Calcium fluoride (CaF2) induction crystallization process from rare-earth metal smelting high-fluoride wastewater

A rare earth metal, induced crystallization technology, used in metallurgical wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of insufficient reaction, slow sedimentation, and large actual consumption, and achieve improved sedimentation separation and crystallization. effect, accelerate reaction crystallization, reduce surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

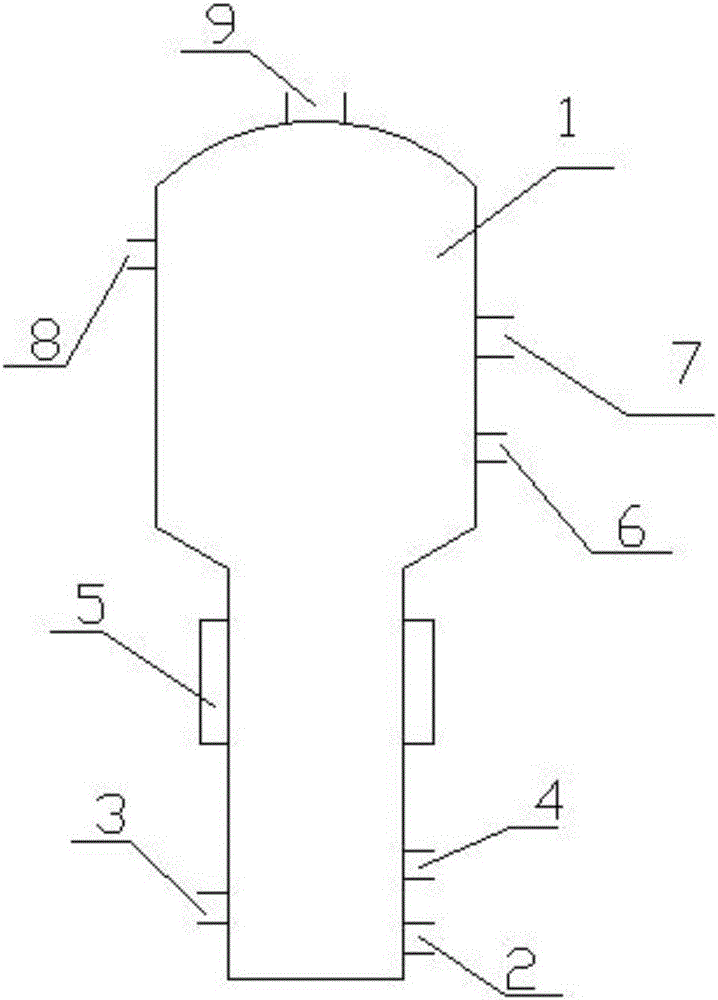

Method used

Image

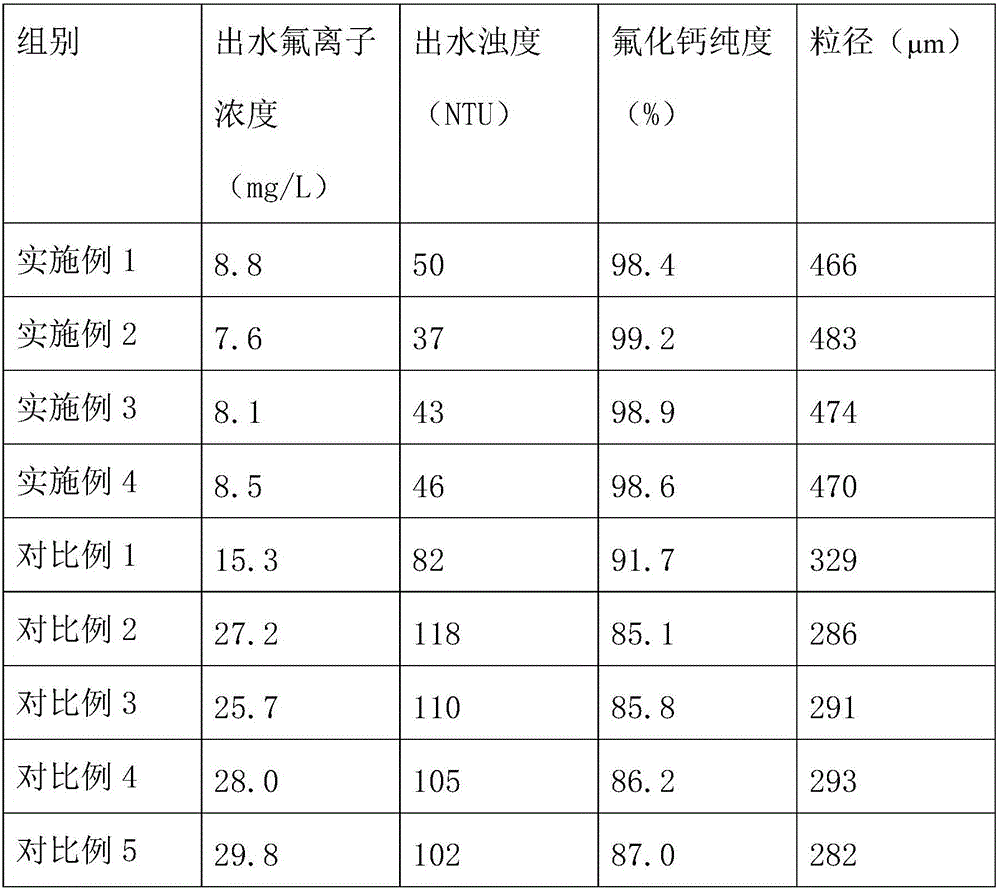

Examples

Embodiment 1

[0025] The process of inducing the crystallization of calcium fluoride in rare earth metal smelting high-fluorine wastewater, the specific steps are as follows:

[0026] (1) Fill 2g calcium fluoride seed crystal into the fluidized bed reactor, open 2.0m 3 The reflux water of / h flow rate makes the crystal seed in the reactor in a fluidized state at normal temperature;

[0027] (2) The high-fluorine wastewater with a fluorine content of 1.2g / L was treated with 0.5m 3 / h flow, calcium solution at 1.0m 3 / h flow rate, the temperature of the reflux water is raised to 70°C, and the waste water and the calcium solution are continuously reacted in the fluidized bed for 1 hour;

[0028] (3) Lower the temperature of the reflux water to 30°C, inject helium into the fluidized bed reactor, and use 1.2m of high-fluorine wastewater 3 / h flow, calcium solution at 2.5m 3 The flow rate of / h makes the waste water and calcium solution react in the fluidized bed for 0.5h;

[0029] (4) Conti...

Embodiment 2

[0036] The process of inducing the crystallization of calcium fluoride in rare earth metal smelting high-fluorine wastewater, the specific steps are as follows:

