Device for determining the topography of the charge surface in a shaft furnace

A furnace charge and shaft furnace technology, applied in the field of topography devices, can solve problems such as cost, and achieve the effect of low control cost, low equipment cost, and simple design scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

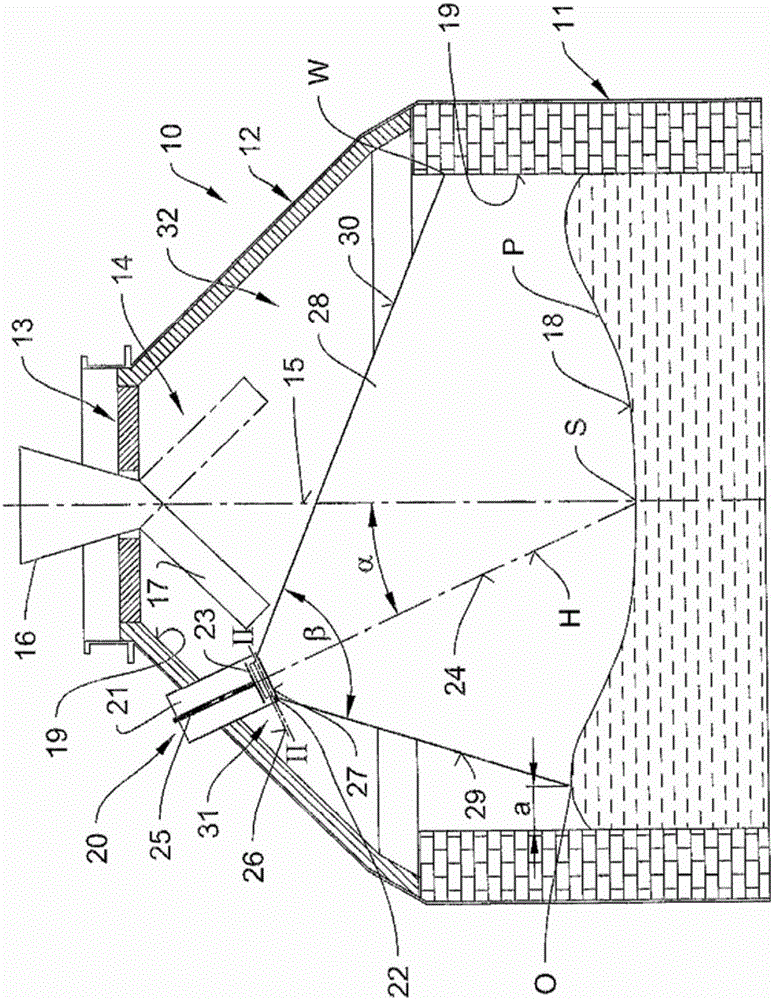

[0027] figure 1 Shown is a shaft furnace 10 which essentially consists of a furnace lower part 11 , a furnace upper part 12 and a furnace cover 13 , in which a charging device is integrated, which is designed here as a rotating chute 14, the charging device can be pivoted about a vertical axis 15, so that the pouring ramp 17 connected to the funnel opening 16 of the rotating chute 14 can be positioned in a defined manner, which can be positioned relative to the vertical The axis 15 is adjusted in terms of inclination.

[0028] The rotating slide 14 is used to alternately supply the shaft furnace 10 figure 1 The layers of coke and charge are explicitly not shown in detail in , where layers that are defined as precisely as possible are sought in order to achieve a reproducible blast furnace process. For this reason, it is necessary to determine the surface topography of the topmost layer as precisely as possible before applying it to subsequent layers.

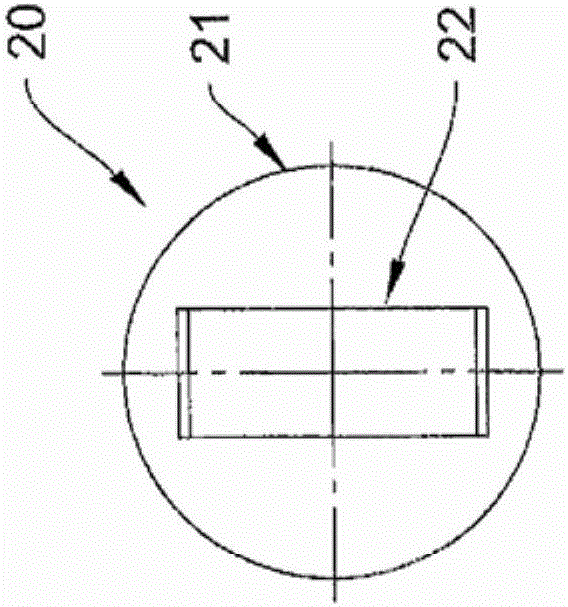

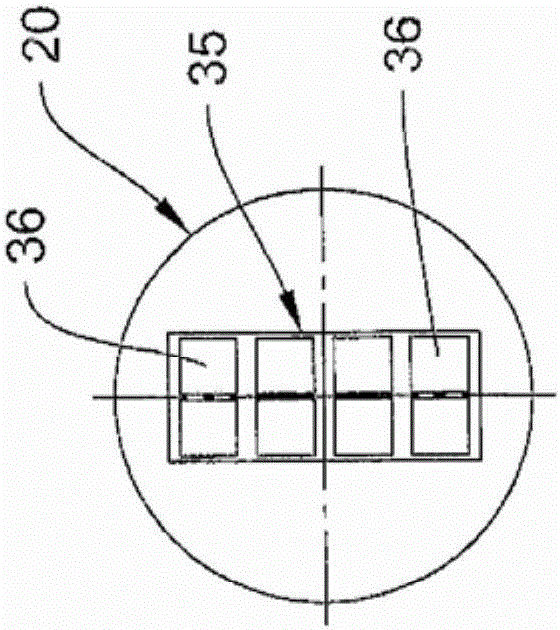

[0029] to detect fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com