Production method for polyvinyl chloride sheet flooring

A production method and technology of stone-plastic panels, applied in the field of machinery, can solve problems such as high production costs, flattening and cutting of stone-plastic panels, and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

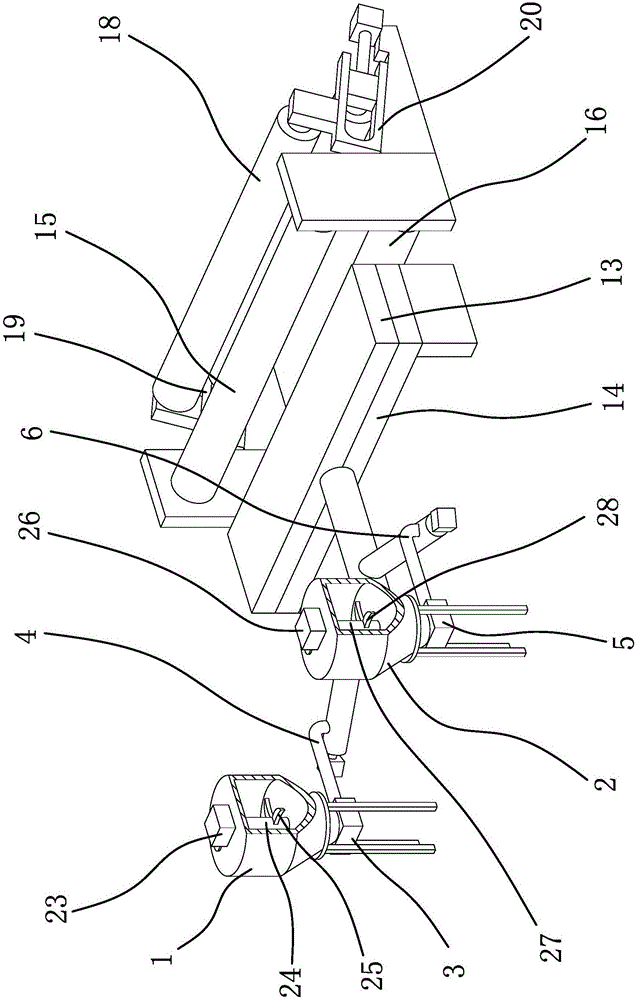

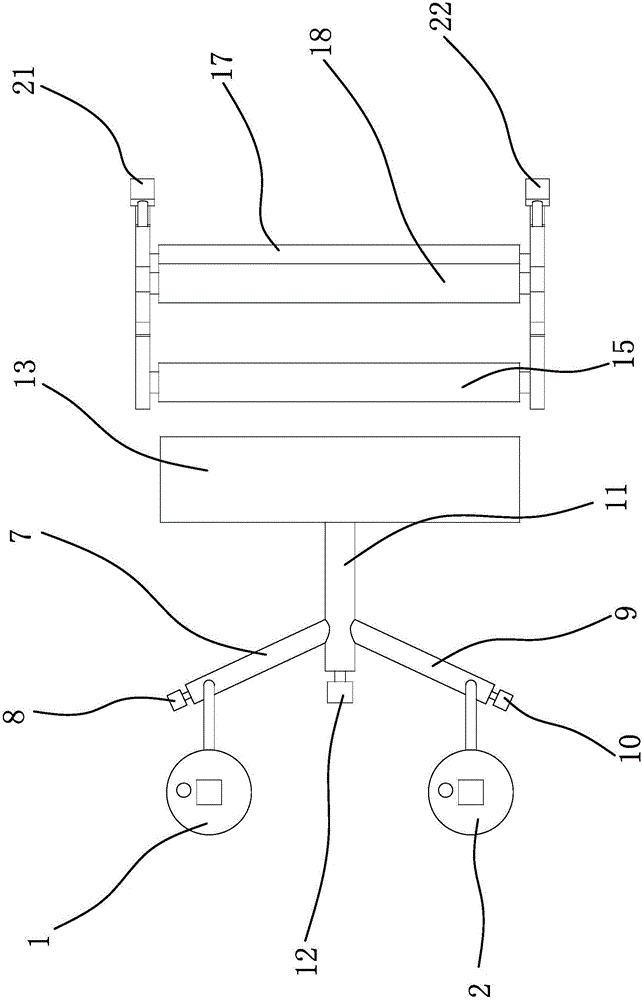

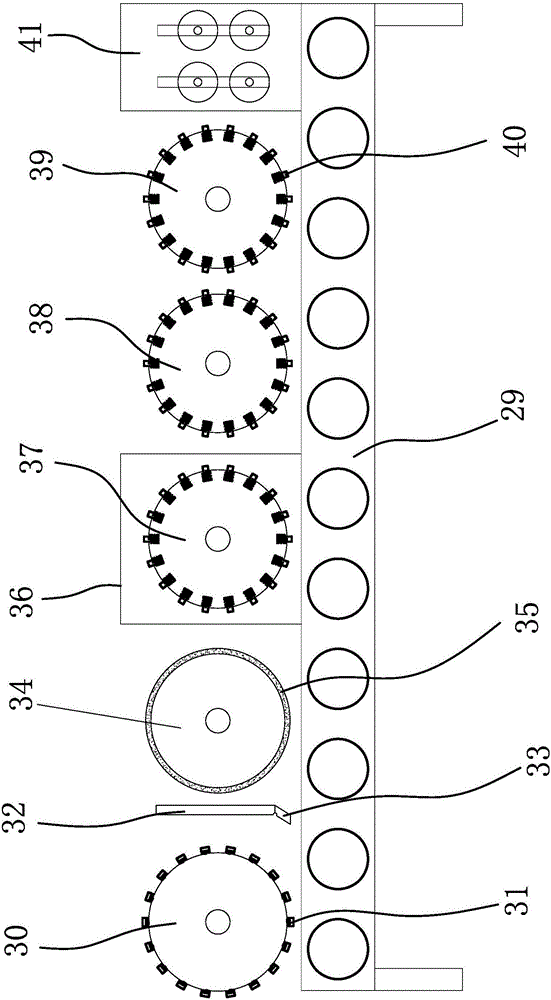

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0033] A method for producing a stone-plastic board, the method comprising the following steps: a, preparing raw materials for fabrics, preparing 300 kg of marble stone powder and 3-5 kg of paraffin wax; b, preparing raw materials for bottom material, preparing 320 kg of marble stone powder, 120 kg of One kilogram of polyvinyl chloride and 3-5 kilograms of paraffin; c, making stone-plastic board; d, surface treatment of stone-plastic board; the surface of stone-plastic board is treated by processing device, so that the surface of stone-plastic board has better wear resistance ;

[0034] Such as figure 1 As shown, the raw materials prepared in steps a and b are made of stone-plastic boards using manufacturing equipment. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com