 2 is connected to the slurry pool 1, and the outlet The diversion device 4 is connected through the pipeline 3, the outlet of the diversion device 4 is connected to the diversion pipeline 5, and a pressure gauge 6 is installed on each diversion pipeline 5 to monitor the pressure, and the diversion pipeline 5 extends into the borehole A, so that the slurry is injected into the separation layer space After being solidified into slurry C, it becomes a filling body with a certain strength. There is support between the upper rock layer B and the lower rock layer D, and the overlying rock is not easy to move, deform, break or even collapse.

[0034] An overlying rock separation layer grouting process, th...

Embodiment 2

[0047] A layer-separated grouting device for overlying rock, comprising a grout pool 1, a pumping structure 2, a pipeline 3, a diversion device 4, a diversion pipeline 5, and a pressure gauge 6, wherein the inlet of the pumping structure 2 is connected to the grout pool 1, and the outlet passes through the pipeline 3 Connect the diversion device 4, the outlet of the diversion device 4 is connected to the diversion pipe 5, and each diversion pipe 5 is equipped with a pressure gauge 6 to monitor the pressure, and the diversion pipe 5 extends into the borehole A, so that the slurry is injected into the separated layer space, and the slurry is solidified into a slurry After filling body C, it becomes a filling body with a certain strength. There is support between the upper rock layer B and the lower rock layer D, and the overlying rock is not easy to move, deform, break or even collapse. For the convenience of filling and better effect, the front section of the distribution pipeli...

Embodiment 3

[0061] A kind of overlying rock separation layer grouting process, different from embodiment 1: in step a, the distance between every two adjacent boreholes is 0.6m; in step b, the mass ratio of each component is 1:0.62:0.43: 0.16:0.005, the rest of the operation steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com