Array camera observation method for detecting structure surface in turbid media

A technology of structured surface and array camera, which is applied in image data processing, instrumentation, computing, etc., can solve problems such as difficulty in obtaining a clear apparent image, difficulty in ensuring image clarity, and narrowing of the field of view, so as to shorten the observation distance , Improving the imaging clarity and increasing the field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

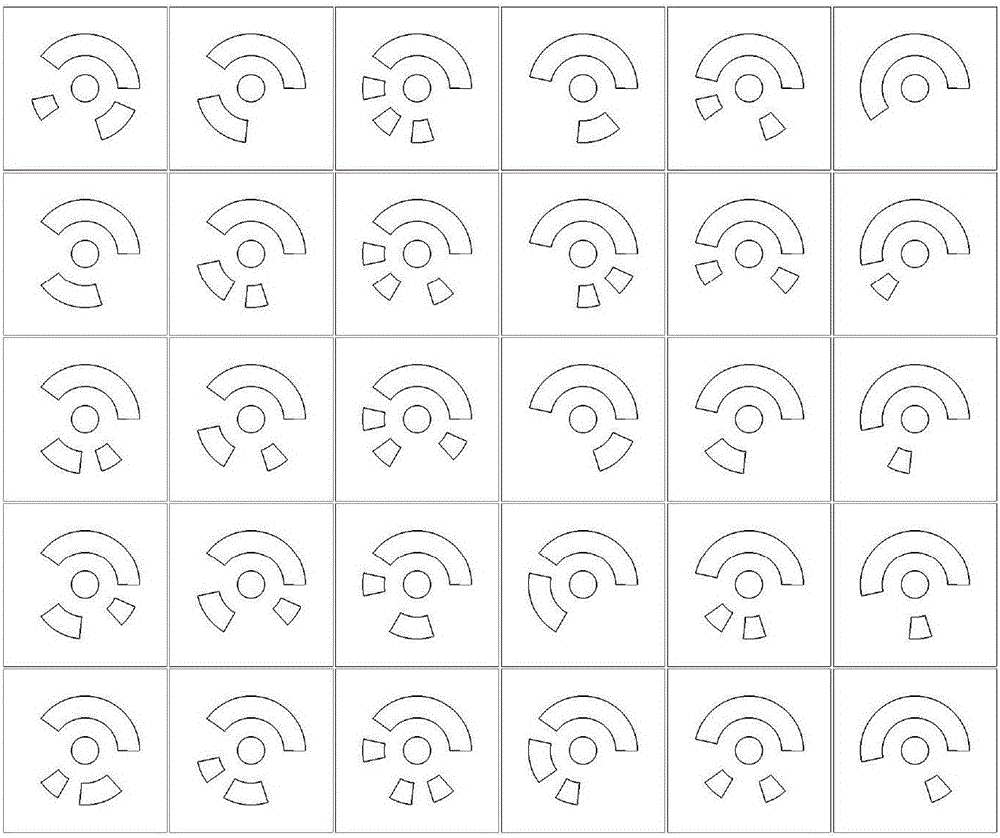

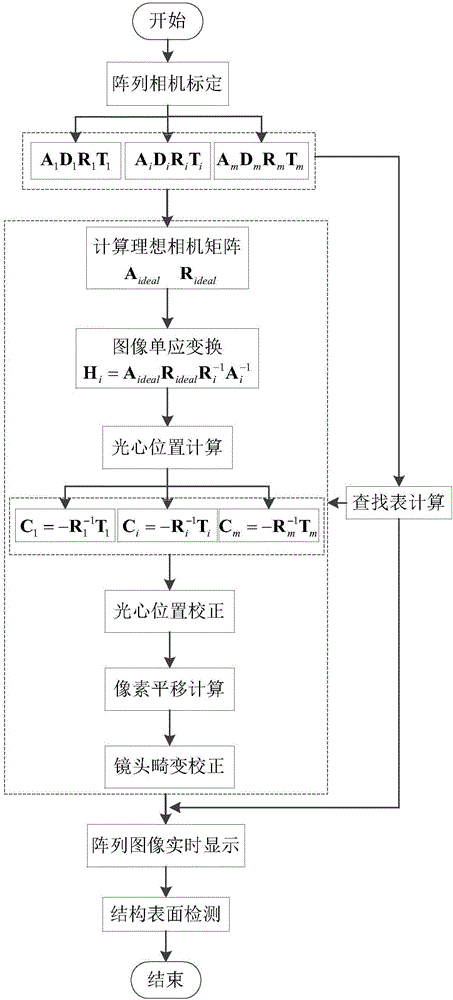

[0031] Prepare a camera array device: the cameras are regularly arranged on a rigid frame according to the grid arrangement, and the image resolution, aperture, focal length and other camera and lens parameters of all cameras are the same, and the field of view of a single camera is about 8cm×6cm. The observation distance is about 11cm, the horizontal distance between adjacent cameras is slightly smaller than the width of a single camera's field of view, and the vertical distance is slightly smaller than the height of a single camera's field of view, and the cameras should be kept as parallel as possible; this arrangement can make full use of The image resolution of the camera can ensure a certain overlap area between adjacent cameras, thereby ensuring the continuity of the final array image. If the structural surface inspection is carried out under underwate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com