Fuel nozzle

A fuel injection nozzle and oil delivery technology, which is applied in fuel injection devices, special fuel injection devices, fuel injection devices with noise reduction measures, etc., can solve the problem of poor reliability of fuel injection nozzles, no flow, and affecting needle valves Opening and other problems to achieve the effect of improving noise and starting performance, improving cooling, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

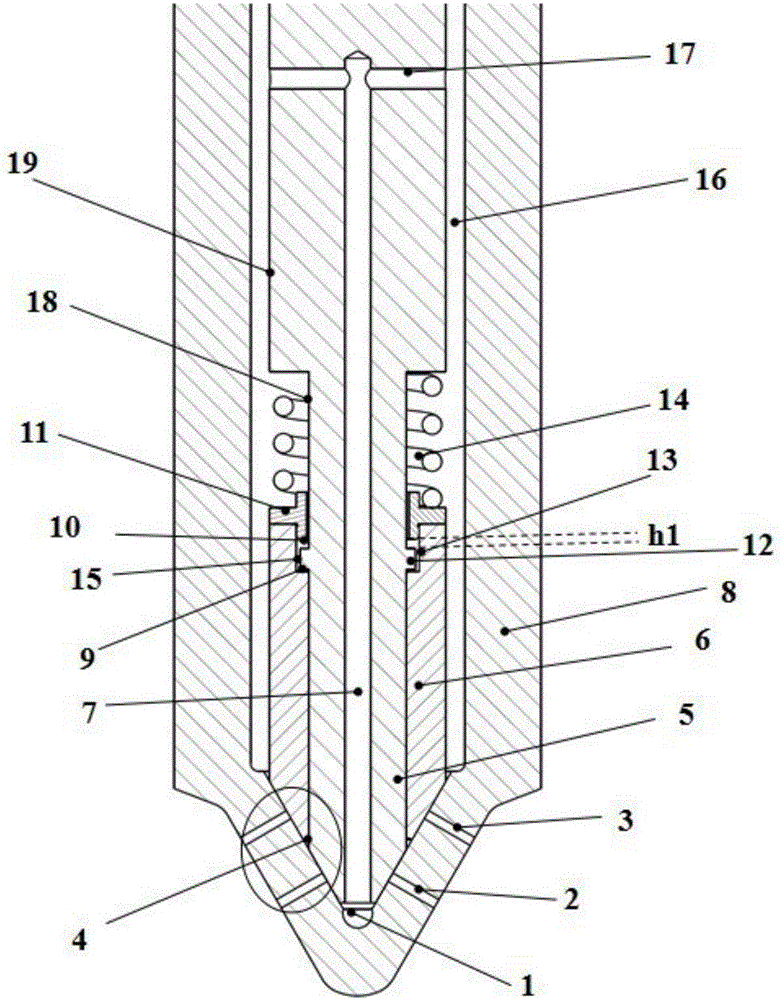

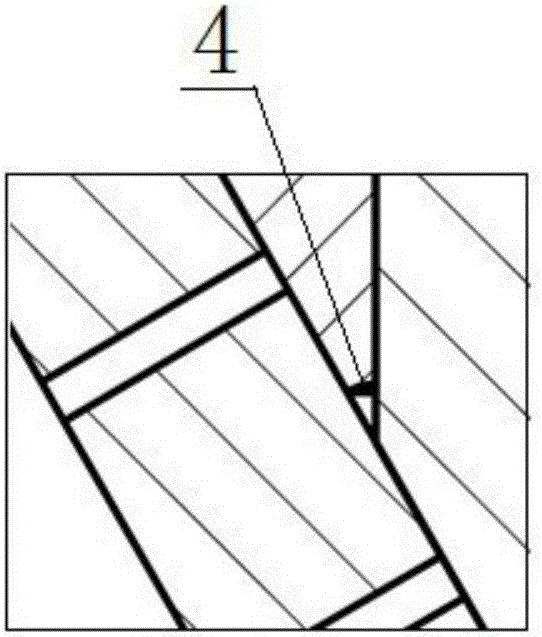

[0036] Such as figure 1 As shown, a fuel injection nozzle includes a needle valve, a needle valve body 8 coaxially arranged on the outer periphery of the needle valve, and an oil delivery channel arranged inside the needle valve body 8 .

