A method for predicting the dynamic recrystallization fraction of highly alloyed materials under time-varying conditions

A recrystallization and alloying technology, applied in the field of forging, can solve problems affecting prediction accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

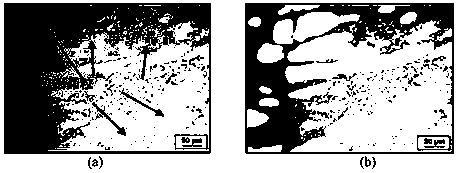

[0025] The present invention predicts the method for the dynamic recrystallization fraction of highly alloyed material under a kind of time-varying working condition, below with predicting typical highly alloyed material GH4169 alloy (its initial structure is as follows figure 1 Shown) dynamic recrystallization fraction is example, introduces in detail the specific implementation details of the prediction method that the present invention relates to, and its method comprises:

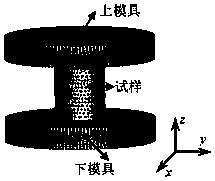

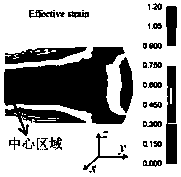

[0026] Step 1: Obtain the true stress-true strain curves of the GH4169 alloy under different deformation conditions and thermal simulation samples retaining the deformed structure through thermal compression simulation experiments at constant temperature and constant strain rate. The process parameters of the thermal simulation experiment at constant temperature and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com