Precise temperature control circuit of anti-irradiation infrared detector refrigeration motor

A technology of infrared detectors and refrigeration motors, applied to instruments, temperature control, non-electric variable control, etc., can solve problems such as low reliability, large volume, and heavy weight, and achieve overcoming rise time, accurate temperature sampling, and reduction The effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0025] The control part of the circuit integrated motor driving circuit of the present invention has small volume and high integration degree, and meets the requirements of the infrared detector for small volume, multi-function and high reliability.

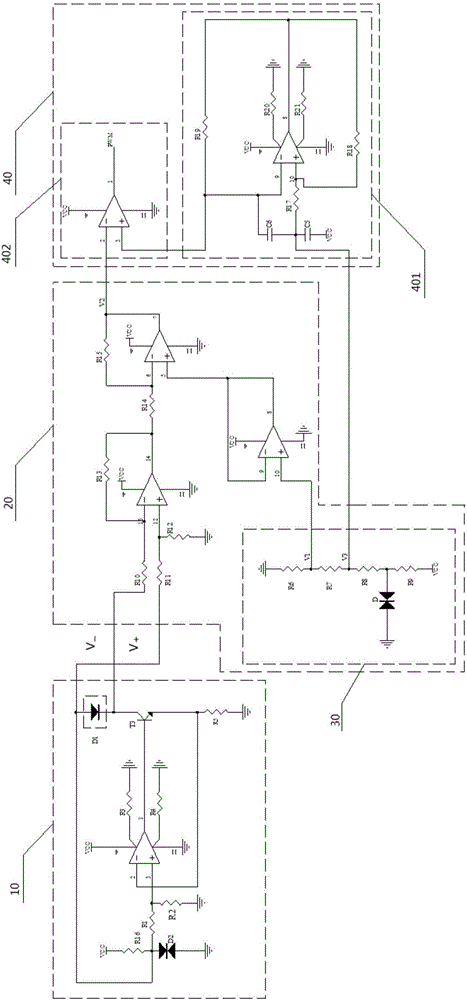

[0026] The precise temperature control circuit of the anti-radiation infrared detector refrigeration motor of the present invention, such as figure 1 As shown, it includes a temperature control sampling circuit 10, a temperature control circuit 20 and a PWM generating circuit 40; by adjusting the bias resistors R3, R4, R20, R21, the operational amplifier in the negative feedback constant current source circuit and the operational amplifier in the triangular wave generating circuit 401 are set. The bias state of the operational amplifier increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com