Shell with metal texture, manufacturing method of shell and electronic product

A technology of metallic texture and production method, applied in the direction of metal shell, metal material coating process, ion implantation plating, etc., can solve the problems of complex process, high processing cost, low yield rate, etc. Material cost, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

[0021] The concept of the present invention is: through a certain process, such as activation, sensitization process, plasma impact metal target material, metal coating, etc. in a vacuum environment, so that the surface of some non-metallic materials also has a metallic texture, not only metal can be used as an anodic oxidation substrate , Plastic, glass, ceramics, silicone rubber, etc. can all be anodized, and the anodized layer is attached to the coating layer, rather than directly attached to the surface of the substrate. In this way, the material selectivity of the base material is increased when making the shell product, thereby effectively reducing the material cost.

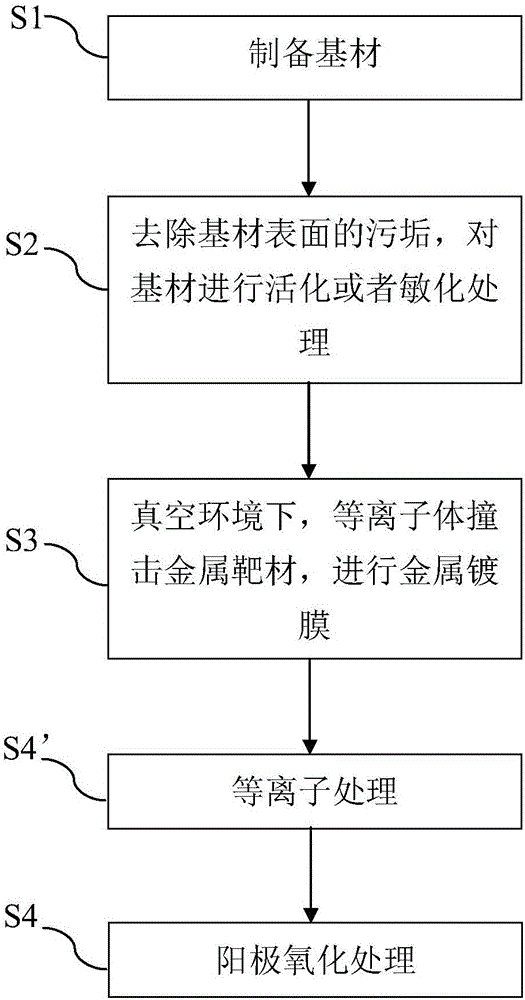

[0022] Such as figure 1 As shown, it is a flow chart of the manufacturing method of the metal-feeling shell in this specific embodiment. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com