Flexible transparent electric conduction film coating material doping graphene and white graphene

A white graphene, transparent conductive film technology, used in conductive coatings, coatings, polyurea/polyurethane coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

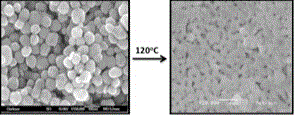

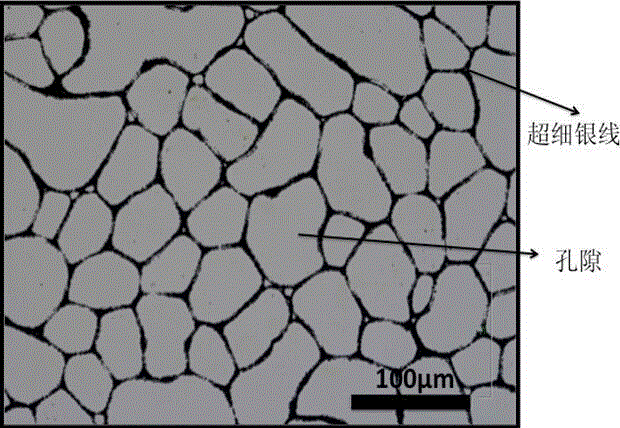

Method used

Image

Examples

Embodiment 1

[0055] A kind of flexible transparent conductive film of doped graphene and white graphene, described conductive paint layer comprises the raw material of following weight percent:

[0056] Isopropanol 20%

[0057] n-Butanol 20%

[0058] Ethylene glycol monoethyl ether 10%

[0059] Acetyl Tributyl Citrate 5%

[0060] Adhesive 5%

[0061] Division 85 5%

[0062] Ethyl cellulose 1%

[0063] 20-30 nanometer silver powder 5%

[0064] 100-400 nanometer silver powder 15%

[0065] Graphene homogeneous solution 3%

[0066] White graphene homogeneous solution 5%

[0067] (1) Weigh the raw materials of the above formula according to the proportion, put the above nano-silver powders into the oven at 150°C respectively, and place them in the oven for 30 minutes to remove the moisture in the raw materials;

[0068] (2) Add weighed isopropanol, n-butanol, ethylene glycol monoethyl ether and ethyl cellulose into the container, put the mixture into a special stirrer and stir at 1000r...

Embodiment 2

[0074] A kind of flexible transparent conductive film of doped graphene and white graphene, described conductive paint layer comprises the raw material of following weight percent:

[0075] Isopropanol 20%

[0076] n-Butanol 20%

[0077] Ethylene glycol monoethyl ether 10%

[0078] Acetyl Tributyl Citrate 5%

[0079] Adhesive 5%

[0080] Division 85 4.6%

[0081] Ethylcellulose 1.4%

[0082] 20-30 nanometer silver powder 4.5%

[0083] 100-400 nanometer silver powder 14.5%

[0084] Graphene homogeneous solution 2.5%

[0085] White graphene homogeneous solution 5.5%

[0086] (1) Weigh the raw materials of the above formula according to the proportion, put the above nano-silver powders into the oven at 150°C respectively, and place them in the oven for 30 minutes to remove the moisture in the raw materials;

[0087] (2) Add weighed isopropanol, n-butanol, ethylene glycol monoethyl ether and ethyl cellulose into the container, put the mixture into a special stirrer and st...

Embodiment 3

[0093] A kind of flexible transparent conductive film of doped graphene and white graphene, described conductive paint layer comprises the raw material of following weight percent:

[0094] Isopropanol 20%

[0095] n-Butanol 20%

[0096] Ethylene glycol monoethyl ether 10%

[0097] Acetyl Tributyl Citrate 5%

[0098] Adhesive 5%

[0099] Division 85 4.3%

[0100] Ethylcellulose 1.7%

[0101] 20-30 nanometer silver powder 6%

[0102] 100-400 nanometer silver powder 16%

[0103] Graphene homogeneous solution 1%

[0104] White graphene homogeneous solution 1%

[0105] (1) Weigh the raw materials of the above formula according to the proportion, put the above nano-silver powders into the oven at 150°C respectively, and place them in the oven for 30 minutes to remove the moisture in the raw materials;

[0106] (2) Add weighed isopropanol, n-butanol, ethylene glycol monoethyl ether and ethyl cellulose into the container, put the mixture into a special stirrer and stir at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com