Matrix type mixed constant-speed sampling device

A sampling device and matrix technology, which is applied in the field of on-line monitoring devices for solid particles or gaseous pollutants, can solve the problems of narrow space, complex flue layout, and inability to represent the average concentration of flue particles or pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

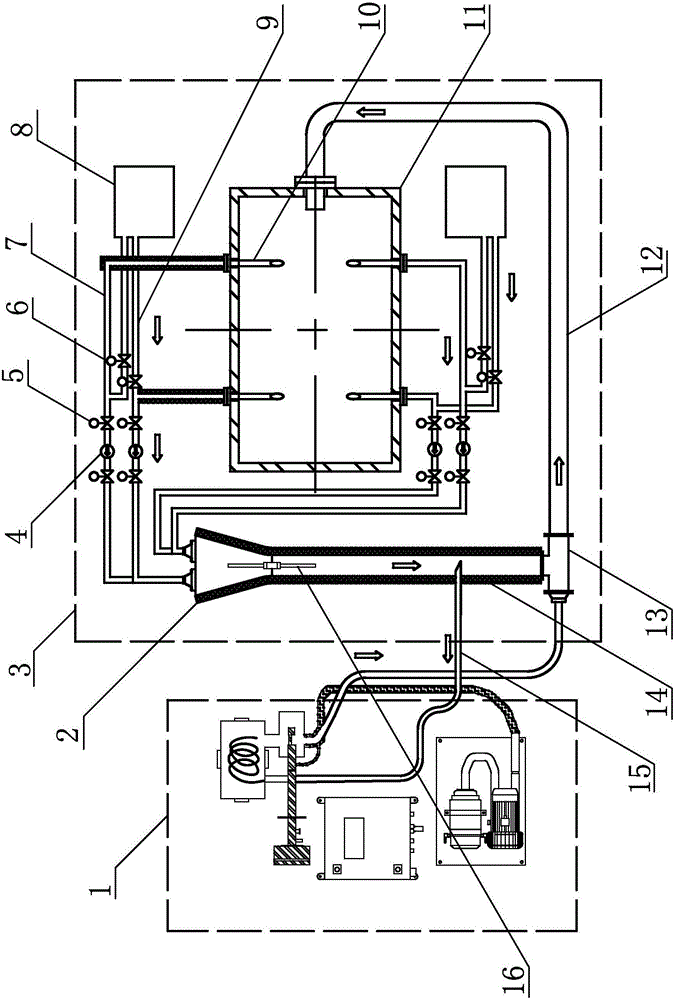

[0015] like figure 1 As shown, the matrix mixing constant velocity sampling device of the present invention includes an analysis unit 1 and a sampling unit 3, and the sampling unit 3 includes multiple sets of constant velocity circulation sampling devices. The constant velocity circulation sampling device comprises a sampling gun, and the sampling gun includes a gun body and a sampling tube 10, wherein the sampling tube 10 adopts a 316L stainless steel pipe with a diameter of 25 mm and a thickness of 2 mm, and the mouth of the sampling tube 10 is located inside the flue 11, and the sampling tube 10 Pitot tube speed measuring device (not shown in the figure) is arranged on the outside. The orifices of the plurality of sampling pipes 10 are evenly distributed around the same cross-section inside the flue 11, and the orifices face the direction of the incoming wind. According to the requirements of 4.2.4.2 of "Measurement of Solid Particulate Matter in Exhaust from Stationary Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com