Method for detecting incomplete root penetration of butt weld of thick-walled pipe in ferrite

A technology of butt weld and incomplete penetration, which is applied to the analysis of solids, materials, and instruments using sonic/ultrasonic/infrasonic waves. It can solve the problems of cumbersome operation and incomplete application, and achieve the effect of avoiding missed judgments and accurate judgments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

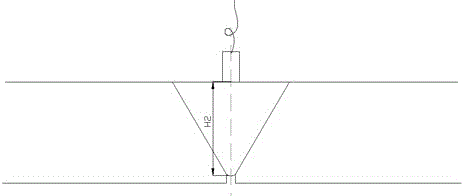

[0028] The detection method of this embodiment requires a digital ultrasonic detector, which uses a high-frequency transverse wave oblique probe and a high-frequency longitudinal wave straight probe. For on-site installation or in-service butt girth welding, single-sided welding and double-sided forming can only be performed on one side. Qualitative and quantitative detection of incomplete penetration of the root during detection, the specific steps are as follows:

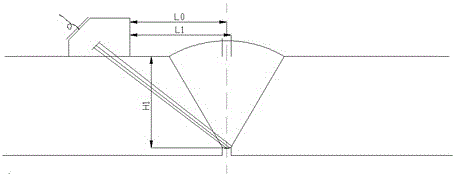

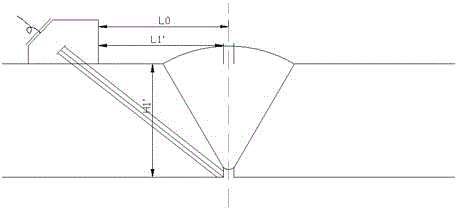

[0029] (1) Adjust the sensitivity parameters of the high-frequency shear-wave oblique probe according to the standard requirements; use the high-frequency shear-wave oblique probe to find the maximum reflection signal at the part of the root weld that exceeds the standard;

[0030] (2) Use a qualified steel ruler to locate the maximum reflection signal at the exceeding standard in the horizontal direction and vertical depth, and record the detection data, the horizontal distance L1, the vertical depth H1, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com