Ignition control method for spark ignition type free piston linear generators

A linear generator, ignition control technology, applied in the direction of automatic control, automatic control, electrical automatic control, etc., can solve the problems of ignition-type free-piston linear generator shutdown, shutdown, internal combustion engine output power drop, etc., to achieve the ignition control method simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

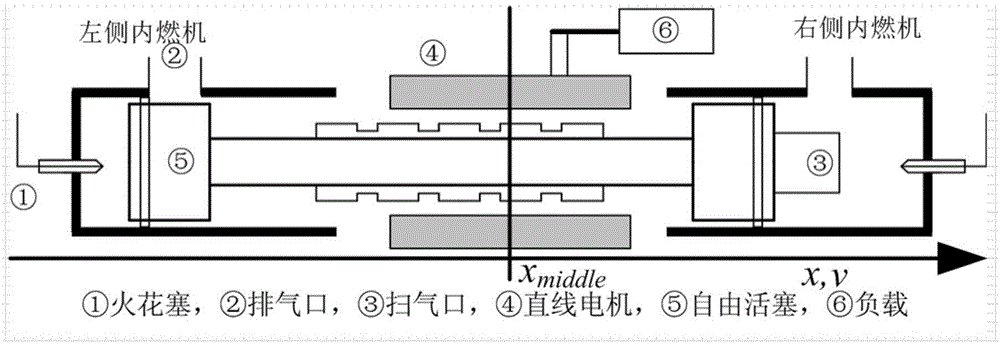

[0023] The ignition-type free-piston linear generator described in this embodiment is formed by coupling two free-piston internal combustion engines and a linear motor. Two free-piston internal combustion engines are symmetrically arranged on the left and right sides of the linear motor. The two free-piston internal combustion engines are respectively defined as a left internal combustion engine and a right internal combustion engine. Its working principle is that the mixed gas in the left and right cylinders of the internal combustion engine is alternately ignited and burned to generate high-temperature and high-pressure gas to push the piston and the motor mover to reciprocate, cut the magnetic field lines, generate electrical energy, and directly convert the chemical energy of the fuel into electrical energy. Such as figure 1 shown.

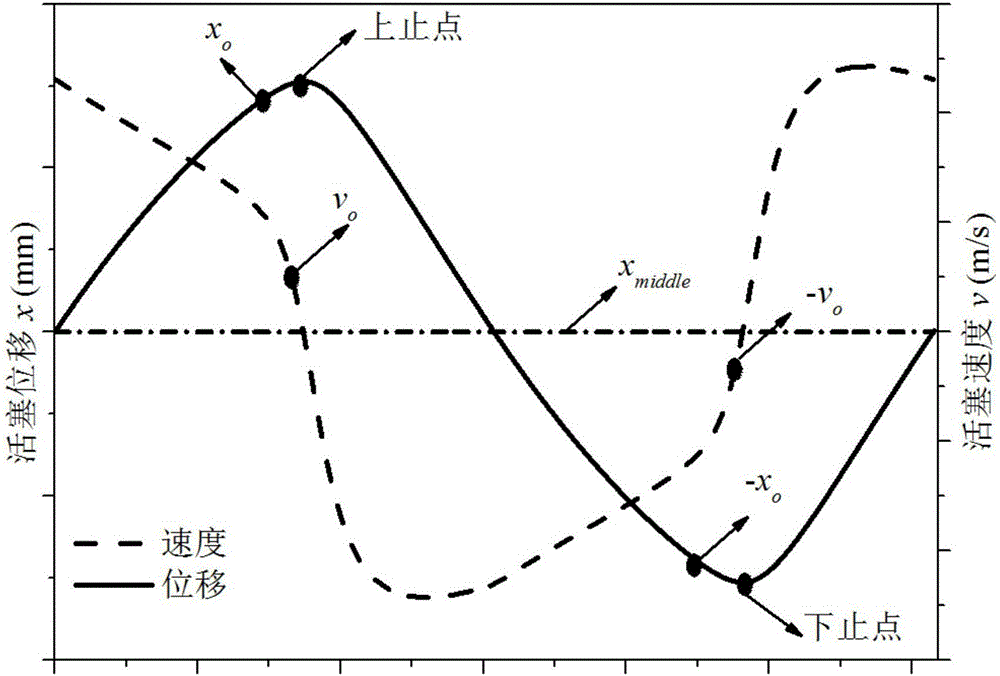

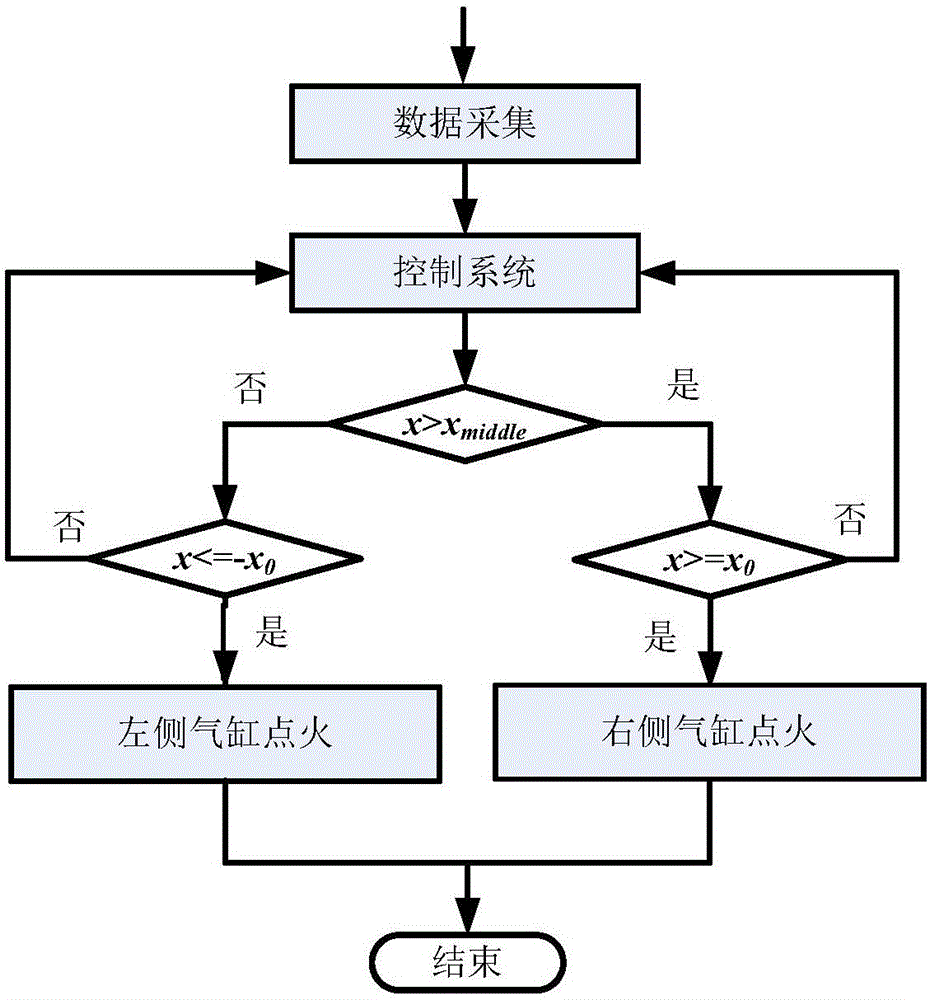

[0024] An ignition control method for an ignition-type free-piston linear generator disclosed in this embodiment includes the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com