Vision auxiliary sheet material excess material stock layout method

A technology for plates and surplus materials, applied in measuring devices, instruments, optical devices, etc., can solve problems such as misjudgment, inability to utilize plates, and low efficiency, so as to reduce waste of surplus materials and material costs, and strengthen management and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below according to the accompanying drawings.

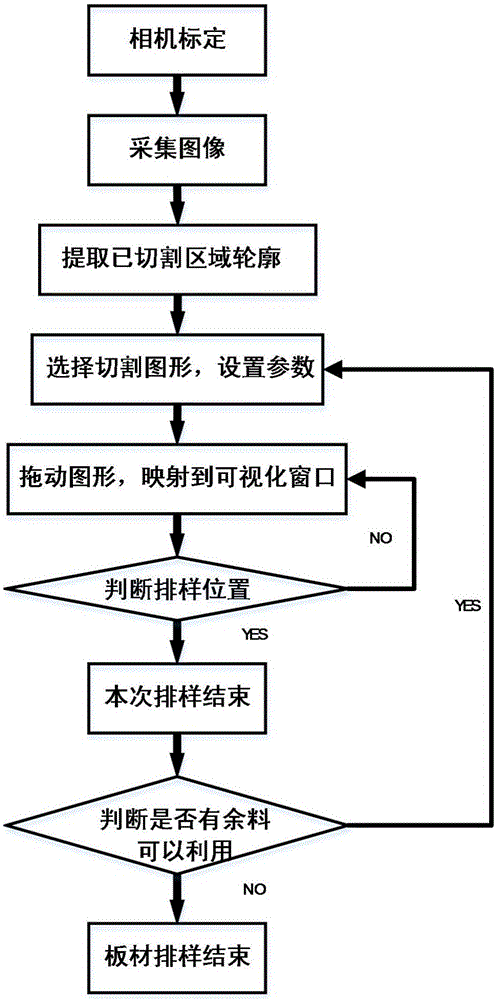

[0021] Such as figure 1 As shown, when the present invention is used, the light source is installed directly above the machine tool, and the 2D camera is fixedly installed on the upper left of the machine tool. After installation, the camera needs to be calibrated when it is used for the first time. The main purpose of calibration is to determine the image Each pixel value in corresponds to the distance of the actual machine tool, so as to determine the conversion relationship between the world coordinates of the plate plane and the pixel coordinates of the picture.

[0022] In the subsequent use, the camera collects images of the plate, and then transmits the photos to the computer, uses computer vision algorithms to process the image, extracts the shape and position information of the remaining material of the plate, and generates a visualized image window. In actual opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com