Automatic control device and method for through-feed grinding of centerless grinding machine

An automatic control device, centerless grinding machine technology, applied in the direction of grinding automatic control device, grinding drive device, abrasive surface adjustment device, etc. quality, improve processing efficiency, and reduce the effect of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

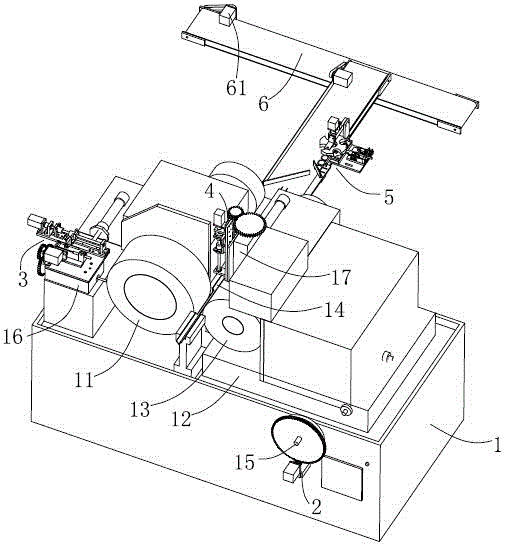

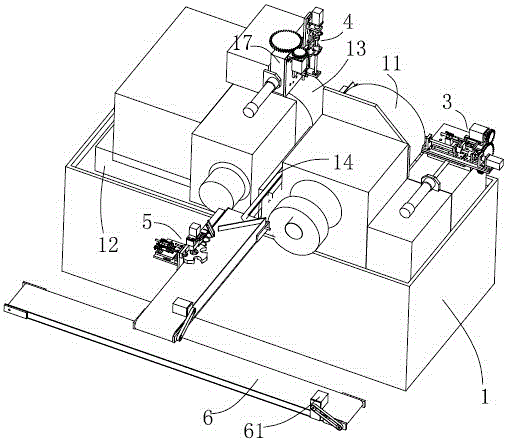

[0035] Embodiment: A centerless grinding machine through-grinding automatic control device (see figure 1 figure 2 ), including guide wheel frame feed compensation fine-tuning device 2 set on bed frame 1, grinding wheel correction value measurement feedback device 3, guide wheel correction value measurement feedback device 4 and online workpiece automatic measurement set on inspection conveyor belt 511 Feedback device 5, discharge and distribution conveyor belt 6 and automatic control system.

[0036] On-line workpiece automatic measuring and setting feedback device 5 (see Figure 6 Figure 7 ) includes the inspection mechanism that undertakes the centerless grinding export workpiece and submits it for inspection, and the measurement mechanism that measures the finished workpiece and feeds back to the automatic control system. The inspection mechanism includes an inspection conveyor belt 511 arranged on a plane on the inspection conveyor belt 511, an inspection oblique baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com