Calculation and control method for welding material actual consumption

A technology of welding materials and actual consumption, which is applied in calculation, special data processing applications, instruments, etc., can solve problems such as loss of control reference, low accuracy, and difficulty in determining the coefficient of addition, so as to reduce the consumption of welding materials and realize Quota management, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention proposes a method that can directly calculate the actual amount of welding material used in the weld, and then collect the welding materials used by the weld or component unit according to the production flow designed by the enterprise, and obtain the corresponding welding material details (including material name, Brand, specification, quantity and other information), and use the details as the basis for management to realize the fine control of the process, that is, to achieve a certain amount of material, the same as the welding material. It can not only ensure the validity and accuracy of the data, but also realize the management and control of the process, so as to achieve the purpose of reducing the production cost of the enterprise.

[0021] A calculation and control method for the actual amount of welding materials, comprising the following steps:

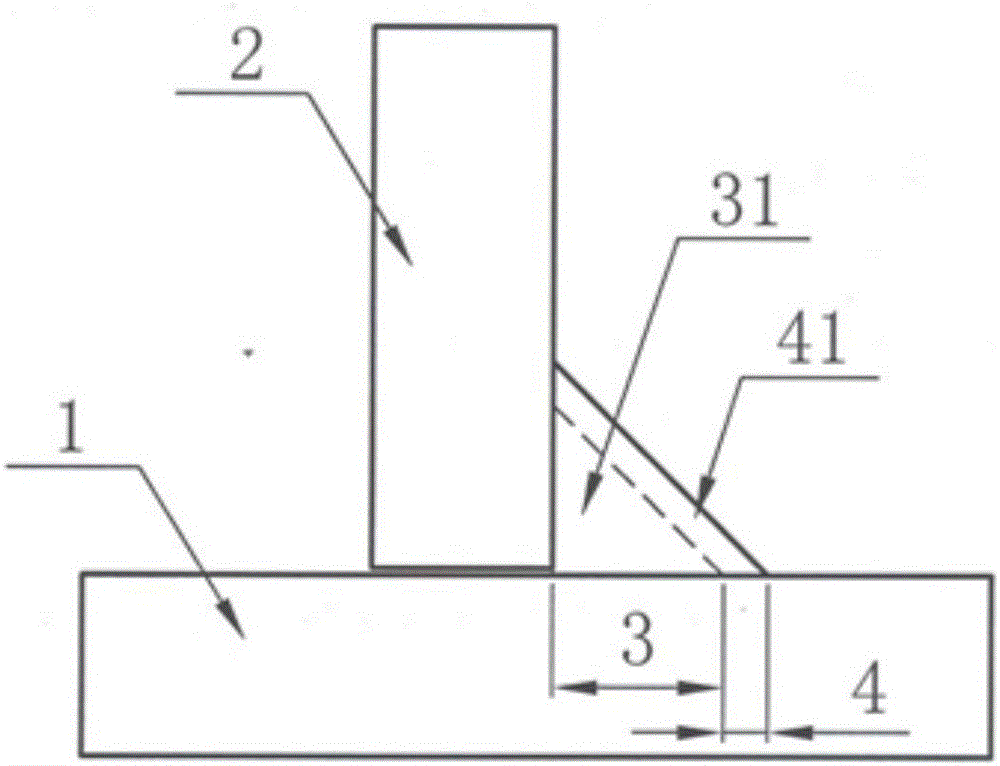

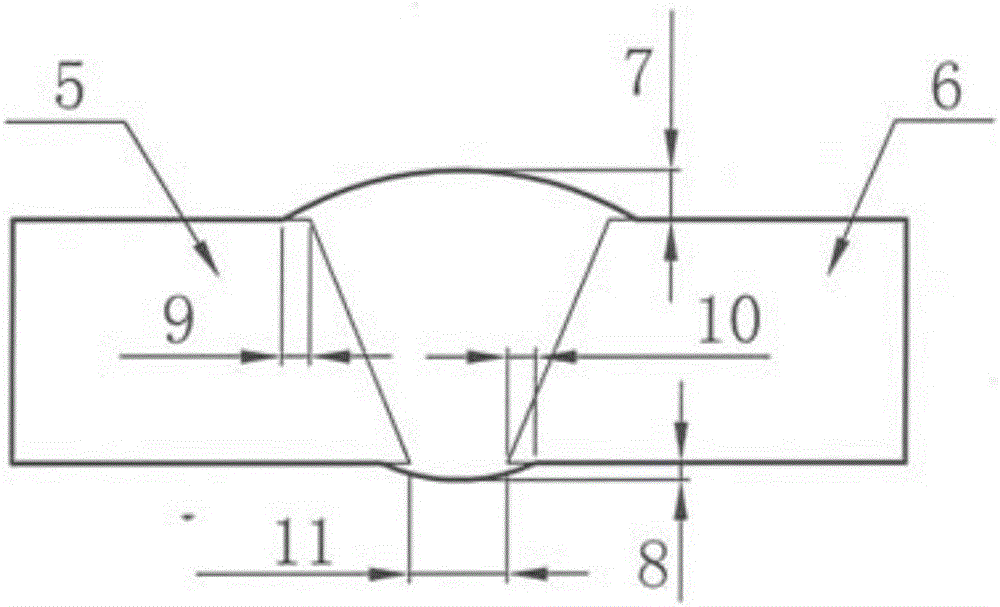

[0022] a The average value of various actual welding redundancy of different joint forms is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com