A multi-stroke cylinder

A multi-stroke, cylinder technology, applied in the direction of fluid pressure actuation device, servo meter circuit, mechanical equipment, etc., can solve the problems of high sealing requirements, high cost of multi-stroke cylinder, complex control system, etc., to achieve a simple appearance Beautiful appearance, cost reduction, low assembly and machining accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

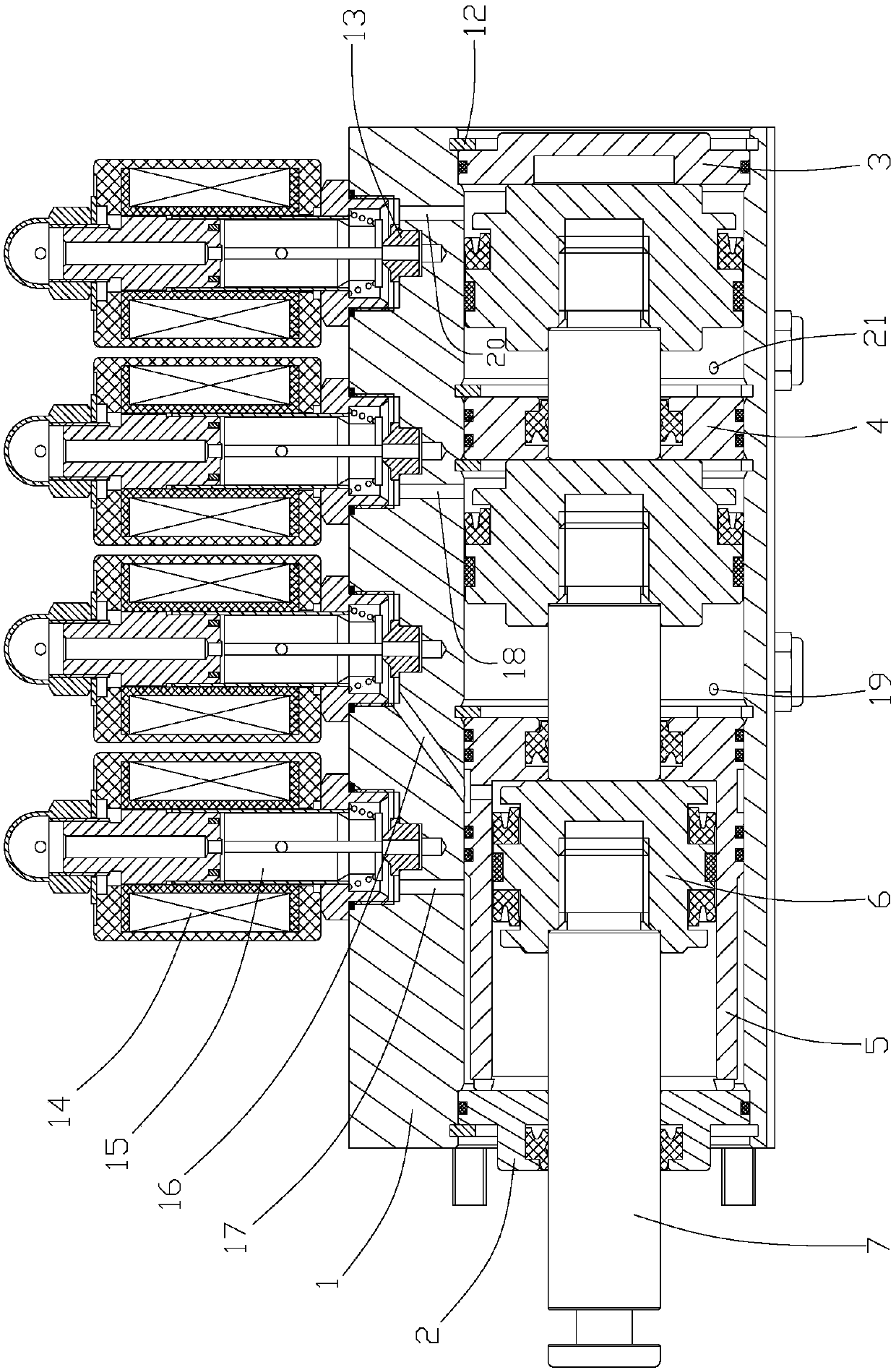

[0021] Implementation mode 1, see Figure 1-4 , a multi-stroke cylinder, including a cylinder 1, the cylinder 1 is provided with a tie rod according to the installation requirements, the two ends of the cylinder 1 are respectively provided with a front cover 2 and a rear cover 3, and the front cover 2 and the rear cover 3 pass through the holes respectively. The circlip 12 is fixed, and the cylinder 1 is provided with three piston chambers, which are respectively the first piston chamber, the second piston chamber and the third piston chamber, and the first piston chamber and the second piston chamber are separated by the cylinder liner 5, The function of the cylinder liner 5 is to change the diameter of the first piston chamber, thereby changing the thrust of the piston rod 7, the second piston chamber and the third piston chamber are separated by the middle cover 4, and the inner wall of the cylinder barrel 1 is provided with a number of annular slots, A circlip 12 for the h...