[0037] (1) Fill 10g calcium fluoride seed crystal into the fluidized bed reactor, open 2.5m 3 The reflux water of / h flow rate makes the crystal seed in the reactor in a fluidized state at normal temperature;

[0038] (2) The high-fluorine wastewater with a fluorine content of 2.2g / L was treated with 0.8m 3 / h flow, calcium solution at 1.5m 3 / h flow rate, the temperature of the reflux water is raised to 75°C, and the waste water and the calcium solution are continuously reacted in the fluidized bed for 1.2h;

[0039] (3) Lower the temperature of the reflux water to 35°C, inject helium into the fluidized bed reactor, and use 1.3m of high-fluorine wastewater 3 / h flow, calcium solution at 2.8m 3 The flow rate of / h makes the waste water and calcium solution react in the fluidized bed for 0.8h;

[0040] (4) Continu...

Embodiment 3

[0046] The process of inducing the crystallization of calcium fluoride in rare earth metal smelting high-fluorine wastewater, the specific steps are as follows:

[0047] (1) Fill 15g calcium fluoride seed crystal into the fluidized bed reactor, open 3.0m 3 The reflux water of / h flow rate makes the crystal seed in the reactor in a fluidized state at normal temperature;

[0048] (2) The high-fluorine wastewater with a fluorine content of 2.0g / L was treated with 0.5m 3 / h flow, calcium solution at 1.5m 3 / h flow rate, the temperature of the reflux water is raised to 80°C, and the waste water and the calcium solution are continuously reacted in the fluidized bed for 1.2h;

[0049] (3) Lower the temperature of the reflux water to 40°C, inject helium into the fluidized bed reactor, and use 1.5m of high-fluorine wastewater 3 / h flow, calcium solution at 2.5m 3 The flow rate of / h makes the waste water and calcium liquid react in the fluidized bed for 1h;

[0050] (4) Continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com