Aluminum warm forming multi-opening oven and production line

A technology of oven and outlet opening, applied in the field of oven components, can solve the problems of prolonging cycle time, heat loss, occupying floor space, etc., and achieving the effect of reducing cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

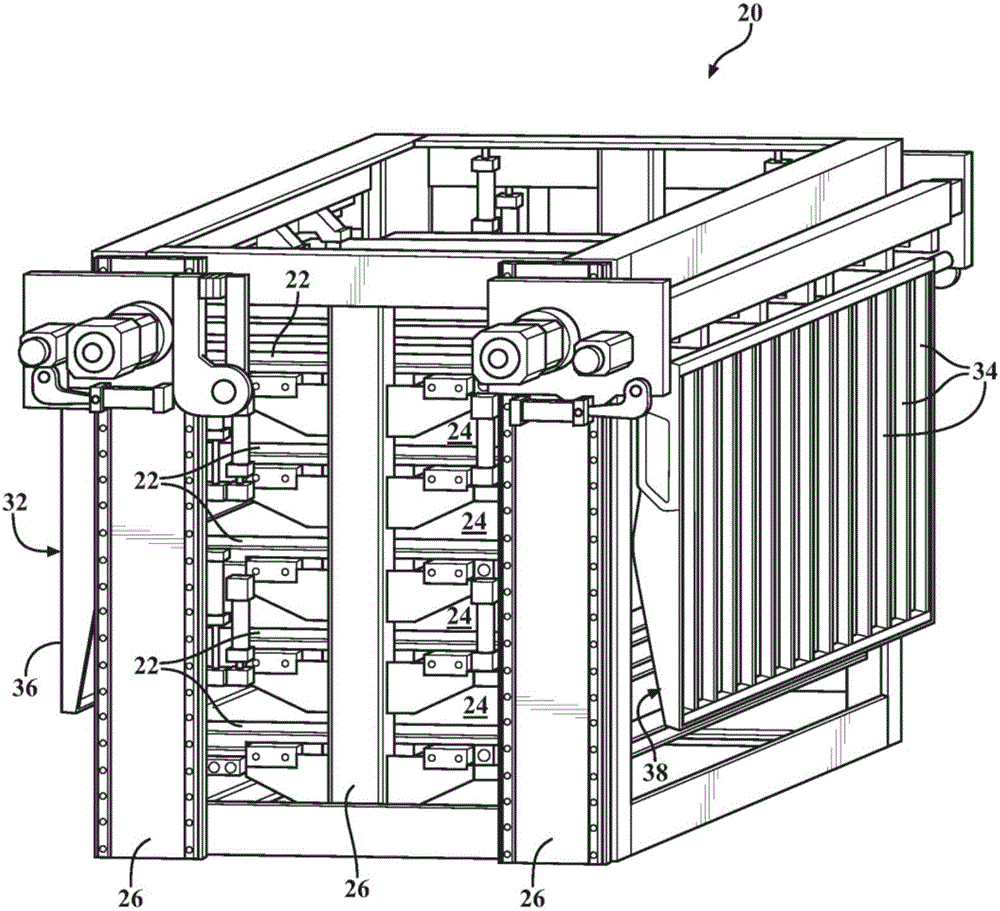

[0017] The present invention provides a multi-window oven assembly 20, which is used to simultaneously heat a plurality of metal blanks in a production line, as shown in Fig. 1 to Figure 5 shown in . The multi-window oven assembly 20 is typically used to heat multiple aluminum billets prior to warm or hot stamping, but the oven assembly 20 may alternatively be used in other types of metal forming processes. In one embodiment, the aluminum billet is formed from a 5xxx series aluminum alloy, although other alloys may also be used.

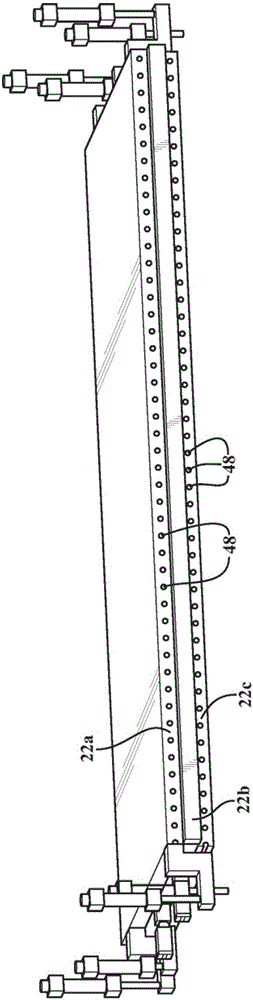

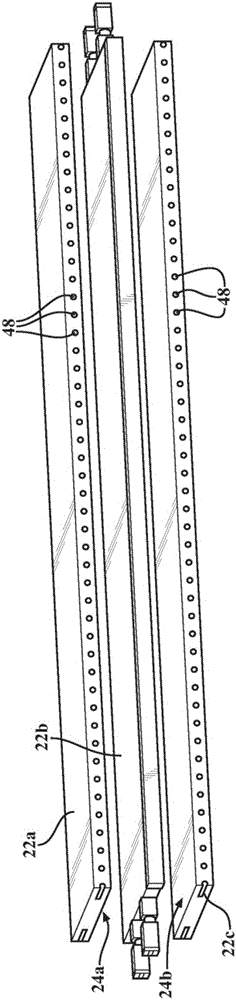

[0018] Such as Figure 1A As best shown in , the multi-window oven assembly 20 includes a plurality of shelves 22 extending horizontally relative to the floor. The shelves 22 are vertically aligned and stacked relative to each other, and the shelves 22 are spaced apart from each other to provide a plurality of vertically aligned heating chambers 24 . The number of shelves 22 and chambers 24 can be adjusted according to the desired throughput. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com