Liquid crystal module and liquid crystal display screen

A liquid crystal module and backplane technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems that the direct type cannot be thinned and the cost of the side-mounted liquid crystal module is high, so as to improve the uniformity of illumination and achieve thin The effect of optimizing the design and preserving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

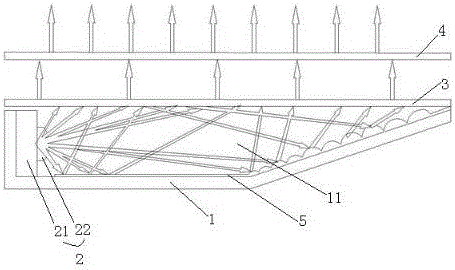

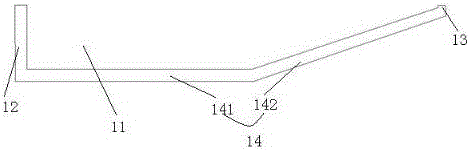

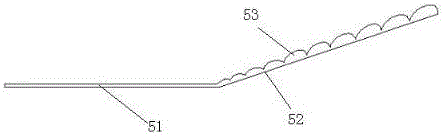

[0030] This embodiment provides a liquid crystal module, such as figure 1 and 2 As shown, it includes a backplane 1, a backlight 2, a diffusion plate 3 capable of diffusing the light emitted by the backlight 2, an optical film (not shown in the figure), glass 4 and a reflector; the backplane 1 includes The wedge-shaped bottom plate 14 and the first side plate 12 and the second side plate 13 arranged at both ends of the bottom plate 14 form a wedge-shaped cavity 11 with an opening. The backlight 2 is disposed on the inner surface of the first side plate 12 , and the glass 4 and the diffusion plate 3 are sequentially stacked at the opening of the cavity 11 of the back plate 1 to close the opening. The optical film is located between the glass 4 and the diffusion plate 3, and is attached to the upper surface of the diffusion plate 3, so that the light emitted by the backlight 2 will pass through the diffusion plate 3 and the optical film in sequence, and finally pass through the...

Embodiment 2

[0037] This embodiment provides a liquid crystal module, the structure of which is basically the same as that of Embodiment 1, the difference is that, as Figure 4 and Figure 5 As shown, the backlight 2 includes a PCB board 21, a light source 22 installed on the PCB board 21 and electrically connected to the PCB board 21, and a light source 22 sleeved on the light source 22 for generating Optical coupler 23 for light mixing. The optical coupler 23 can be made of glass, PMMA, PC or MS and other materials with good optical properties and chemical stability, which specifically includes a first side 231, a second side 232 and a top side 233 Construct a body with an opening facing the light source 22, the body of the optical coupler 23 is connected to the PCB board 21, the PCB board 21 covers the opening of the body and forms a closed space 234 with the body, the light source 22 is placed Inside the enclosed space 234 . The body is in an inverted trapezoid shape, that is, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com