Low-speed large-torque downhole hydraulic motor and operating method thereof

A low-speed, high-torque, hydraulic motor technology, applied in the direction of drilling equipment, earthwork drilling, fluid pressure actuators, etc., can solve the problems of cumbersome maintenance, long maintenance cycle, limited tool application, etc., and achieve low protection requirements for storage and transportation , reduce the probability of stuck pipe, and prevent the effect of accidental well drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

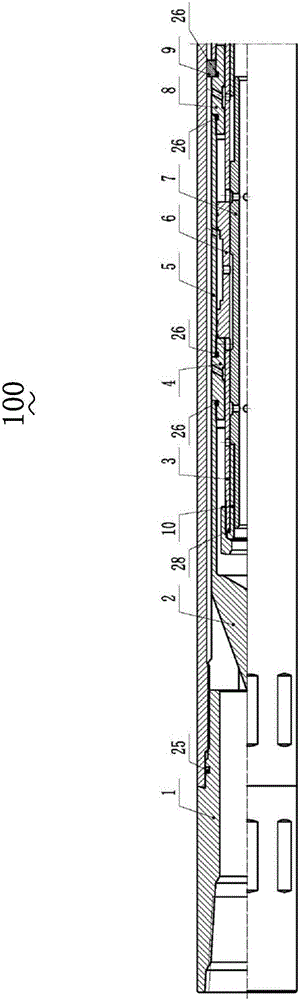

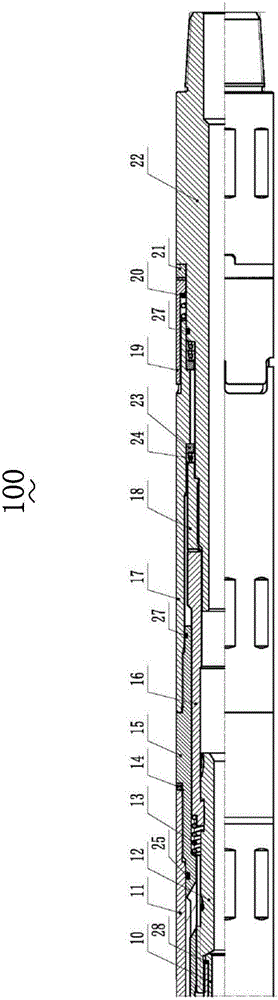

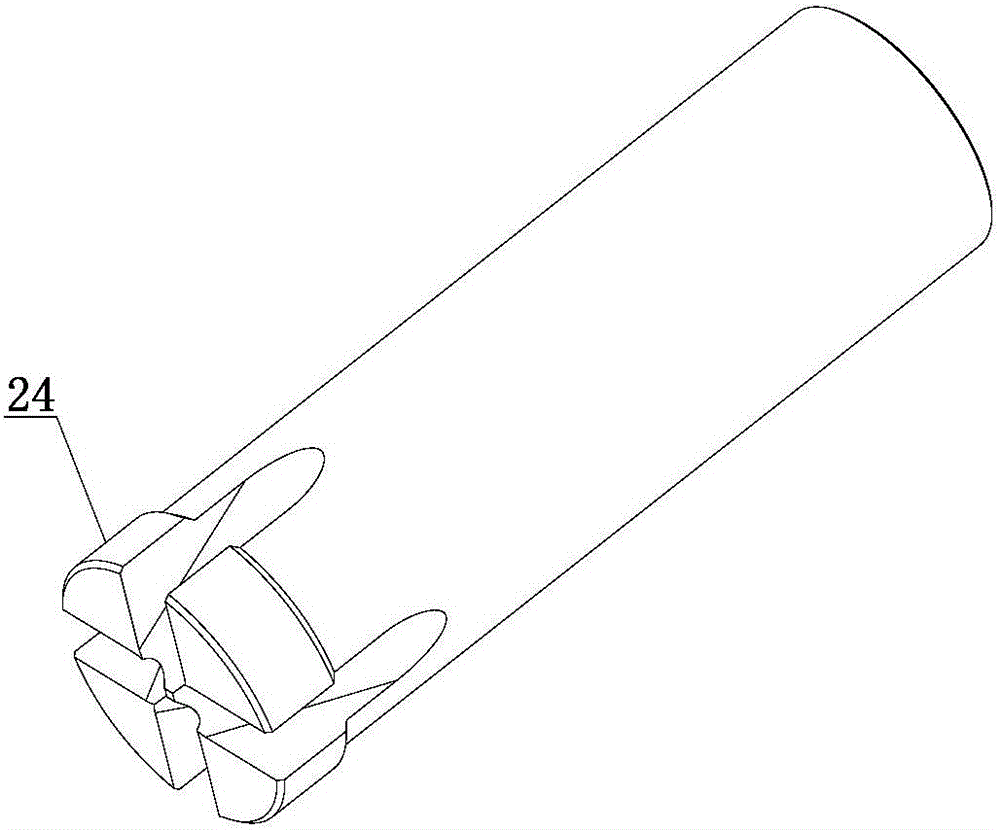

[0045] Please refer to Figure 1 to Figure 8 , the low-speed high-torque downhole hydraulic motor 100 includes a flow distribution assembly, an axial reciprocating drive assembly, an axial rotation conversion assembly, and an anti-rotation assembly.

[0046] The distribution assembly includes a flow guide sleeve 2, an outer cylinder 11, and a flow distribution plate 9, and the flow distribution plate 9 controls the throttling pressure.

[0047] The axial reciprocating drive always includes an upper valve body 4 , a valve body 5 , a lower valve body 8 , an impact valve 6 and a reversing valve 7 .

[0048] The lower valve body 8 is provided with a liquid inlet hole 25 , and the upper valve body 4 , valve body 5 , impact valve 6 , reversing valve 7 and lower valve body 8 are sequentially connected and arranged in the outer cylinder 11 .

[0049]The axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com