Embodiment approach 2

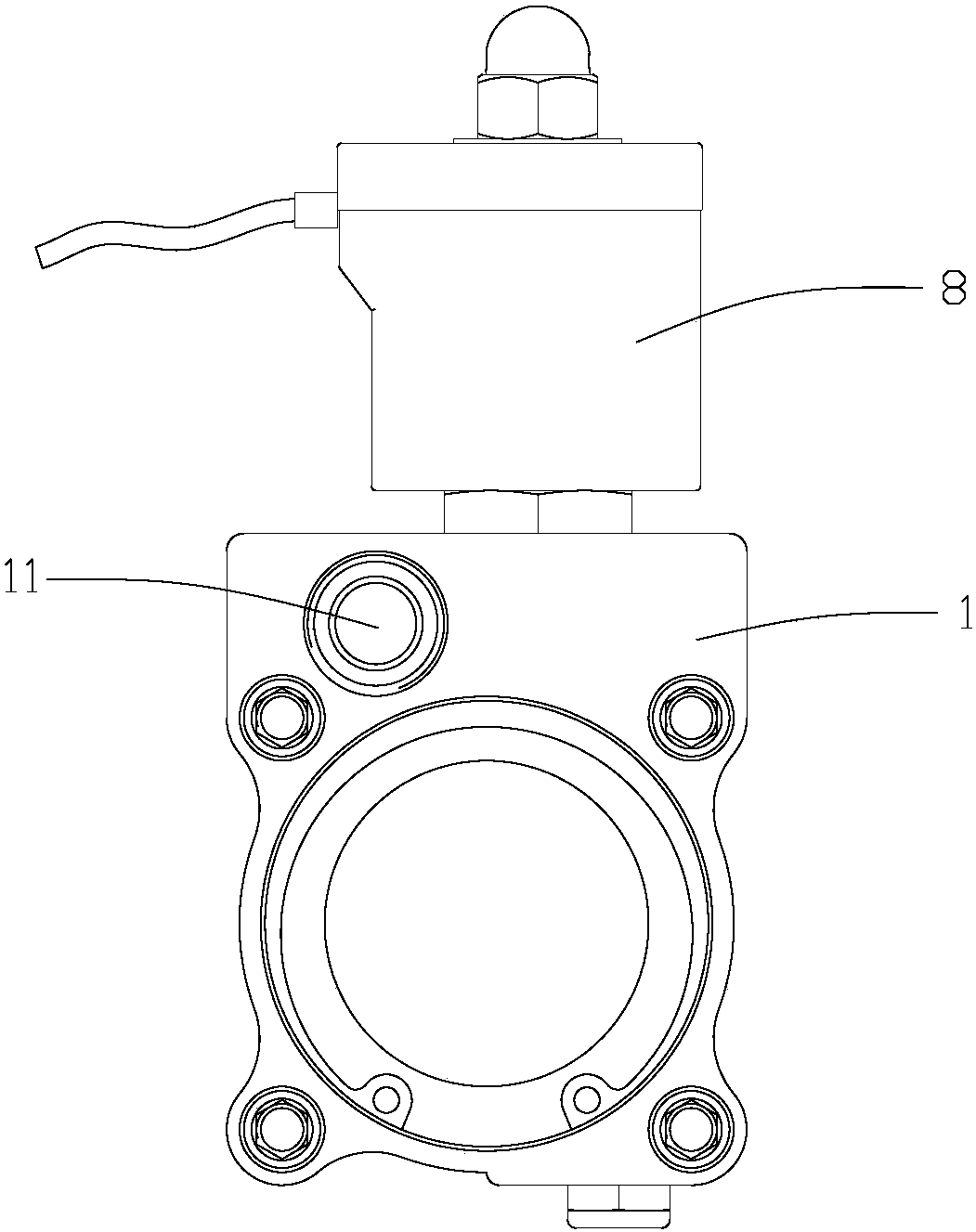

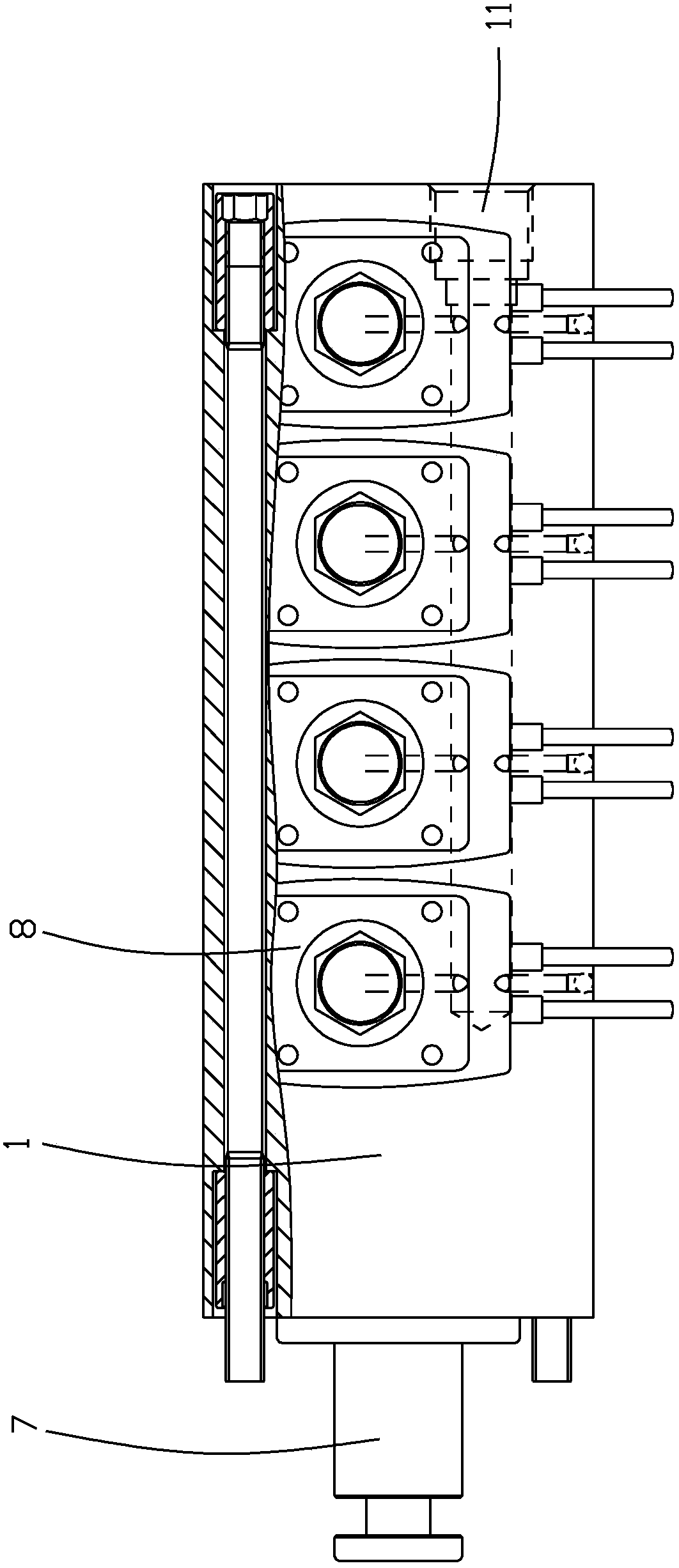

[0026] Implementation mode 2, see Figure 5 , the difference between this embodiment and Embodiment 1 is that: the first piston chamber, the second piston chamber and the third piston chamber are arranged in the cylinder barrel 1, and the first air inlet communicating with the first piston chamber is arranged on the cylinder barrel 1 The hole 16 and the first exhaust hole 17, the second air intake hole 18 and the second exhaust hole 19 communicating with the second piston chamber, and the third air intake hole 20 and the third exhaust hole corresponding to the third piston chamber 21. Six electromagnetic coil assemblies 8 are provided on the upper end of the cylinder 1, and the valve cavities of the six electromagnetic coil assemblies 8 are respectively connected with the first air inlet 16, the first air outlet 17, the second air inlet 18, the second air inlet The second exhaust hole 19 , the third air intake hole 20 and the third exhaust hole 21 communicate with each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com