Parallel operation type quick tunneling support system and construction method

A parallel operation and operation technology, which is applied in the direction of earth drilling, mine roof support, mining equipment, etc., can solve the problems that the parallel operation of tunneling and bolt support cannot be realized, and reduce the efficiency of coal mining, so as to improve the efficiency of coal mining, The supporting effect is better and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

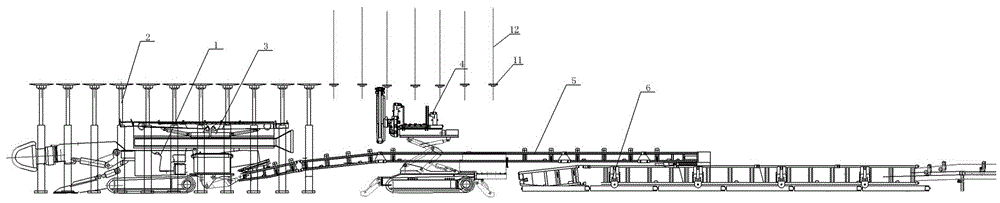

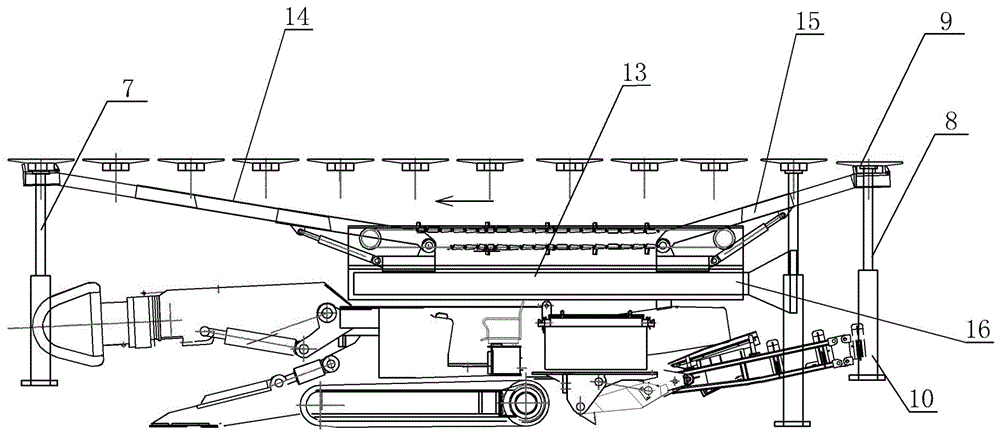

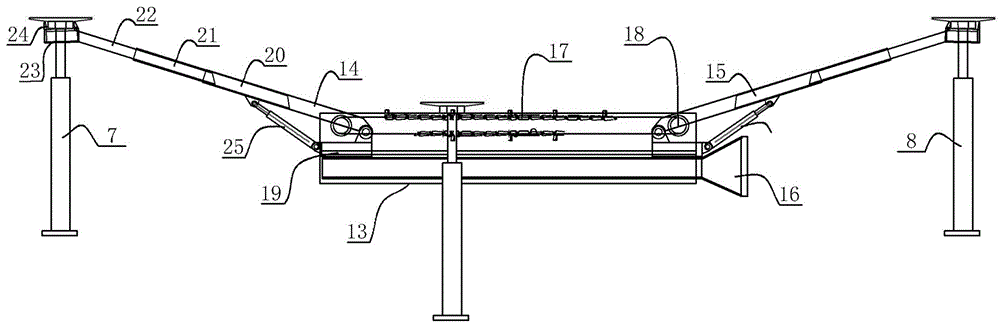

[0022] Such as figure 1 As shown, a schematic structural view of the parallel operation type fast driving support system of the present invention is provided, which consists of a roadheader 1, a support frame 2, a transport device 3, a bolting drilling rig 4, a front end conveyor 5, and a self-moving machine The tail type conveyor 6 is composed of the roadheader 1 shown for mining coal mines, and the front end transport vehicle 5 is located at the rear end of the roadheader 1 for transporting out the coal mines mined by the roadheader 1 . Self-moving machine tail conveyor 6 is arranged on the rear end of the front conveyor, and is used to further transport coal mines out. The support frame 2 is in the shape of a gantry, and is arranged at equal intervals on the periphery of the boring machine 1 to realize temporary support. The support frame 2 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com