[0037] The inside of the head of the needle valve body 8 is provided with a conical sealing surface, and two rows of spray holes are arranged alternately on the conical sealing surface, namely the upper row of nozzle holes 3 and the lower row of nozzle holes 2 .

[0038] The needle valve includes a first needle valve 5 with a variable cross-section cylindrical structure and a cylindrical second needle valve 6 . The first needle valve 5 and the second needle valve 6 are arranged coaxially, and both can move axially.

[0039] The first needle valve 5 includes a head cylinder 18 and a top cylinder 19 arranged above the head cylinder 18, and the diameter of the top cylinder 19 is greater than the diameter of the head cylinder 18; the middle par...

Embodiment 2

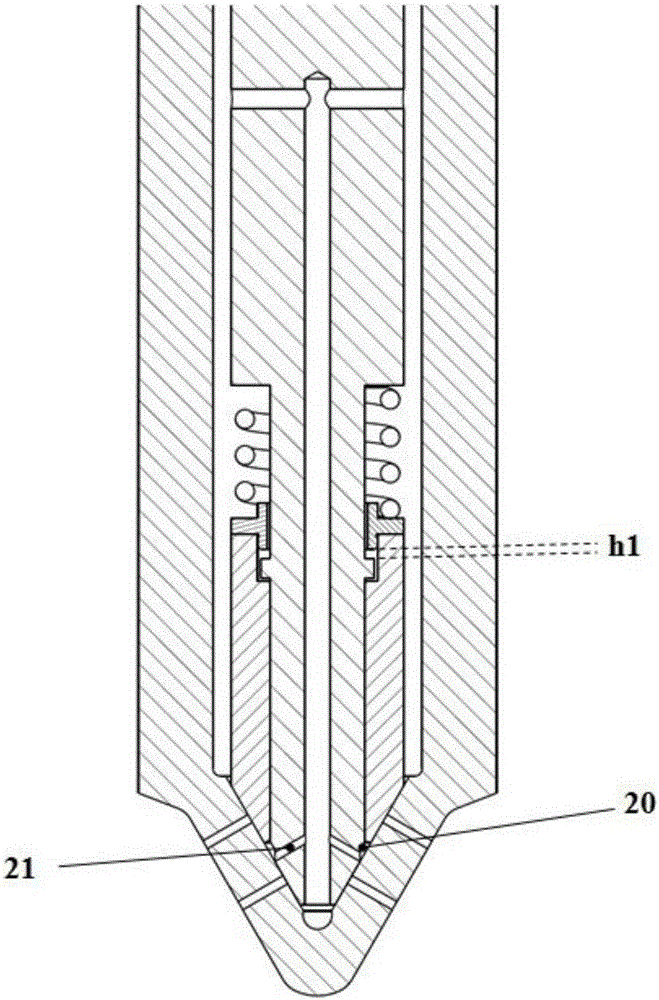

[0060] The structure and working principle of Embodiment 2 and Embodiment 1 are basically the same, and the only difference lies in the structural arrangement of the anti-seize mechanism. In embodiment 2, such as image 3 As shown, the anti-seize mechanism is the second annular groove 20 provided on the first sealing tapered surface of the head of the first needle valve 5 . The head of the first needle valve 5 is also provided with a plurality of side through holes 21 that can communicate the second annular groove 20 with the central shaft hole 7 . The diameter of the side through hole 21 is less than 1 / 2 of the diameter of the central shaft hole 7 .

[0061] The above-mentioned second annular groove 20 can prevent the guide surface between the first needle valve 5 and the second needle valve 6 from being stuck, and at the same time, it can also strengthen the fuel flushing of the area between the lower row of nozzle holes 2 and the upper row of nozzle holes 3 , to enhance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com