A Passive Current-Voltage Integrated Sensor

A technology integrating sensors and voltage sensors, applied in the field of power grid, can solve problems such as inconvenient installation, complex structure, creepage phenomenon, etc., and achieve the effects of convenient detection, small size, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

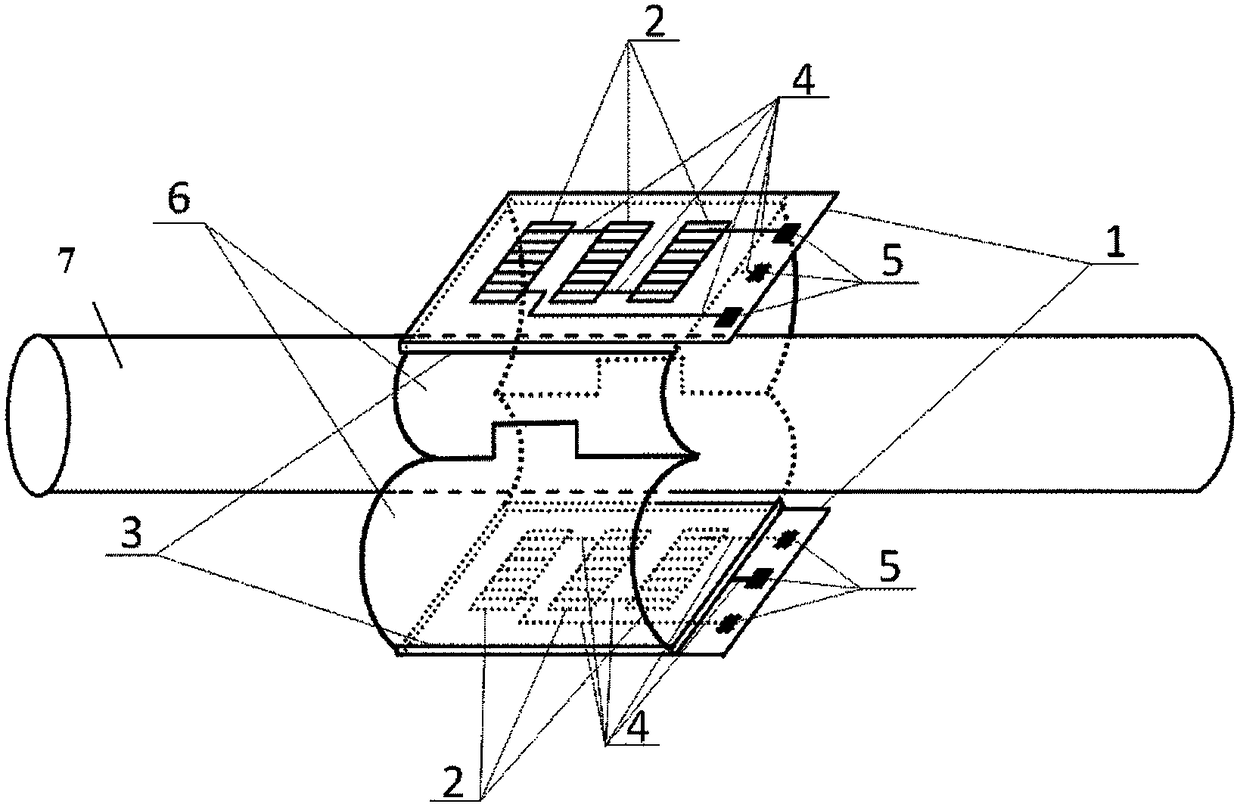

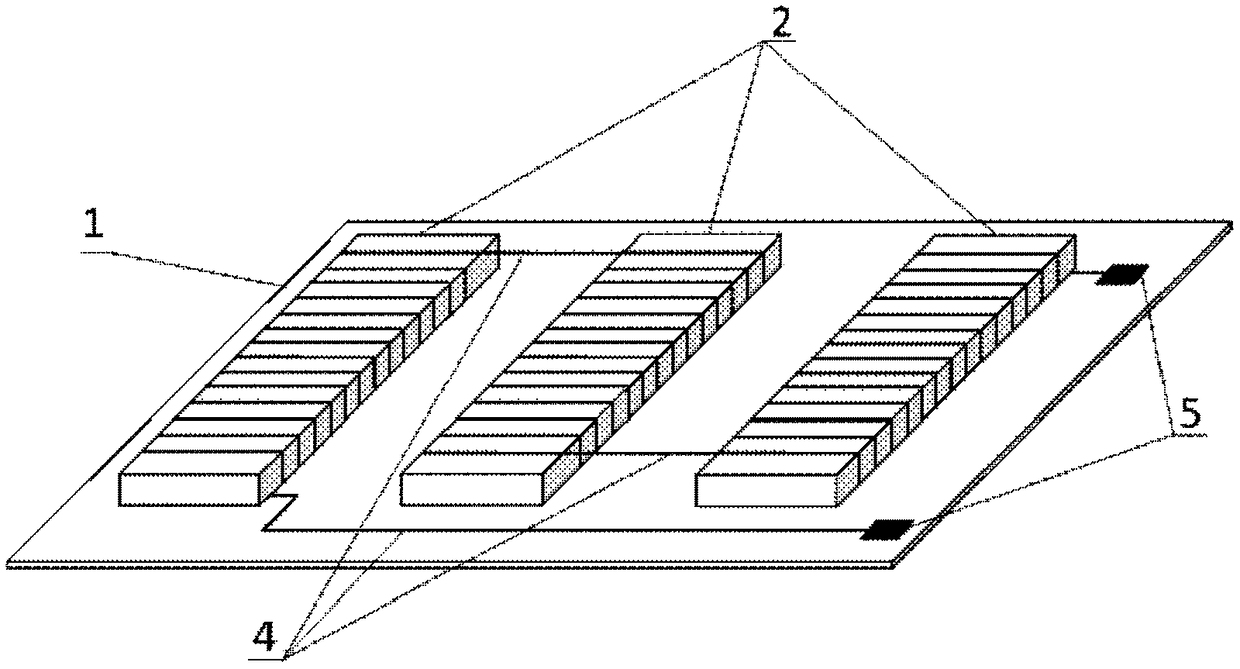

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

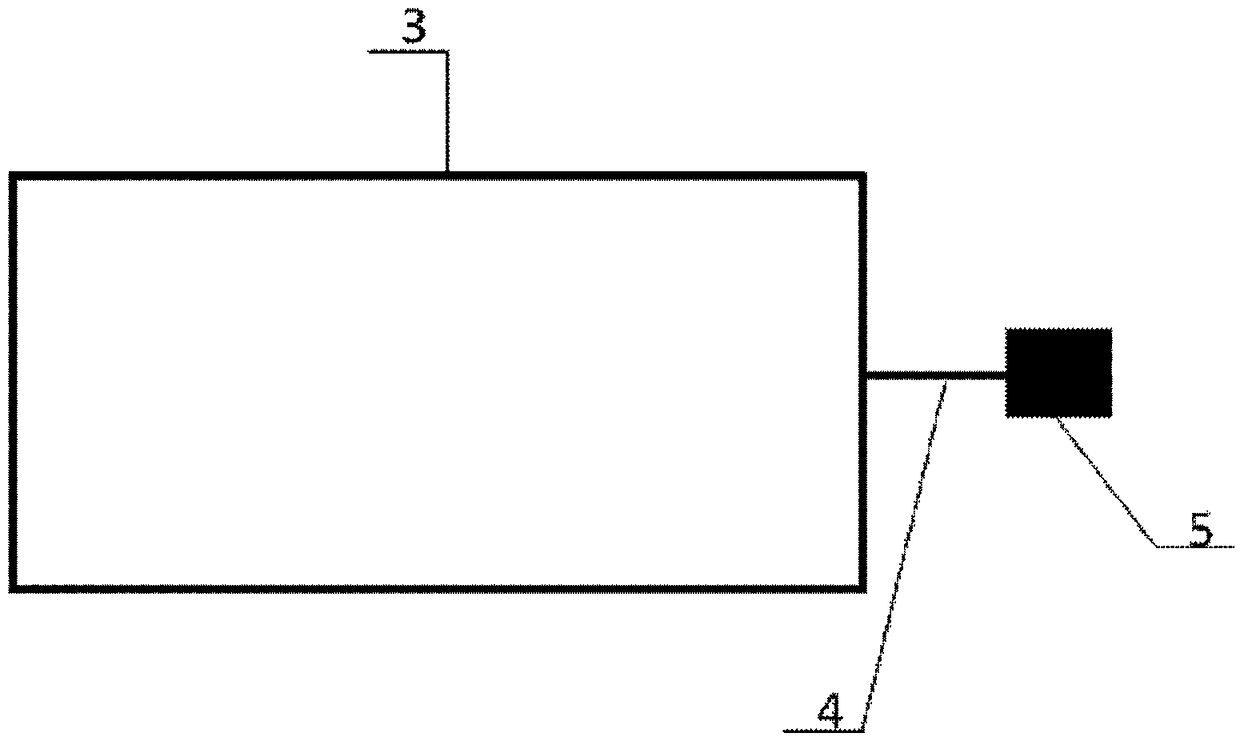

[0035] The passive current and voltage integrated sensor of the present invention can simultaneously detect passive current signals and voltage signals of an AC distribution network. Among them, the working principle of the current sensor is Faraday's law of electromagnetic induction. The alternating magnetic field generated by the AC signal in the transmission wire passes through the magnetic core coil to generate an induced electromotive force at both ends of the magnetic core coil. The electromotive force is proportional to the measured current. Through the electromotive force The magnitude of the measured current can be obtained. The working principle of the voltage sensor is the principle of electrostatic induction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com