Simulated Vibration Roller Forming Machine for Asphalt Mixture Specimen and Method for Making Specimen

A kind of technology of asphalt mixture and vibrating wheel, which is applied in the direction of ceramic molding machine, test sample preparation, manufacturing tools, etc., can solve the problem that the vibration compaction process of steel wheel roller cannot be simulated, and achieve convenient steel wheel vibration wheel forming , low input cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

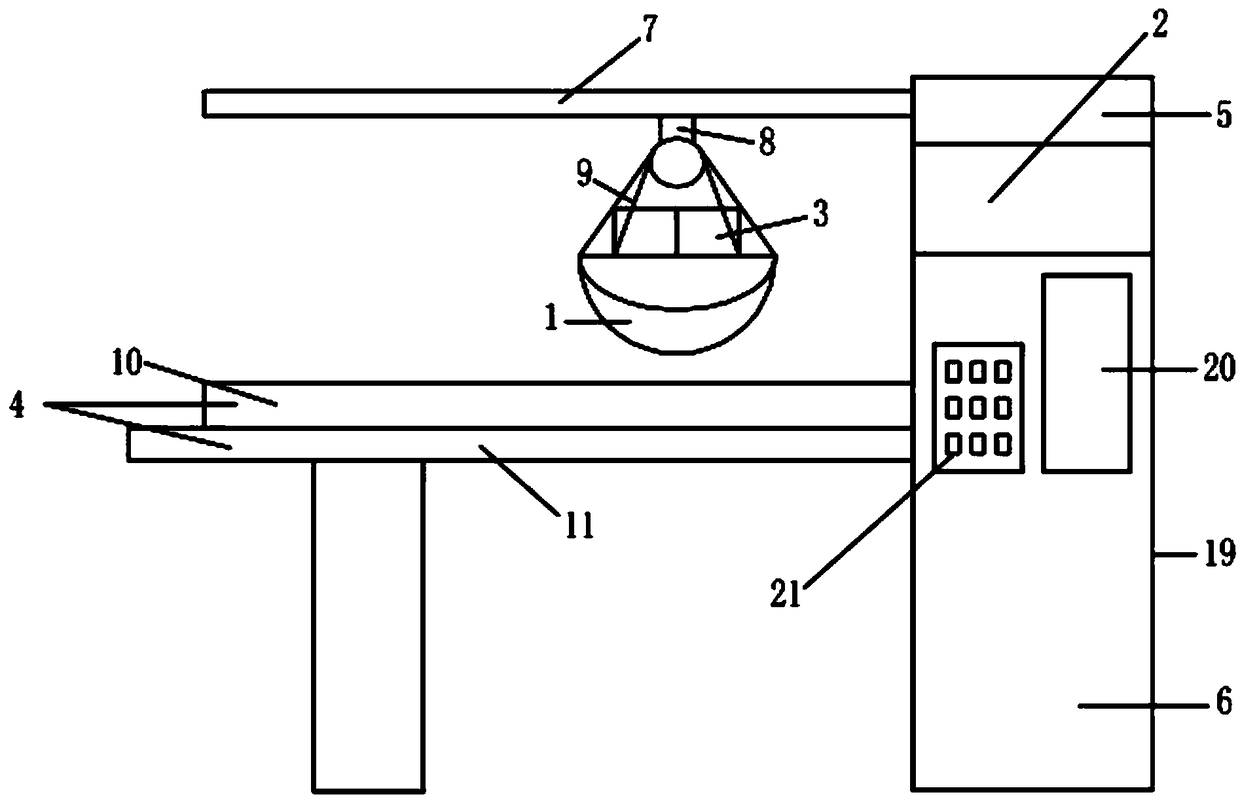

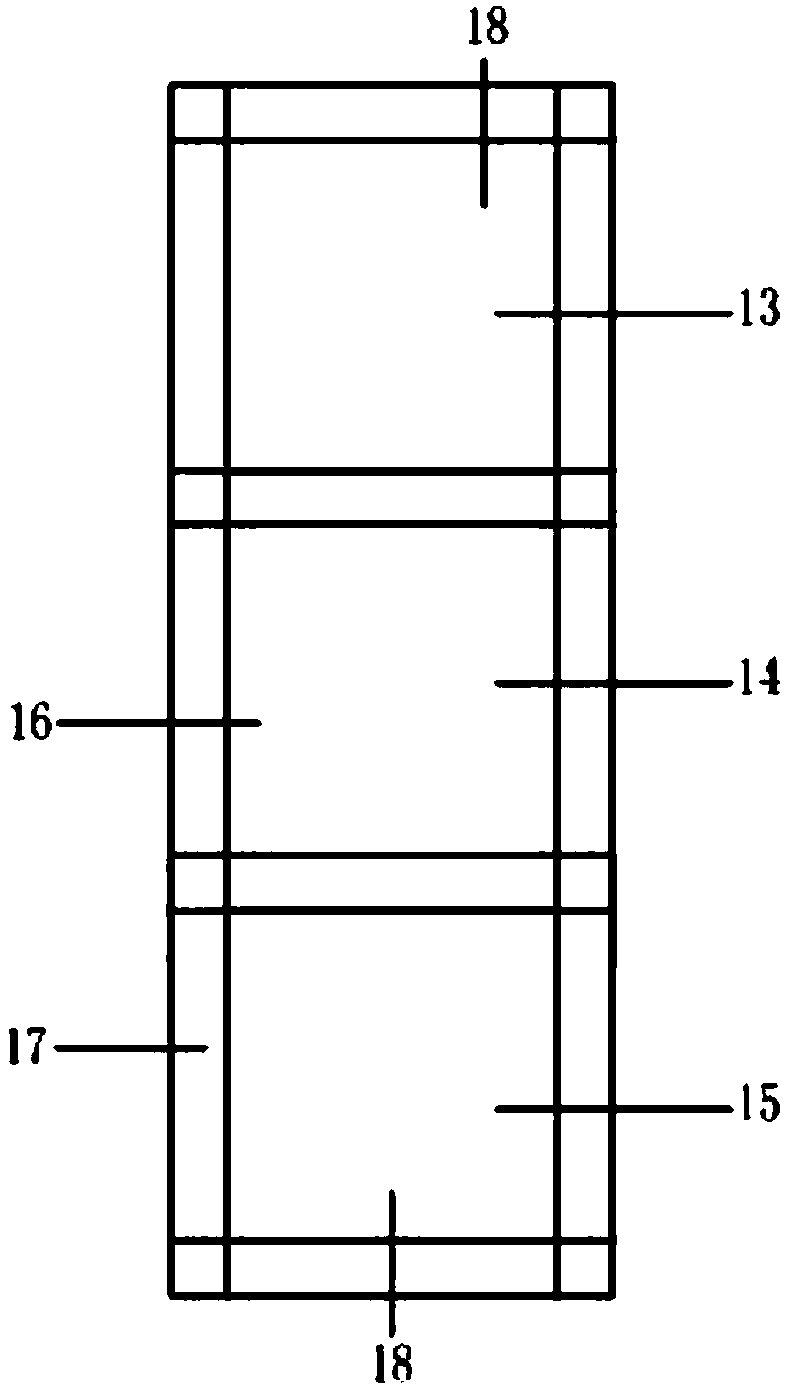

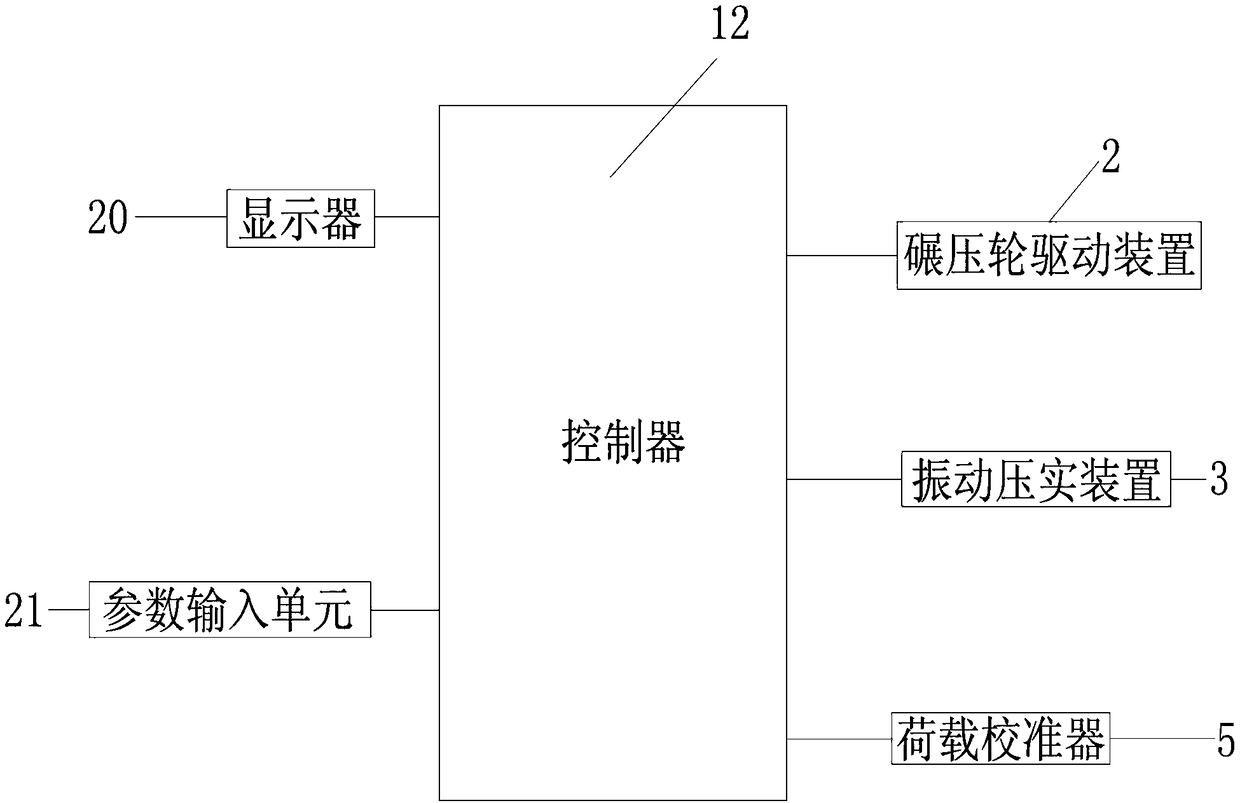

[0030] Such as Figure 1 ~ Figure 3 As shown in the figure, a simulated vibrating wheel roller molding machine for asphalt mixture specimens, including rolling wheel 1, rolling wheel driving device 2, vibration compacting device 3, sample support device 4, load frame 7, frame 9 And the control box 6, the rolling wheel driving device 2 is arranged on the control box 6, the load frame 7 is connected and fixed with the control box 6, the hydraulic dowel bar 8 is installed in the load frame 7, the rolling wheel driving device 2 and the hydraulic force transmission Rod 8 is connected with power, and rolling wheel 1 is connected with the outer wall of hydraulic dowel bar 8 through frame 9. The outer chord length of rolling wheel 1 in this embodiment is 30cm. The rolling wheel 1 is dynamically connected to the hydraulic pressure loading rod of the hydraulic dowel bar 8, and the rolling wheel driving device 2 is used to drive the hydraulic dowel bar 8 to drive the frame and the rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com