Determination method for reasonable immersion time of coal seam water infusion

A technology of wetting time and coal seam water injection, which is applied in the determination of reasonable infiltration time for coal seam water injection, and the determination of reasonable infiltration time in the practice of coal seam water injection prevention and control of gas projects, can solve problems such as reducing gas release speed, and achieve strong practicability and reliable coal seam. The effect of water injection with reasonable soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: This embodiment takes the coal sample of mine A as the experimental coal sample to elaborate the technical solution of the present invention.

[0055] 1) Experimental method

[0056] Select the coal sample from Mine A as the experimental coal sample. The particle size of the coal sample is 1-3mm. After vacuuming, first fill a certain amount of methane gas to let the coal sample absorb and balance. After that, inject water into the coal sample. The water injection volume is 10% for design. Equilibrate for 3h, 6h, and 9h, and conduct the gas desorption speed test respectively.

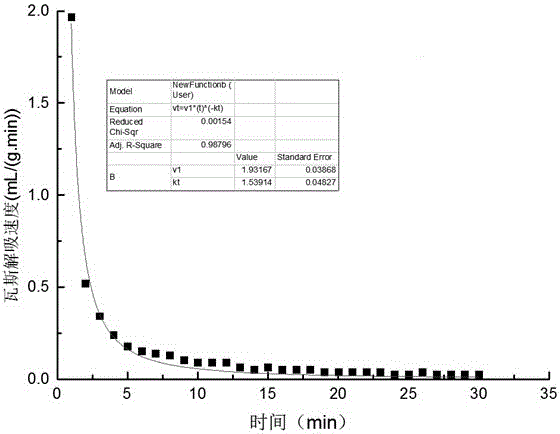

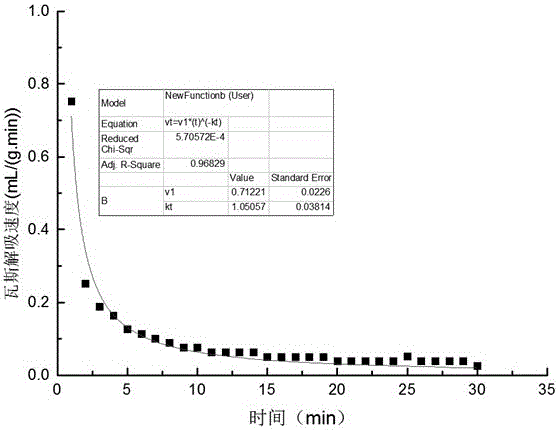

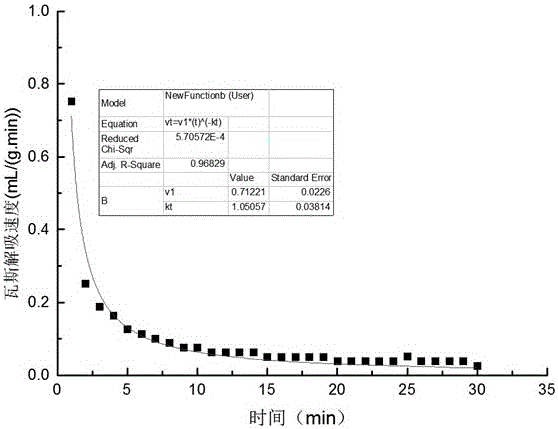

[0057] 2) For the test results of gas desorption speed of coal samples in mine A under different infiltration times, see Figure 1 to Figure 4 , figure 1 It is the graph of the gas desorption speed test that the equilibrium time is 3 hours in the present embodiment; figure 2 It is the graph of the gas desorption speed test that the equilibrium time is 6 hours in the present embod...

Embodiment 2

[0059] Embodiment 2: In this embodiment, the technical scheme of the present invention is described in detail by taking the coal sample of mine B as the experimental coal sample.

[0060] 1) Experimental method

[0061] The coal sample of Mine B was selected as the experimental coal sample. The particle size of the coal sample was 1-3mm. After vacuuming, a certain amount of methane gas was first filled to allow the coal sample to absorb and balance. After that, water was injected into the coal sample. Equilibrate for 3h, 6h, and 9h, and conduct the gas desorption speed test respectively.

[0062] 2) For the test results of gas desorption speed under different soaking times, see Figure 5 to Figure 8 , Figure 5 It is the graph of the gas desorption speed test that the equilibrium time is 3 hours in the present embodiment; Figure 6 It is the graph of the gas desorption speed test that the equilibrium time is 6 hours in the present embodiment; Figure 7 It is the graph of t...

Embodiment 3

[0064] Embodiment 3: the present embodiment elaborates the technical scheme of the present invention in detail with the C mine coal sample as the experimental coal sample

[0065] 1) Experimental method

[0066] The coal sample of Mine C was selected as the experimental coal sample. The particle size of the coal sample was 1-3mm. After vacuuming, a certain amount of methane gas was first filled to allow the coal sample to absorb and balance. After that, water was injected into the coal sample. Equilibrate for 3h, 6h, and 9h, and conduct the gas desorption speed test respectively.

[0067] 2) For the test results of gas desorption speed under different soaking times, see Figure 9 to Figure 12 , Figure 9 It is the graph of the gas desorption speed test that the equilibrium time is 3 hours in the present embodiment; Figure 10 It is the graph of the gas desorption speed test that the equilibrium time is 6 hours in the present embodiment; Figure 11 It is the graph of the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com