A control system and control method for intelligent sorting of lithium batteries

A control system and lithium battery technology, applied in sorting, printing, typewriter and other directions, can solve the problems of difficult to meet the requirements of mass production, complicated mechanical structure and technological process, low level of automation, etc., to achieve data sharing, reduce labor Effects of interventions, good field monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

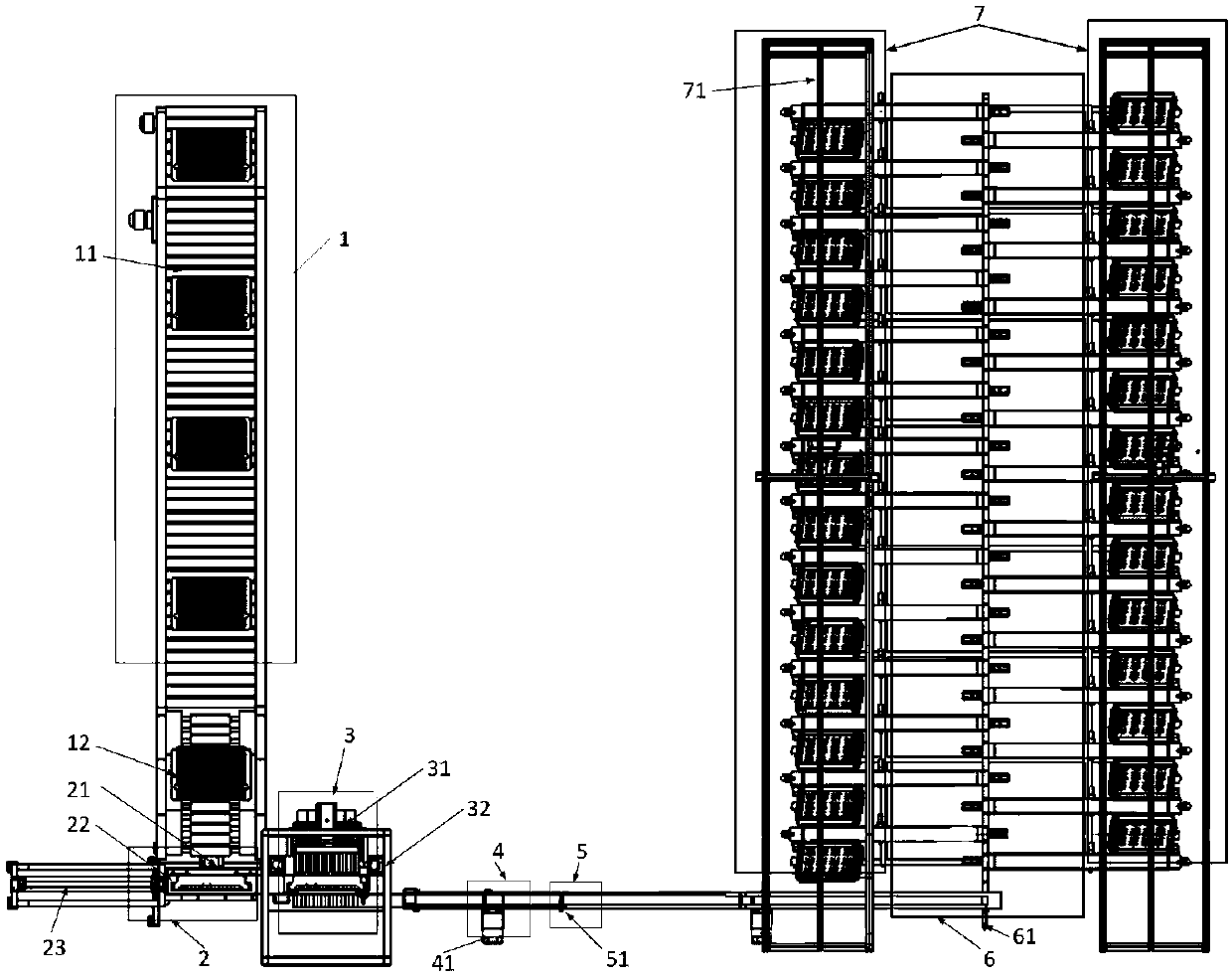

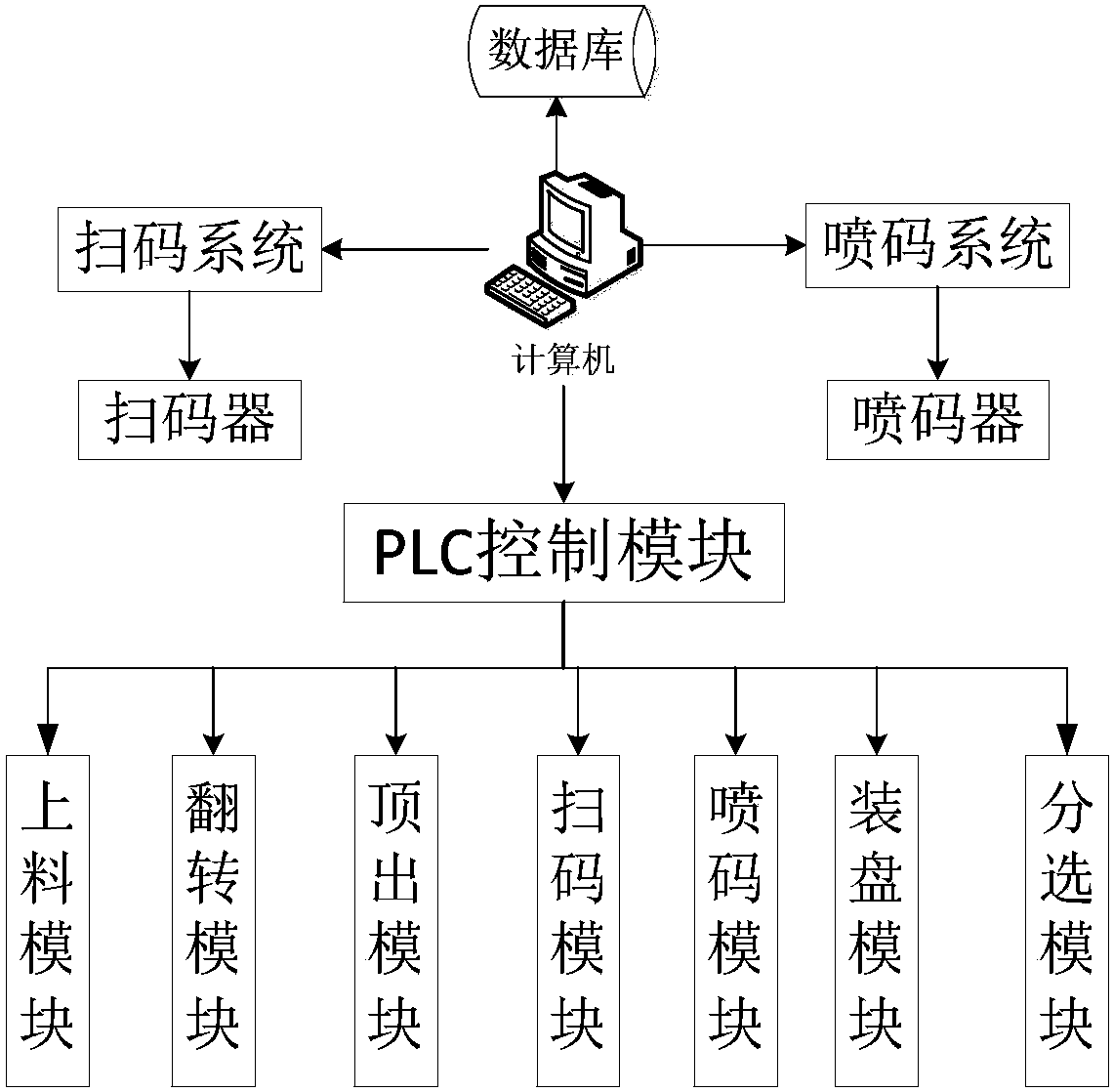

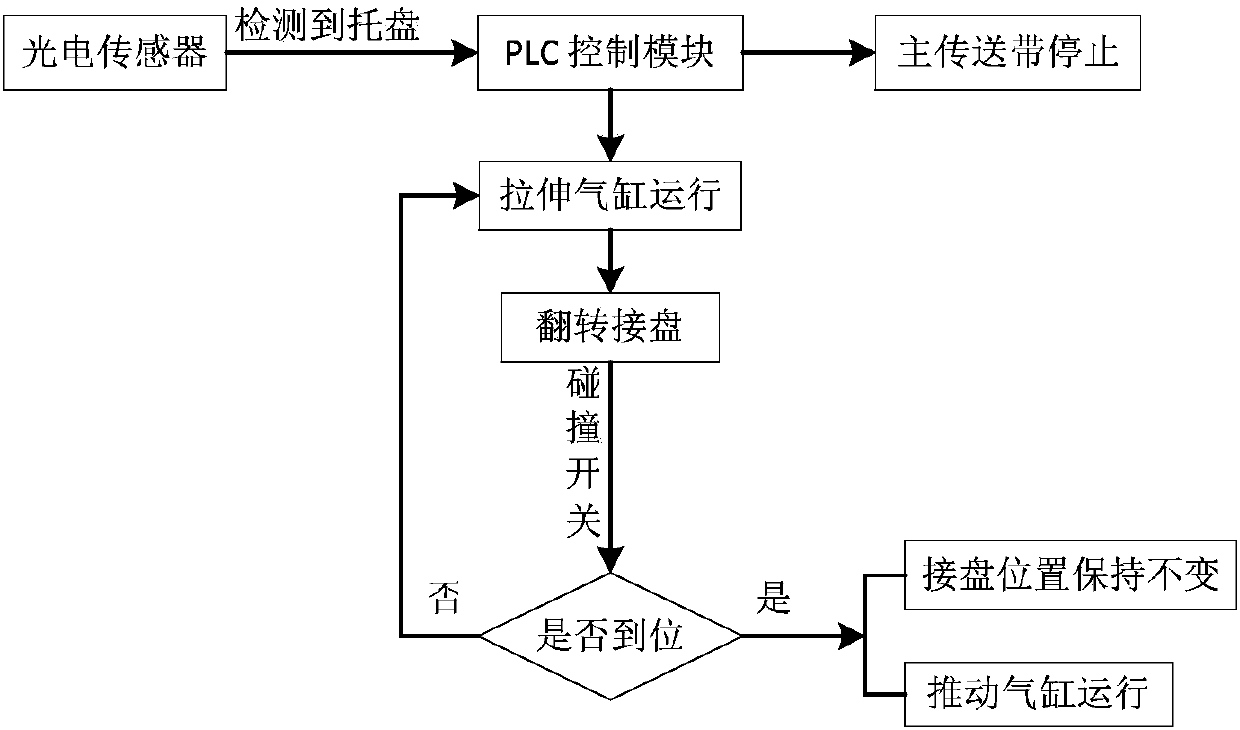

[0027] Such as figure 1 , 2 , 3, the pallet is manually placed on the main conveyor belt 11, the main conveyor belt 11 transmits the pallet to the flipping tray 22, after the photoelectric sensor 12 detects that the tray reaches the flipping tray 22, the signal is sent to the PLC control module, and the PLC control module passes The driver controls the motor to stop, and then controls the main conveyor belt 11 to stop running. At the same time, the PLC control module controls the stretching cylinder 21 through the pneumatic solenoid valve to drive the turning plate 22 to rotate upward. module, the PLC control module sends a stretching cylinder 21 holding signal to keep the position of the flipping plate unchanged. Then the PLC control module controls the push cylinder 23 to push the tray to the ejection module 3 through the pneumatic solenoid valve.

[0028] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com