Special valve for stone and pulverized coal

A special valve, pulverized coal technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of general valve application limitation, etc., and achieve the effect of high service life, simple and clear overall structure design, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

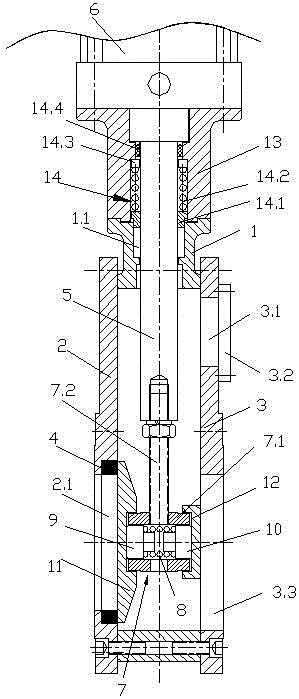

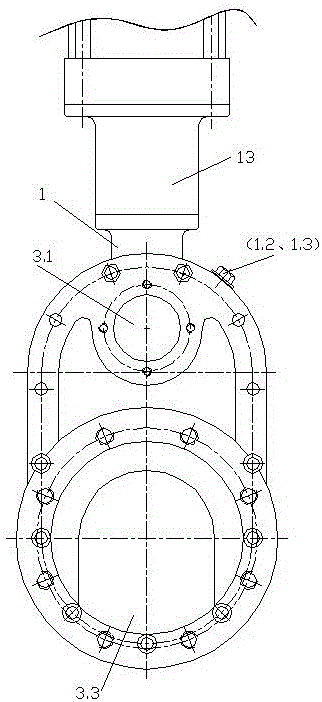

[0014] Example 1: A special valve for pebble and coal, including a metal valve body 1, left and right flanges (2, 3) connected to the two ends of the metal valve body 1, a valve seat hole 2.1 on the left flange 2, and installed on the valve The valve seat 4 of the seat hole 2.1, the center of the top side wall of the metal valve body 1 is provided with a valve stem hole 1.1, the valve stem hole 1.1 is provided with a valve stem 5, the top of the valve stem 5 is connected to the pneumatic actuator 6, and the bottom end of the valve stem 5 is connected The spring seat 7 includes a horizontal pipe body 7.1, a vertical screw 7.2 arranged in the center of the side wall of the horizontal pipe body 7.1, the screw 7.2 is screwed to the screw hole at the bottom end of the valve stem 5, and the horizontal pipe body 7.1 is provided with a spring 8. The left and right supporting mandrels (9, 10) sleeved at both ends of the spring 8, the horizontal tube body 7.1 is inserted into the counters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com