Composite carbon fiber oil cylinder capable of realizing oil supply by cylinder bottom and cylinder cover

A composite carbon fiber and cylinder head technology, applied in the field of hydraulic cylinders, can solve problems such as dimensional accuracy and roughness not meeting the design requirements, peeling off of the metal lining and carbon fiber cylinder, inconsistent expansion coefficients, etc., achieving significant weight reduction effects, Solve the effect of weak connection strength and inconsistent expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

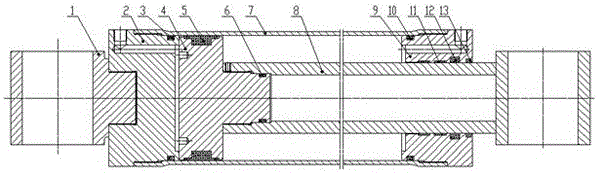

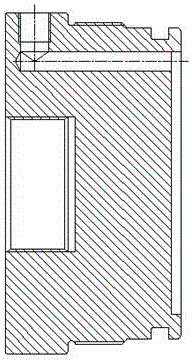

[0023] Such as figure 1 , figure 2 As shown, the composite carbon fiber cylinder with oil through the cylinder bottom and the cylinder head includes a cylinder bottom 2, a piston 4, a piston rod 8, a cylinder barrel 7 and a cylinder head 9 without metal lining, and the cylinder bottom 2 is connected to the cylinder barrel 7 There is a static seal 3 at the bottom of the cylinder, and the cylinder head 9 is sequentially provided with a dust-proof ring 13, a guide belt 11, and a static seal 10 for the cylinder head from the outside to the inside. The dust-proof ring 13 and the guide belt 11 are arranged between the piston rod 8 and the cylinder Between the covers 9, the static seal 10 of the cylinder head is arranged between the cylinder head 9 and the cylinder barrel 7, and a piston rod sealing ring 12 is also arranged between the piston rod 8 and the cylinder head 9, and the piston 4 is provided with a piston A sealing ring 5, a piston static seal 6 is arranged between the pi...

Embodiment 2

[0032] Such as figure 1 , figure 2 As shown, the composite carbon fiber cylinder with oil through the cylinder bottom and the cylinder head includes a cylinder bottom 2, a piston 4, a piston rod 8, a cylinder barrel 7 and a cylinder head 9 without metal lining, and the cylinder bottom 2 is connected to the cylinder barrel 7 There is a static seal 3 at the bottom of the cylinder, and the cylinder head 9 is sequentially provided with a dust-proof ring 13, a guide belt 11, and a static seal 10 for the cylinder head from the outside to the inside. The dust-proof ring 13 and the guide belt 11 are arranged between the piston rod 8 and the cylinder Between the covers 9, the static seal 10 of the cylinder head is arranged between the cylinder head 9 and the cylinder barrel 7, and a piston rod sealing ring 12 is also arranged between the piston rod 8 and the cylinder head 9, and the piston 4 is provided with a piston A sealing ring 5, a piston static seal 6 is arranged between the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com