Phase measurement deflection method for aspheric surface detection

A phase measurement and aspheric technology, applied in the field of optical detection, can solve the problems of difficulty in aspheric detection, avoid approximation or calibration, facilitate operation, and improve detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

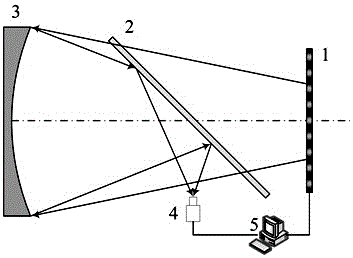

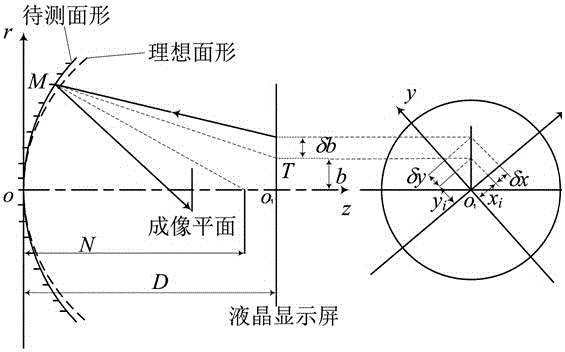

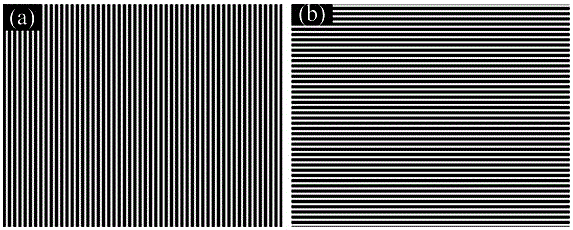

[0019] figure 1 is a schematic diagram of the detection device, wherein 1 is a liquid crystal display screen, 2 is a half mirror, 3 is a mirror to be tested, 4 is a camera, and 5 is a computer. During detection, sinusoidal stripes are generated on the liquid crystal display 1, and the sinusoidal stripes are compiled by a computer. The mirror surface of the mirror surface 3 to be tested is directly facing the liquid crystal display screen 1, that is, the connection line between the apex of the mirror surface 3 to be tested and the center of the liquid crystal display screen 1 is perpendicular to the liquid crystal display screen 1 surface, and the half-transparent mirror 2 is placed obliquely on the mirror surface 3 to be tested and Between the liquid crystal display screens 1, the light emitted from the liquid crystal display screen 1 illuminates the entire mirror surface 3 to be tested through the half mirror 2, and the light reflected by the mirror surface 3 is reflected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com