Underground diaphragm wall joint section steel cleaning device and cleaning method

A technique for an underground diaphragm wall and a cleaning device, which is applied in the direction of cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., and can solve the problem of affecting the connection effect of underground diaphragm wall unit sections, cleaning cohesive soil, and poor cleaning effect Ideal and other issues, to achieve the effect of simple structure, improved connection quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

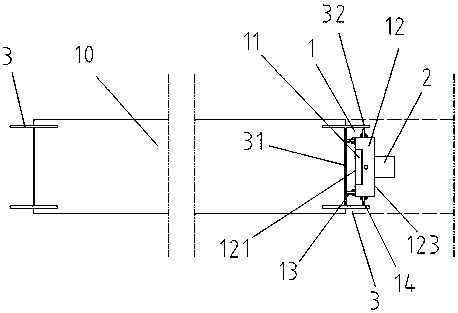

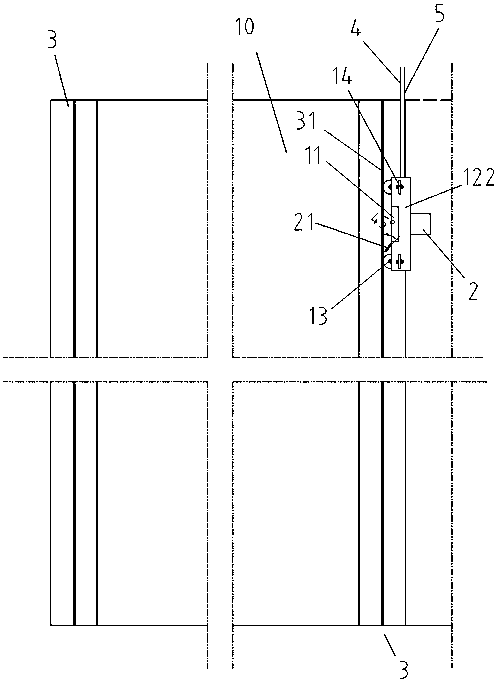

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] Such as figure 1 with figure 2 As shown, the device of the present invention comprises a vertical lifting trolley 1 and an underwater mud pump 2. The vertical lifting trolley 1 comprises an electromagnet 11, a vehicle body 12, 4 longitudinal wheels 13 and 4 transverse wheels 14, and the electromagnet 11 is fixed in the direction of the H On the middle part of the longitudinal bottom surface 121 of the section steel web 31, the electromagnetic attraction force of the electromagnet reaches 10-12kN, and the vertical lifting trolley 1 and the underwater mud pump 2 weighing 500 kg can be firmly erected in the notch of the H-section steel 3 , will not fall. The four longitudinal wheels 13 are divided into two rows and supported between the longitudinal bottom surface 11 of the vehicle body and the H-shaped steel web 31, and the four transverse wheels 14 are supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com