Annular flow guide gate for ship

A kind of diversion grid and annular technology, which is applied in the field of marine annular diversion grid, which can solve the problems of optimal adjustment of the angle and position of the upflow, and the resistance of the duct.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

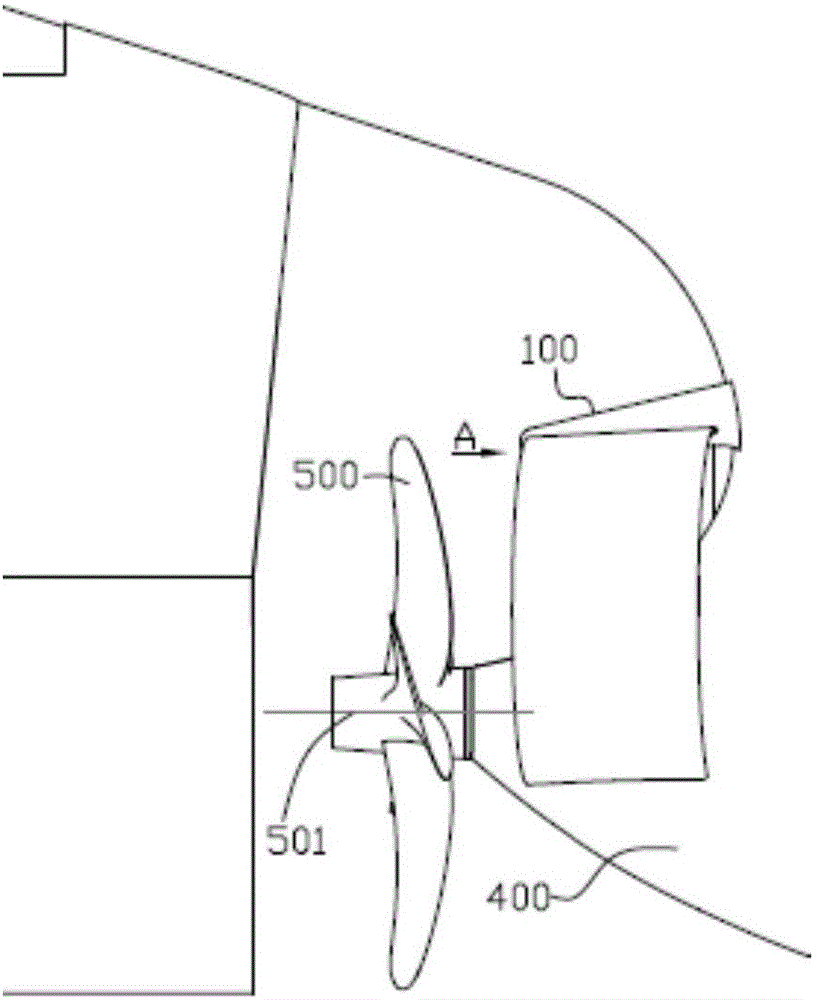

[0024] Example 1, such as figure 1 As shown, the device 100 of the present invention is fixedly installed in front of the propeller 500 and at the stern of the hull 400 , most of which are offset above the propeller shaft 501 .

