Battery module

A technology for battery modules and battery packs, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of difficult heat dissipation, the lack of heat dissipation function of thermal conductive sheets, and the increase of components, so as to promote heat dissipation and solve the problem of thermal runaway. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

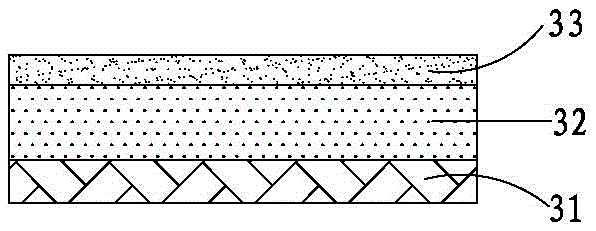

[0053] The making of composite heat dissipation layer 3: will (NH 4 ) 2 C 2 o 4 Mix it with polyvinylidene fluoride at a mass ratio of 80:20 to make a heat absorbing layer 32 slurry, then coat the heat absorbing layer 32 slurry on a copper sheet, and paint after drying to obtain a composite heat dissipation layer 3 . Wherein, the thickness of the prepared composite heat dissipation layer 3 is 15mm.

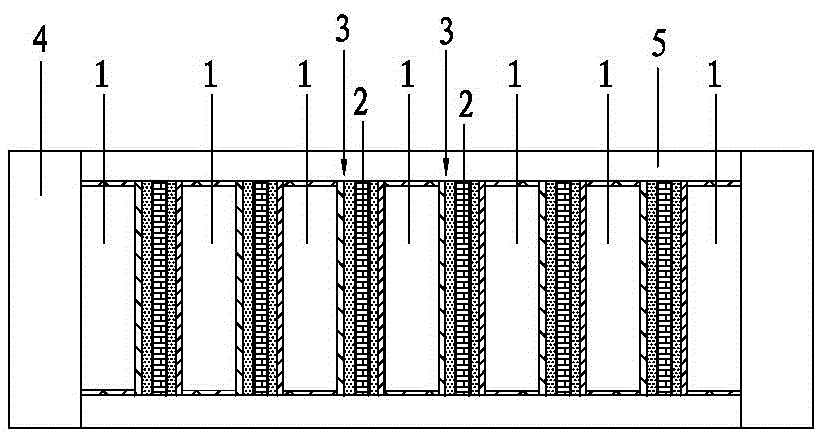

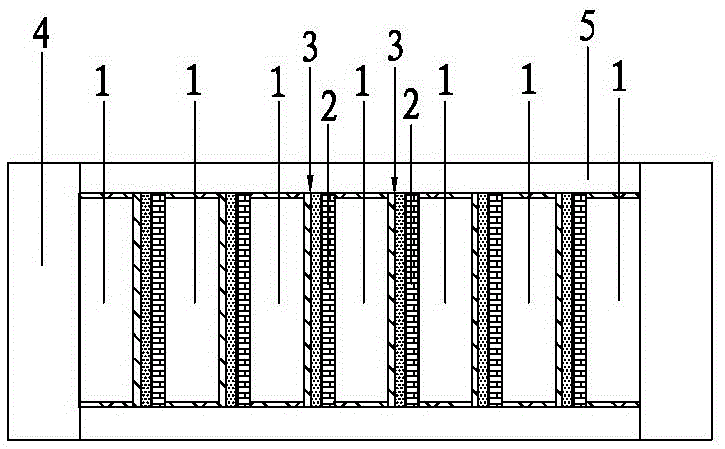

[0054] Production of battery modules: connect a plurality of single cells 1 in series and / or in parallel to form a battery pack, and set a module frame composed of two end plates 4 and two side plates 5 outside the battery pack; A thermal insulation pad 2 is provided between two adjacent single cells 1, and a composite heat dissipation layer 3 is provided between two adjacent single cells 1 and the thermal insulation pad 2, and the side edges of the copper sheet in the composite thermal radiation layer 3 are Welded on the side plate 5, the battery module of the present inventi...

Embodiment 2

[0056] The difference with embodiment 1 is:

[0057] Fabrication of the composite heat dissipation layer 3: Mix ethylene glycol crystals and polyvinylidene fluoride at a mass ratio of 70:30 to make a heat absorbing layer 32 slurry, then coat the heat absorbing layer 32 slurry on a silver sheet, and after drying Paint is then applied to obtain the composite heat dissipation layer 3 . Wherein, the thickness of the prepared composite heat dissipation layer 3 is 10mm.

[0058] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0060] The difference with embodiment 1 is:

[0061] Production of the composite heat dissipation layer 3: Mix sucrose and styrene-butadiene rubber at a mass ratio of 90:10 to make the heat-absorbing layer 32 slurry, then coat the heat-absorbing layer 32 slurry on the silver sheet, and apply polyurethane coating after drying , to obtain the composite heat dissipation layer 3 . Wherein, the thickness of the prepared composite heat dissipation layer 3 is 10mm.

[0062] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com