Multi-blade capacitive angular displacement sensor

An angular displacement sensor, capacitive technology, applied in the sensor field, can solve the problems of sensitive electromagnetic environment, complex processing accuracy and demodulation circuit, limited ability to obtain angular displacement information, etc., achieve excellent mechanical and physical pollution, easy to promote and mutual. Replacement, good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

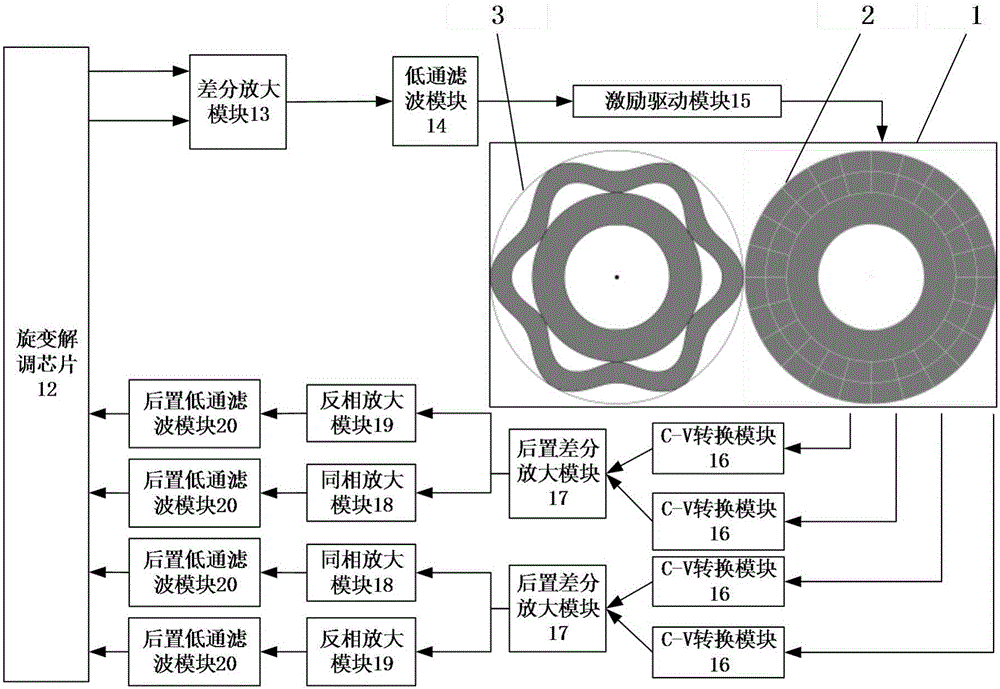

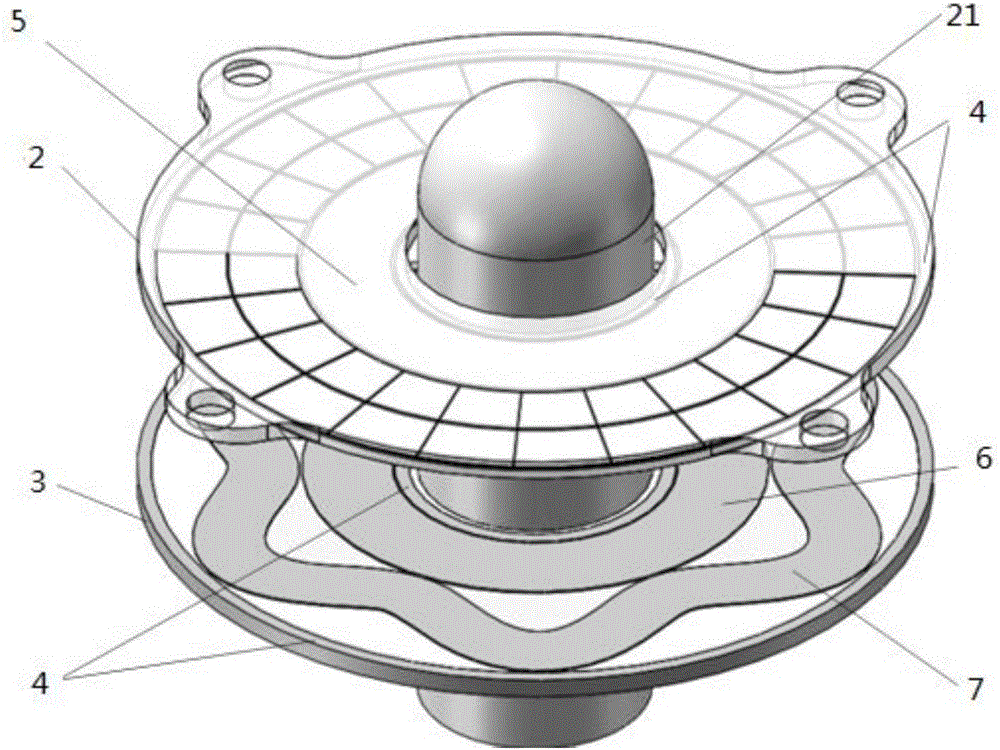

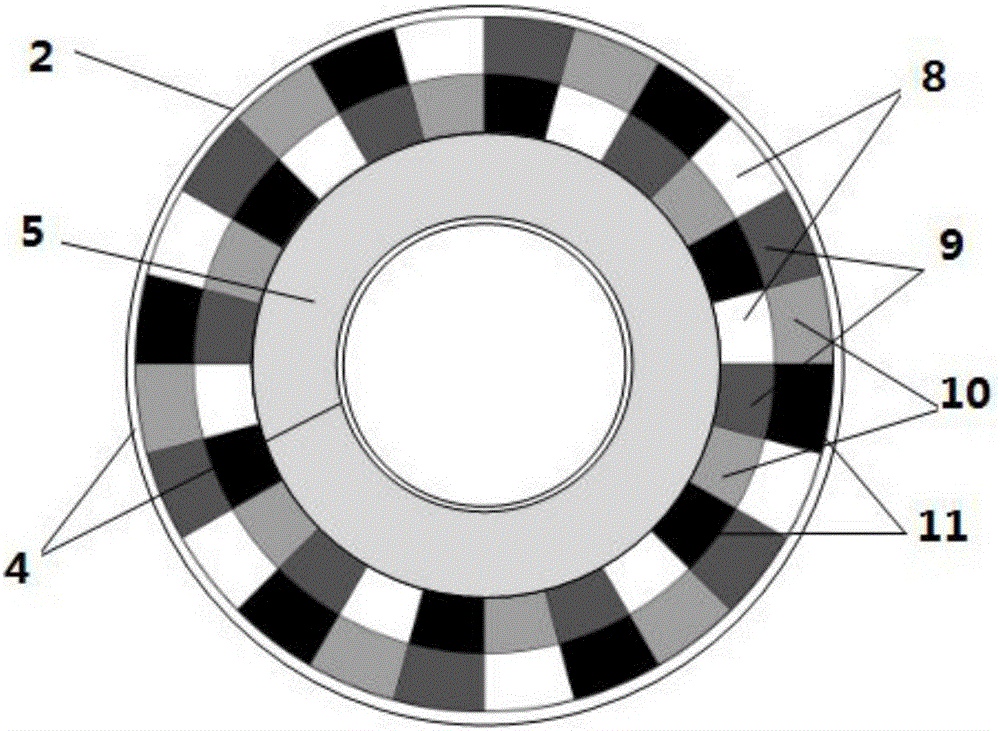

[0024] Such as Figure 1 to Figure 4 As shown, the present invention provides a split capacitive angular displacement sensor, which includes a demodulation circuit and a sensitive structure 1, the demodulation circuit generates a sinusoidal excitation signal to act on the sensitive structure 1, and the sensitive structure 1 returns capacitance change information to the solution Adjust the circuit to obtain the corner information. The sensitive structure 1 includes a stator 2 and a rotor 3, the stator 2 and the rotor 3 are coaxially arranged in parallel, and the protection electrode 4, the excitation electrode 5 and the collection electrode are arranged on the surface of the stator 2; The ring-shaped guard electrode 4 is used to eliminate the edge effect of the plate capacitance. A ring-shaped excitation electrode 5 is arranged on the outer side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com