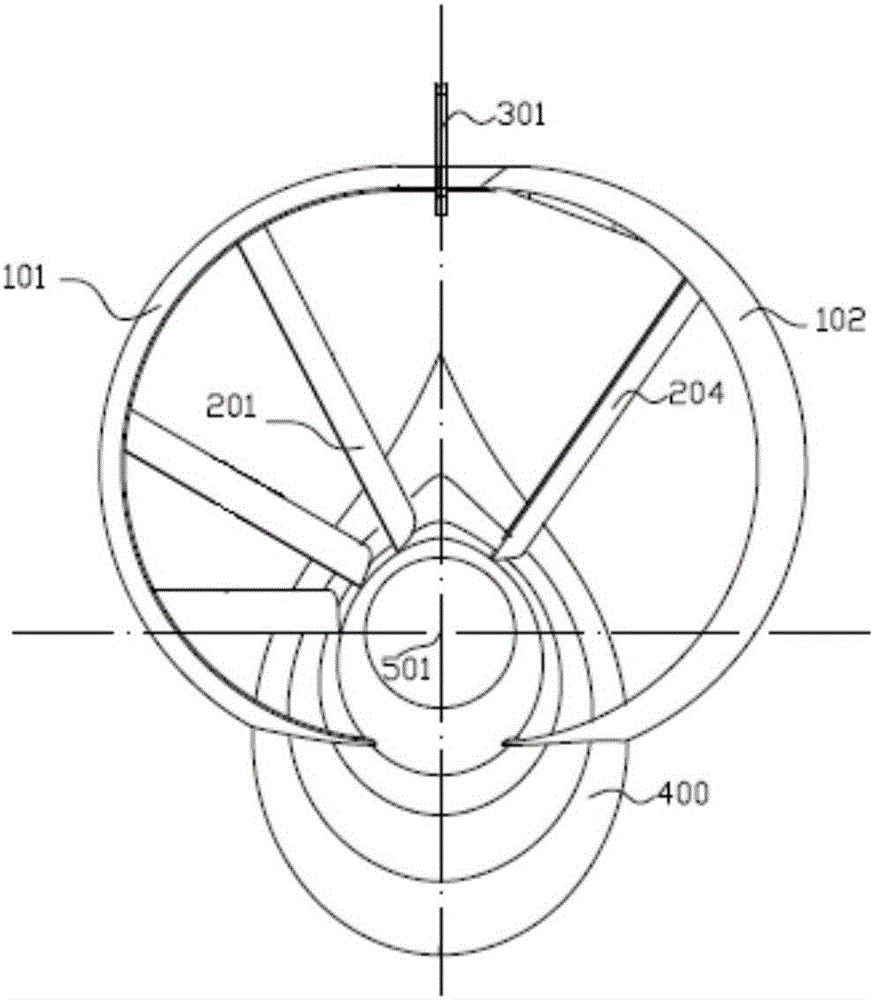

[0025] like figure 2 It is a detailed structural diagram of the present invention. The device 100 of the present invention comprises a port draft tube 101, a starboard draft tube 102, a port guide vane 201, a starboard guide vane 204 and a reinforcement structure 301, the lower ends of the port draft tube 101 and the starboard draft tube 102 are directly connected to the hull 400, The upper ends of the port draft tube 101 and the starboard draft tube 102 are connected through a reinforcement structure 301, and the reinforcement structure 301 is fixedly connected to the hull 400. They form an angle of 3° with each other in the horizontal direction. The quantity of the port guide vane 201 is determined according to the space inside the port guide va...

Embodiment 2

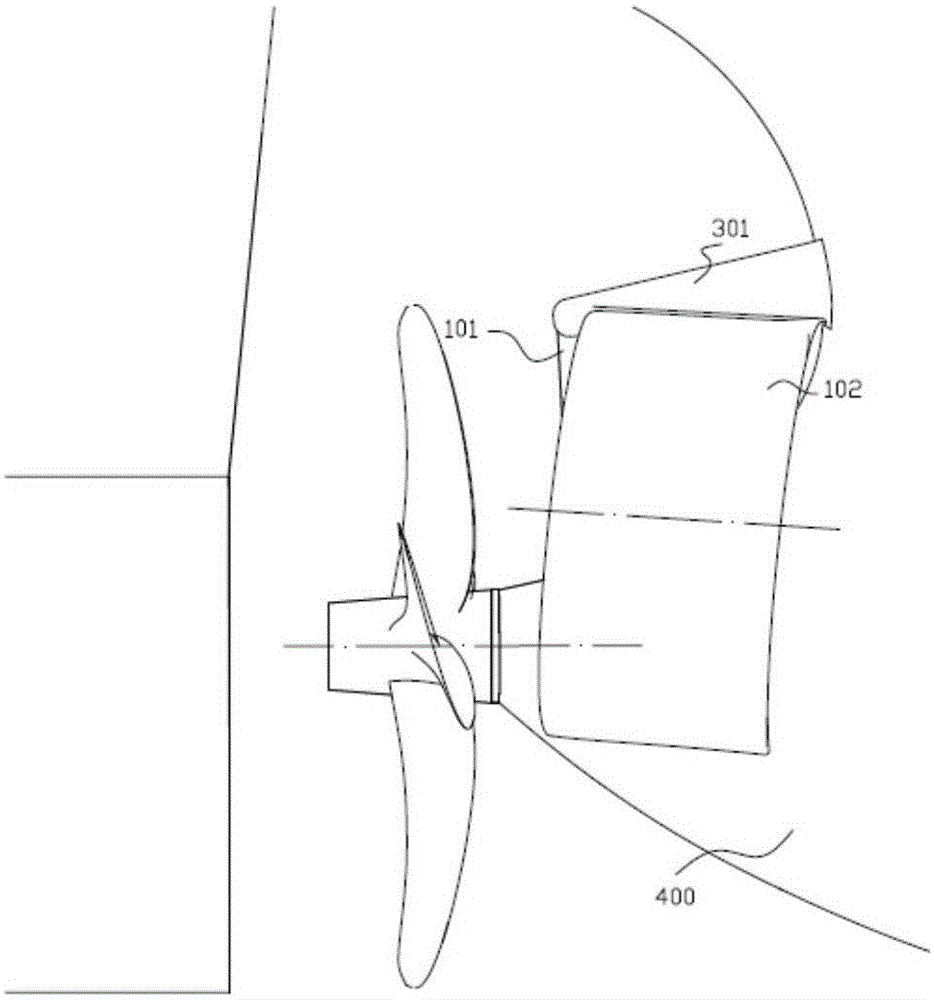

[0027] Example 2, such as image 3 Shown is another embodiment of the present invention. In this embodiment, the lengths of the port draft tube 101 and the starboard draft tube 102 are both 0.4 times the diameter of the propeller 500, and the diameters of the port draft tube 101 and the starboard draft tube 102 are both 0.6 times the diameter of the propeller 500. The port nozzle 101 has an inclination of -3° in the vertical plane, and the starboard nozzle 102 has an inclination of +3° in the vertical plane.

Embodiment 3

[0028] Example 3, such as Figure 4 As shown, the port draft tube 101 and the starboard draft tube 102 are semi-elliptical, the lengths of the port draft tube 101 and the starboard draft tube 102 are 0.25 times the diameter of the propeller 500, and the port draft tube 101 and the starboard draft tube The major axes of the flow tubes 102 are also 0.85 times the diameter of the propeller 500 . Wherein the long axis of the ellipse is along the up-down direction, and the short axis is along the horizontal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com