Light-transmitting container wall thickness detection apparatus and method based on machine vision

A light-transmitting container and machine vision technology, applied in the field of optical inspection, can solve problems such as low detection accuracy, resolution interference, and inaccurate thickness measurement, and achieve high-precision measurement results, good directional isolation, and high signal-to-noise ratio information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

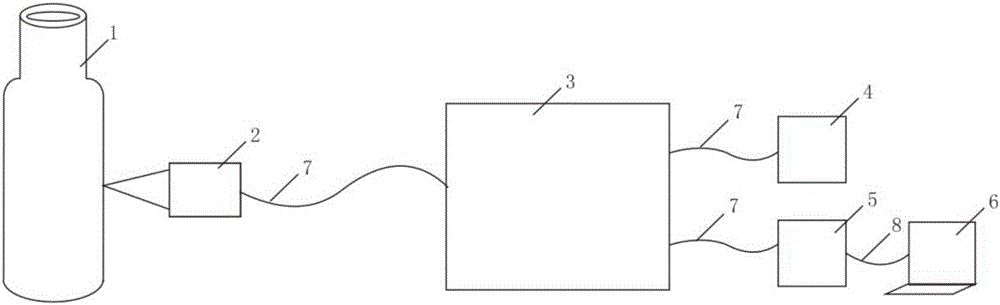

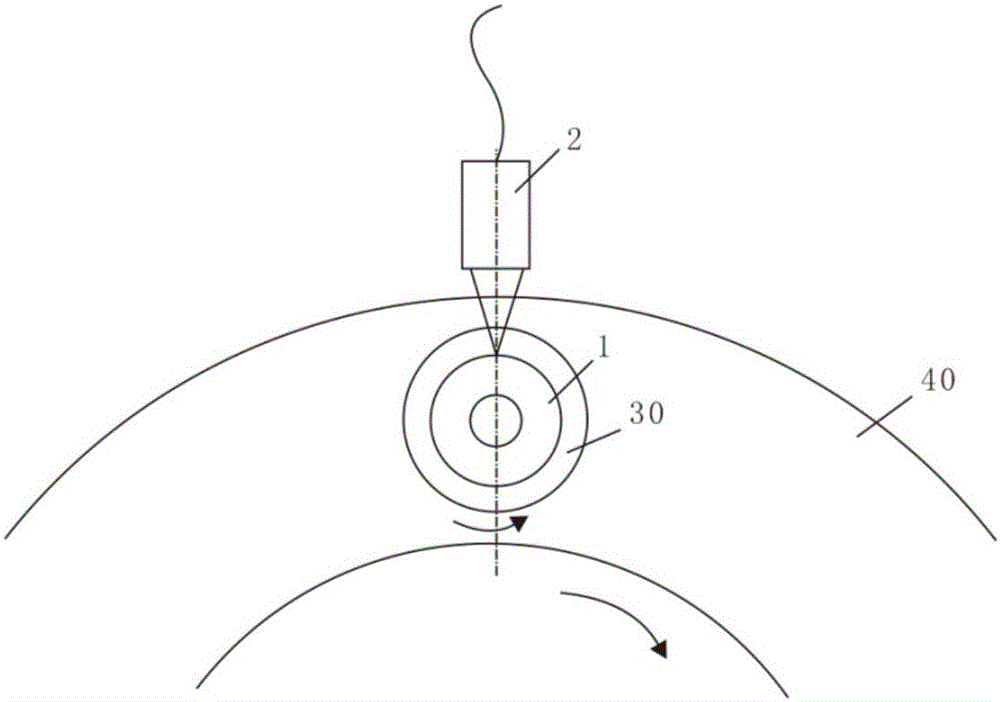

[0060] Such as figure 1 As shown, in this embodiment, the detection device includes: a detection lens 2, a spectroscopic system 3, a bright LED white light source 4, a fiber optic spectrometer 5, and a spectral data processing module 6 (implemented by a computer in this embodiment). figure 1 The glass bottle 1 to be tested, the transmission optical waveguide 7 and the data line 8 are also shown in .

[0061] The bright LED white light source 4 can emit white light as a continuous spectrum light source, can be applied to bottles of various colors, and has strong light output power. Of course, those skilled in the art should understand that the light source may be white light with different color temperatures, or a halogen light source or other light sources may be used.

[0062] The illumination light generated by the high-brightness LED white light source 4 is transmitted through the transmission optical waveguide 7 , one end of the transmission optical waveguide 7 is coupled...

Embodiment 2

[0070] In this embodiment, a more specific implementation manner is given.

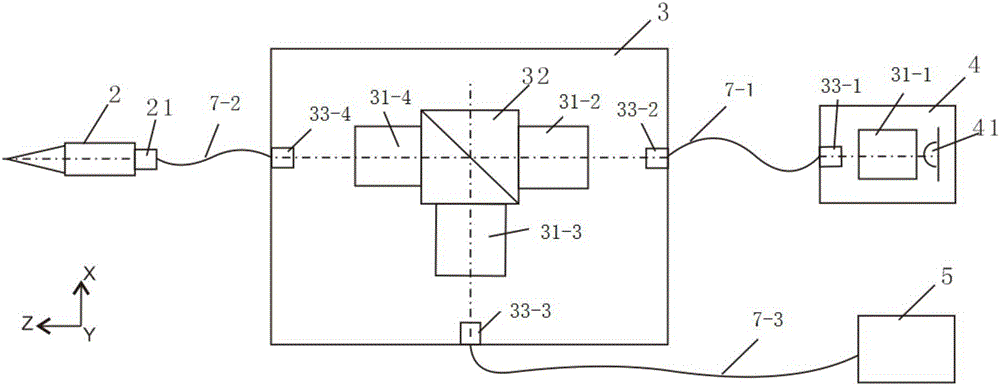

[0071] image 3 The detailed structure of each component is drawn in . As shown in the figure, the light source 4 includes an LED white light bead 41, a first lens group 31-1, and a first optical waveguide interface 33-1 (SMA905). The optical splitting system 3 includes: the second optical waveguide interface 33-2, the third optical waveguide interface 33-3 and the fourth optical waveguide interface 33-4, the second lens group 31-2, the third lens group 31-3 and the fourth The lens group 31 - 4 and the optical splitting device 32 , the optical lens 2 includes the fifth optical waveguide interface 21 . The spectroscopic system 2 communicates with the light source 4, the fiber optic spectrometer 5 and the detection lens 2 through transmission optical waveguides 7-1, 7-2 and 7-3.

[0072] The light emitted by the LED white light lamp bead 41 becomes parallel light after being collimated by the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com