Propylene polymer compositions and processes for making the same

A technology of propylene copolymers and polymers, which is applied in the field of polymerization of in-situ reactor blends and compact in-situ blends, to achieve the effect of improving fatigue resistance and good melt flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1 The procedure for polymerizing the polymer composition is as follows. The polymerization was carried out in a pilot scale continuous loop liquid phase polymerization process employing two series reaction zones, each comprising one reactor. The reactor was jacketed to remove the heat of polymerization. The reactor temperature was set at 70°C in the first and second reaction zones. To facilitate addition to the reaction zone, the catalyst was slurried in oil (10 parts by weight catalyst with 90 parts by weight Drakeol® available from Penreco, Dickinson, Tex. TM 35). The catalyst was fed in a 10 wt% slurry at an estimated rate of 5 ml / hr. Triethylaluminum ("TEAL") was used as a scavenger and was fed at a rate of 3.8 ml / min at a concentration of 2 wt% in hexane solvent. A blend of two electron donors (a blend comprising approximately 5 mol% DCPMS and 95 mol% PTES, based on the total mol% of the electron donor) in hexane solution at a concentration of 0.072 wt...

Embodiment 2

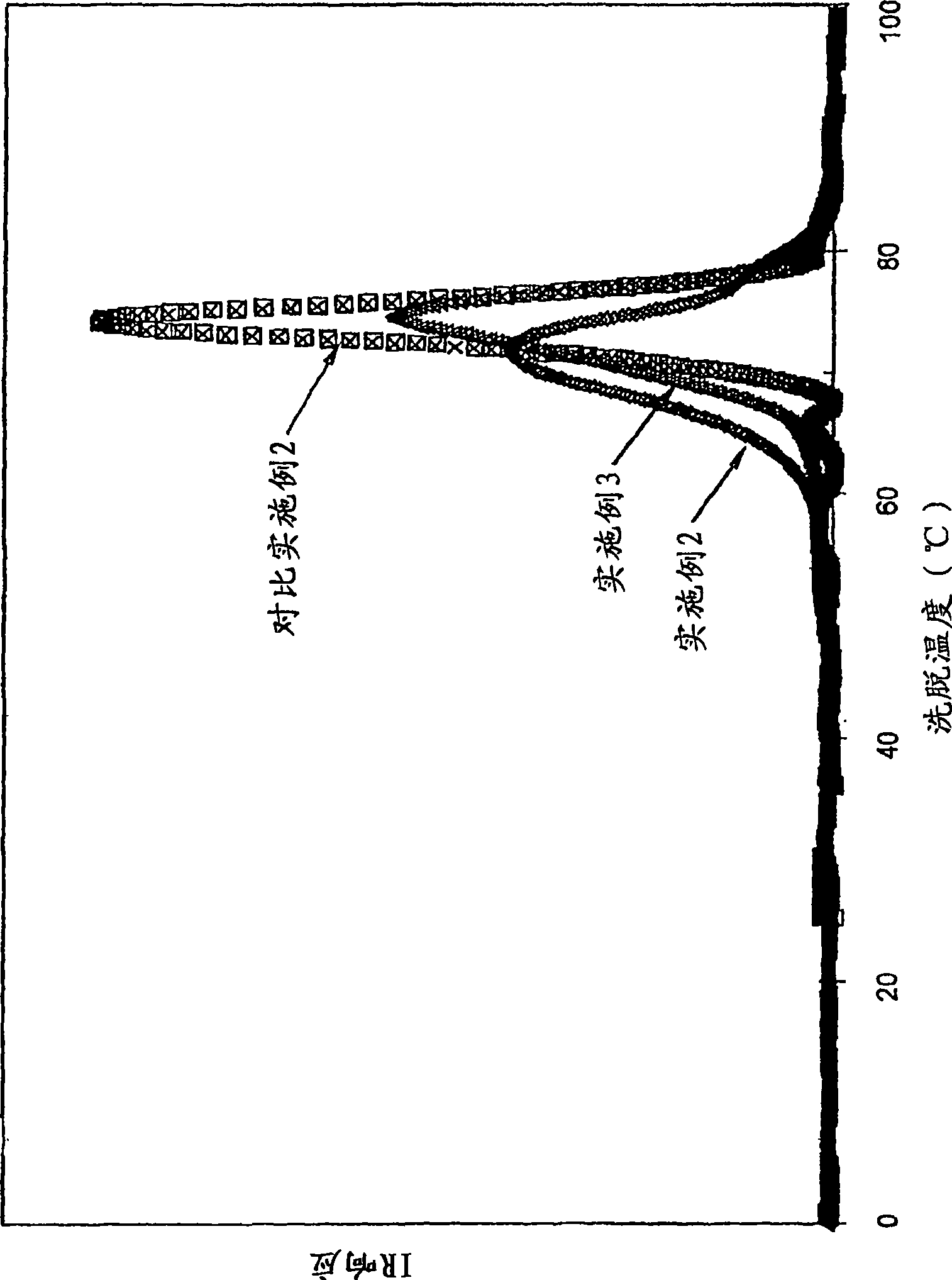

[0069] The polymer, Example 2, was prepared using the same catalyst and polymerization procedure as described above for Example 1 . The difference was to increase the electron donor feed to 4.0 wppm, based on the total wppm of donor in propylene, adjust the hydrogen feed rate so that the MFR of the polymer in the first reaction zone was about 1.0 dg / min and that of the polymer in the second reaction zone The MFR is about 6.8 dg / min with a production split of 49% in the first reaction zone and 51% in the second reaction zone.

Embodiment 3

[0070] The polymer, Example 3, was prepared using the same catalyst and polymerization procedure as described above for Example 1 . The only differences were increasing the electron donor feed to 9.1 wppm, based on the total wppm of donor in propylene, and adjusting the hydrogen feed rate so that the MFR of the polymer in the first reaction zone was about 0.9 dg / min and the second reaction zone The MFR of the polymer was about 6.1 dg / min with a production split of 45% in the first reaction zone and 55% in the second reaction zone.

PUM

| Property | Measurement | Unit |

|---|---|---|

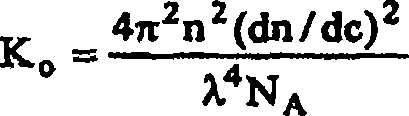

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com