Autonomous heating type atomizer

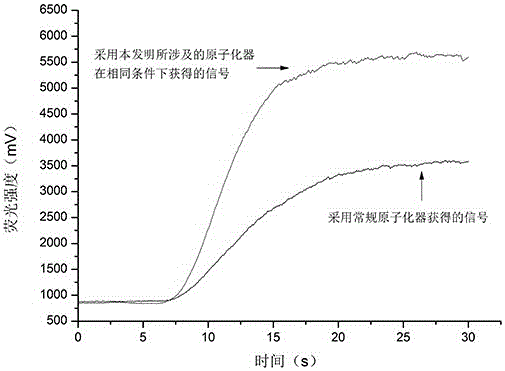

An atomizer and heating technology, used in instruments, scientific instruments, measuring devices, etc., can solve problems such as gradients, increased temperature gradients, large structures, etc., to reduce the probability of being broken and the speed of oxidation. The effect of slowing down and many processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

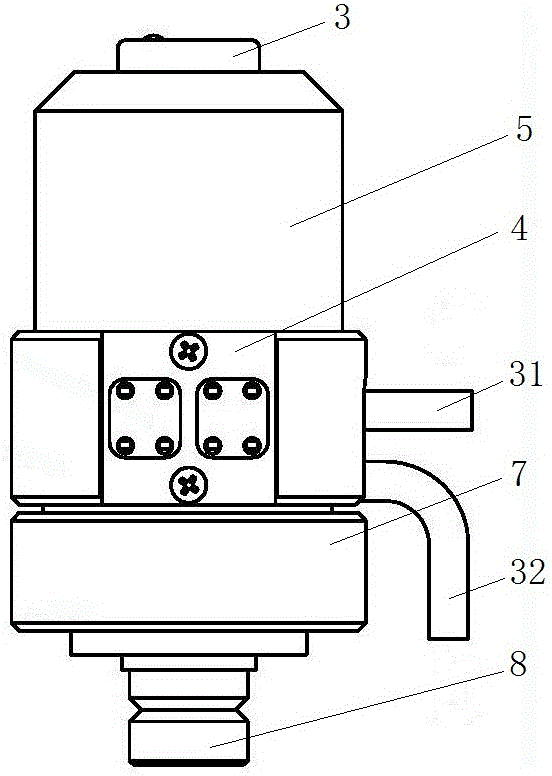

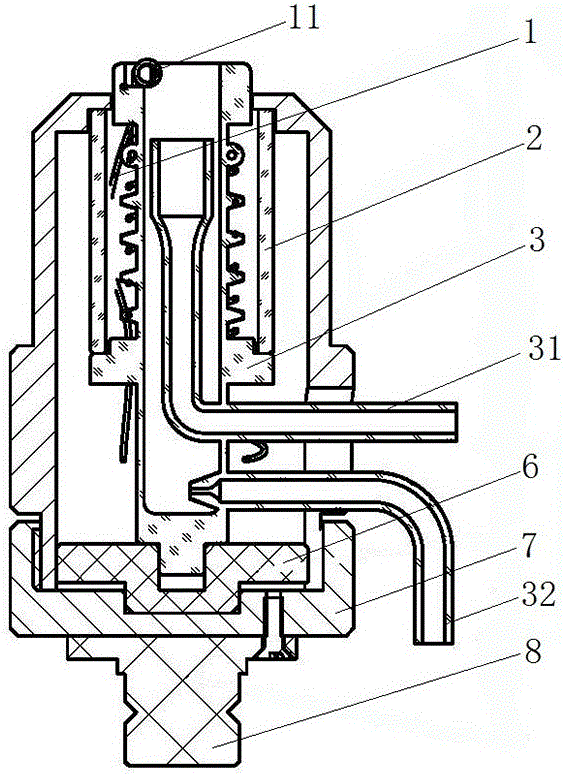

[0027] Such as figure 1 with figure 2 As shown, a self-heating atomizer of the present embodiment includes an atom generator 3 and a heating wire 1. The upper opening of the atom generator 3 is provided with an ignition coil 11, and the atom generator 3 is provided with an inner tube and an outer tube. , and a first side port 31 and a second side port 32, the first side port 31 communicates with the inner tube, and is drawn out from the bottom of the outer tube, and the second side port 32 is drawn out from the bottom of the outer tube. The top of the inner tube adopts a flaring design, and the connection between the outer tube and the second side port adopts a shrinking design; the heating wire 1 is wound on the outer wall of the upper part of the atom generator 3, and the part of the atom generator 3 wrapped around the heating wire 1 is provided with an insulating bushing 2. The insulating bush 2 covers the heating wire, and the outer wall of the atom generator 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com