[0007] 1. The base knuckles of the prosthetic fingers have many components, and the

assembly relationship is complicated. It is difficult to effectively and accurately locate the components, and the

assembly is difficult. In particular, the base knuckle structures of some existing prosthetic fingers have simple assembly structures As a result, the working reliability of the base knuckle is poor, and it is prone to failure

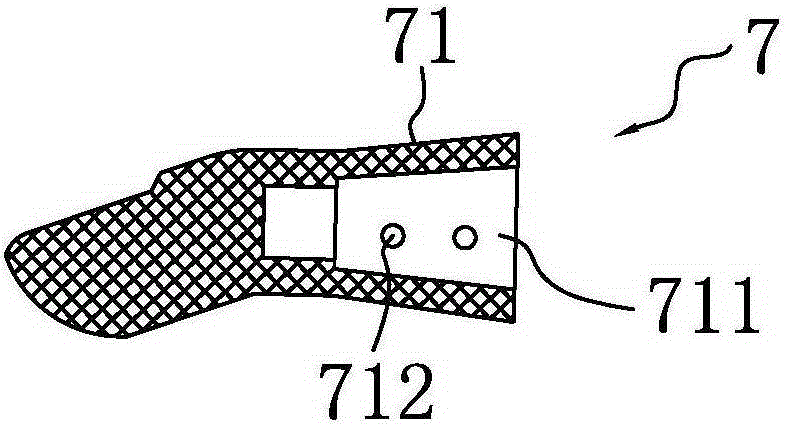

[0008] 2. In some existing prosthetic fingers, the connection structure between the base phalanx and the base joint of the

prosthesis finger is complicated, and the base phalanx of the finger is difficult to assemble on the base joint structure, and cannot be assembled simply and effectively

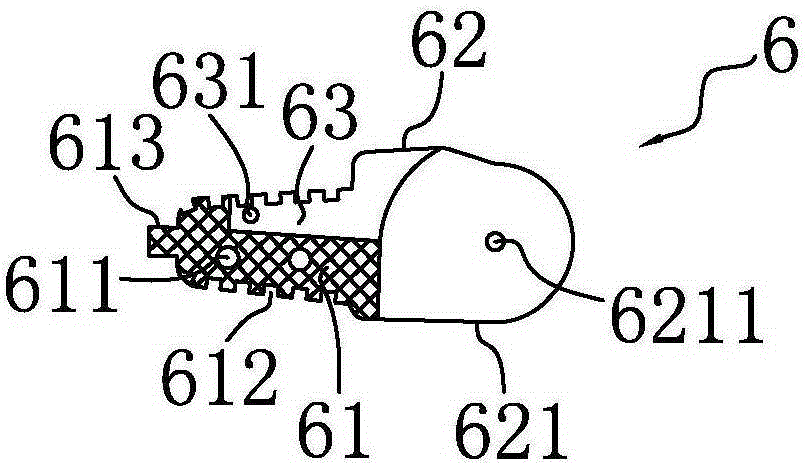

[0009] 3. For some existing prosthetic fingers that use

cable transmission for proximal knuckles, the proximal end of the transmission

rope is connected to the worm gear, but the specific connection structure adopted is not convenient for assembly, and the proximal end of the transmission

rope is also prone to fall off. Not conducive to reliable use of prosthetic hands

[0010] 4. For some existing prosthetic fingers, the proximal knuckles are driven by cables. Frequent

finger flexion and

finger extension operations will easily cause the transmission

rope to be rubbed and scratched on the base knuckles of the finger. Long-term use will easily cause the transmission rope to wear or even break , affecting the service life of the

cable transmission mechanism

[0011] 5. In some existing prosthetic fingers, the proximal knuckle of the finger and the base knuckle of the finger are connected by a stretch spring to realize the automatic reset of the proximal knuckle of the finger when the finger is extended, and the end of the stretch spring is fixed. The connection method, so the tension spring is frequently subjected to the compound action of tension and

bending moment, and long-term use will cause the tension spring to undergo bending

residual deformationThis will cause the fingers of the

prosthesis to flex and spread out of position, reducing the performance of the prosthetic fingers and prosthetic hands

[0012] 6. Some existing prosthetic fingers do not distinguish between the far knuckle and the near knuckle of the finger in structure, which is not convenient for the assembly of the near knuckle of the finger and other parts, or the near knuckle of the finger and the far knuckle of the finger The connection method of using end face bonding and then connecting with other connectors has poor connection reliability and the structure is not beautiful enough.

[0013] 7. The existing prosthetic fingers, due to the aforementioned problems in some of their structures, lead to poor working reliability of the entire prosthetic finger and are not easy to assemble

However, in some existing prosthetic thumbs, the structure between the proximal knuckle of the

thumb and the base knuckle of the thumb is very different from the connection structure between the proximal knuckle and the distal knuckle of the general prosthetic finger (non-thumb), This requires the

special design and manufacture of the structure of the thumb, or the

special design and manufacture of the structure of the proximal knuckle of the thumb and the base knuckle of the thumb. The difference between the prosthetic thumb and the general prosthetic finger will cause additional

workload and

processing costs. The versatility of components is also poor, which is not conducive to reducing costs

[0015] 9. The thumb has two postures: opposite palm and side palm. Therefore, the thumb of the

prosthetic limb needs to perform posture rotation movement, but the installation structure adopted by the thumb of the existing

prosthetic limb, the wires connected to the motor are drawn from the side, so that the thumb of the

prosthetic limb is in the working position. When changing the posture of the side palm and the opposite palm, the wires are pulled, and long-term use will cause the wires to break. In fact, the wires of this type of prosthetic thumb are often broken.

[0016] 10. Due to the above-mentioned problems in the existing prosthetic thumb, the entire prosthetic finger has a high cost, is prone to failure, and has poor working reliability;

[0017] 11. For some existing prosthetic hands, the general prosthetic fingers (four other prosthetic fingers except the thumb) are installed in the following way: the general prosthetic finger and the finger connector of the prosthetic hand are connected by a finger axial single screw, Generally, when the finger is straightened, the single screw in the axial direction of the finger is in the same direction as the finger, and the connection is not reliable. Short-term use will cause the connection to loosen.

[0018] 12. The existing prosthetic hands, due to the above-mentioned problems in some of their structures, lead to poor reliability and high cost of prosthetic hands

Login to View More

Login to View More  Login to View More

Login to View More