Wave-shaped combustion chamber

A wave-shaped, combustion chamber technology, applied to combustion engines, fuel injection devices, internal combustion piston engines, etc., can solve problems such as insufficient clearance volume utilization, and achieve the effects of improving fuel economy, reducing NOX, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

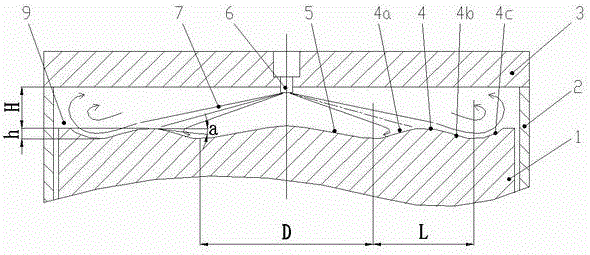

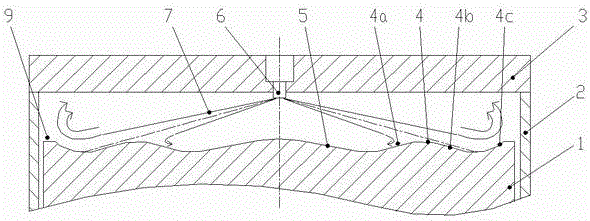

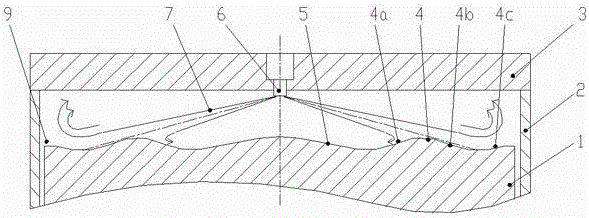

[0030] figure 1 and figure 2 A schematic diagram of the structure of the wave-shaped combustor is shown at the top dead center and the starting moment of fuel injection at 5 / 4 waves. The fuel injector 6 sprays high-pressure fuel into the combustion chamber composed of the piston body 1 , the cylinder liner 2 and the cylinder head 3 in the form of a spray 7 . The spray 7 collides on the wave-shaped mist guide I surface 4a, the spray 7 after the collision is divided into two parts, a small part of fuel flows into the combustion chamber central part 5, and most of the fuel continues to expand to the combustion chamber periphery 9. The fuel oil that expands toward the periphery 9 of the combustion chamber passes through the wave-shaped back mist guiding surface 4b and the wave-shaped facing fog guiding surface 4c again, so that the spray volume is further expanded, and because the piston moves up and down, the position of the spray 7 sprayed on the guiding surface is different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com